Filling and mining trapezoidal lane-side support body and support method

A roadside support and support body technology, which is applied in the direction of filling, mining equipment, earthwork drilling and mining, etc., can solve the problems such as the stability and strength need to be strengthened, the lateral thrust is large, and the horizontal deformation of the roadside support body is large. To achieve the effect of increasing the recovery rate of coal resources, reducing deformation, and promoting sustainable green development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation of the present invention will be further described below in conjunction with a certain mining area:

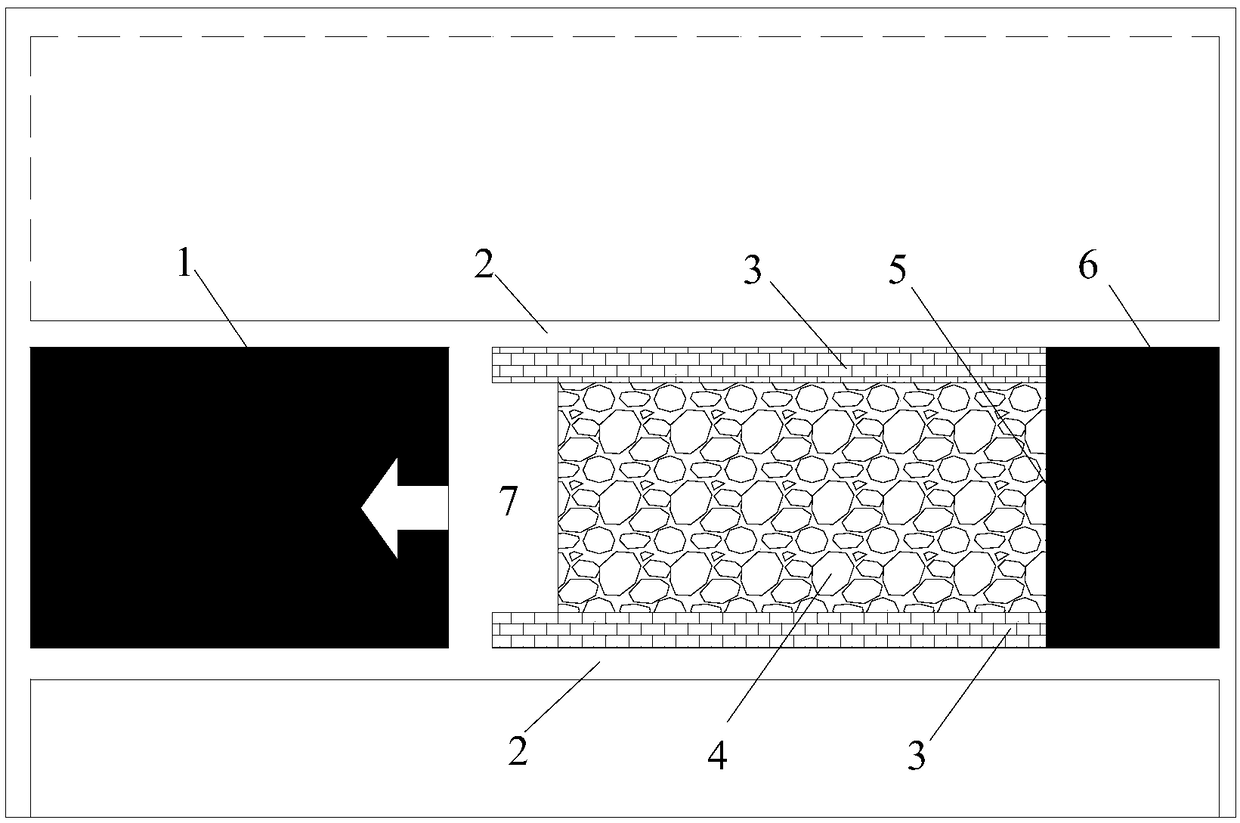

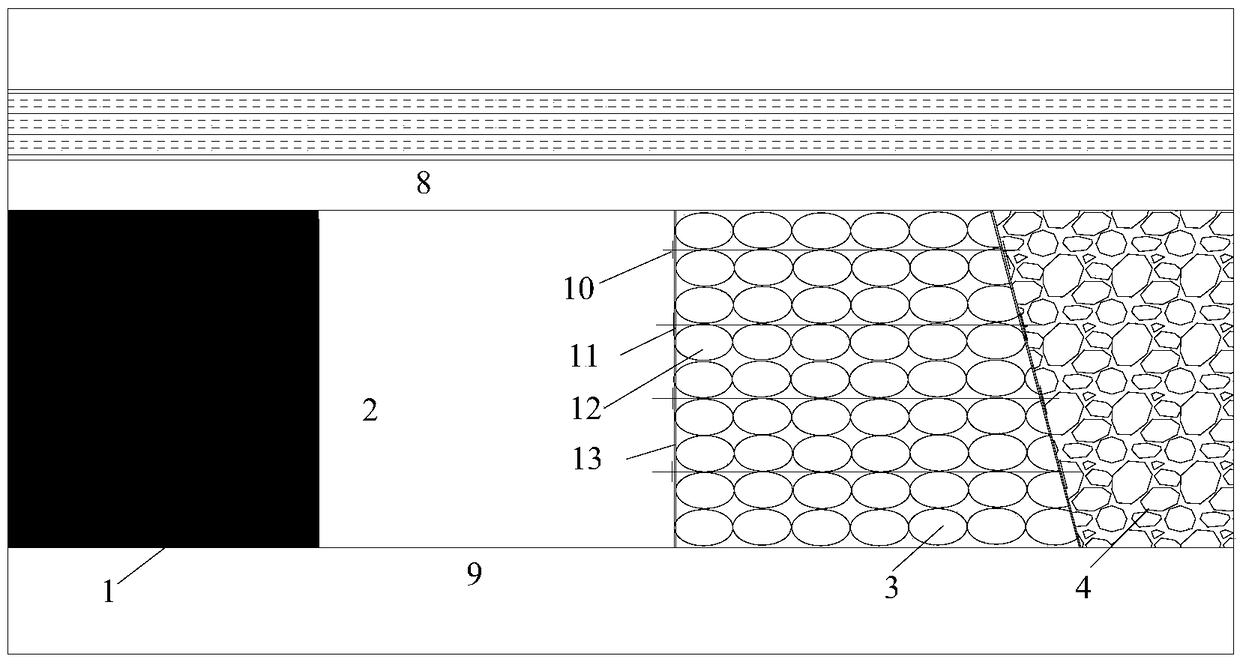

[0025] like figure 1 As shown, a trapezoidal roadside support body for filling mining is characterized in that: the roadside support body 3 is a gangue wall arranged between the gob-side entry retention 2 and the goaf filling body 4, and the gangue The side of the wall is a right-angled trapezoidal structure. The gangue wall is formed by stacking gangue bags 12 filled with gangue. In the gangue bag 12, a plurality of double-ended threaded anchor rods 10 are arranged at intervals in the transverse direction. The metal mesh 11 is sprayed with a concrete layer 13 on the metal mesh 11 to ensure the strength and stability of the roadside support body 3. When the height of the roadside support body 3 is 2.73-4.37m, the ratio of its width to height is 1: 1. The angle between the oblique waist and the lower bottom is 75°-85°, and the length of the upper base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com