Preparation method and application of micro-nano cellulose

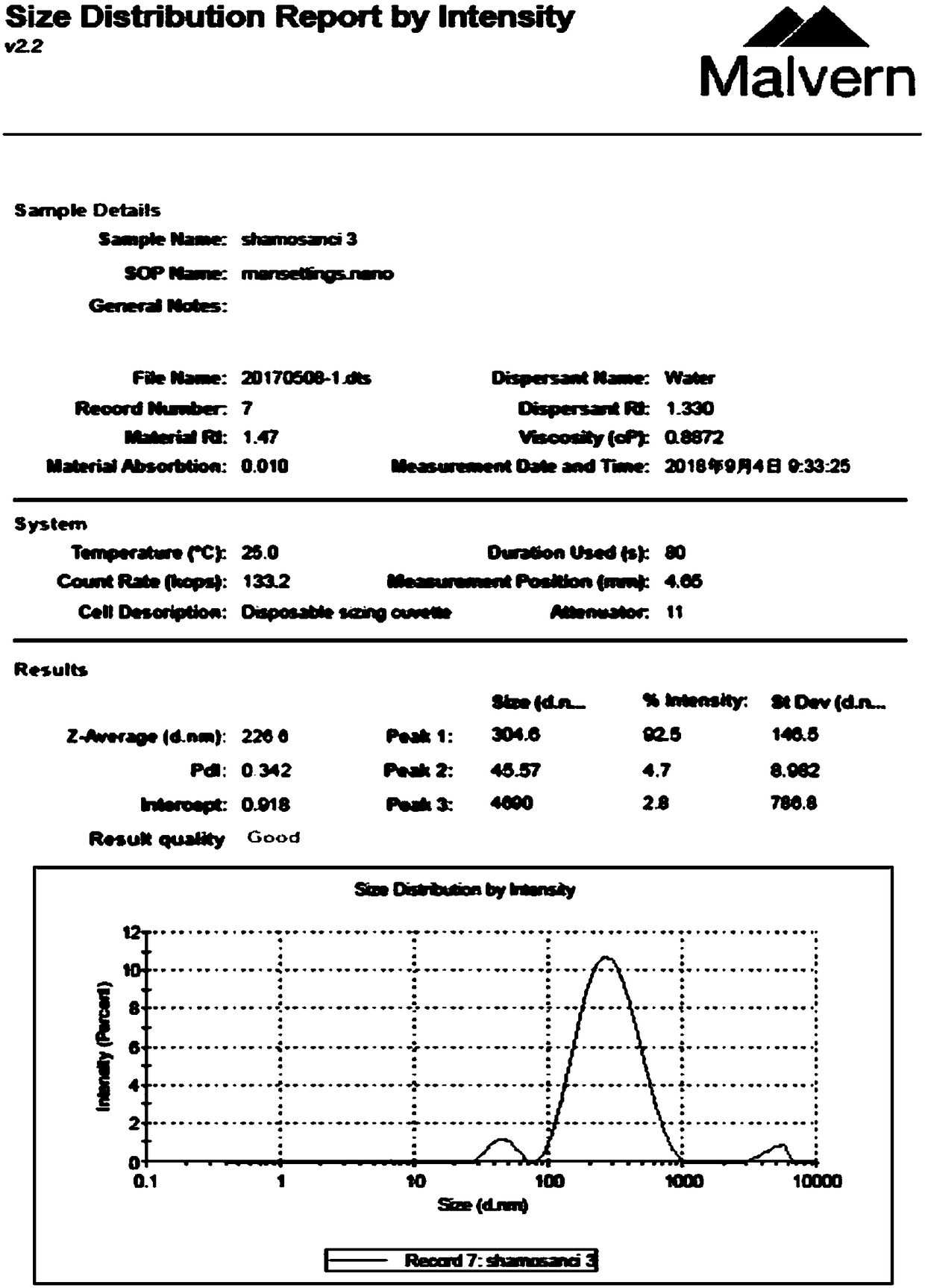

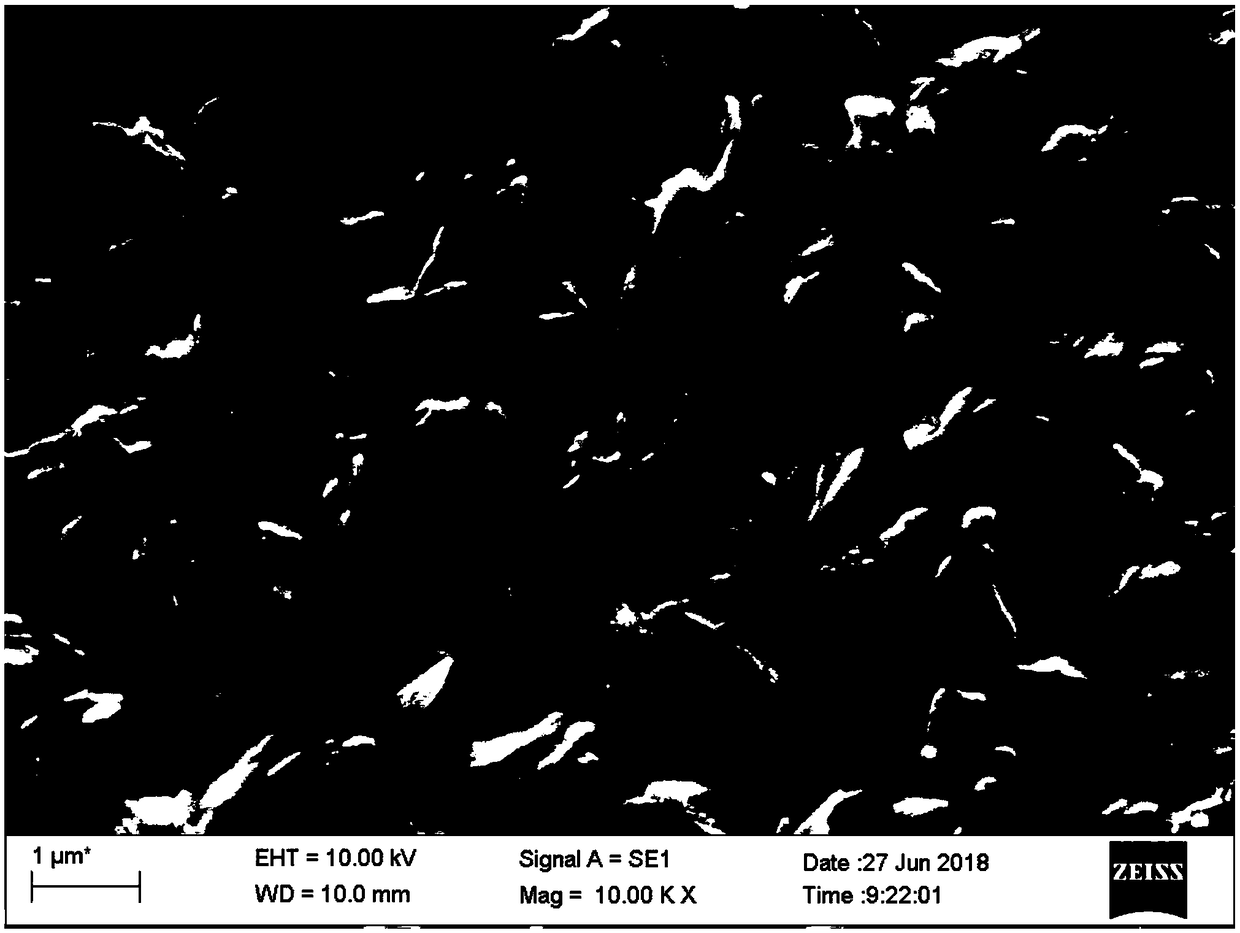

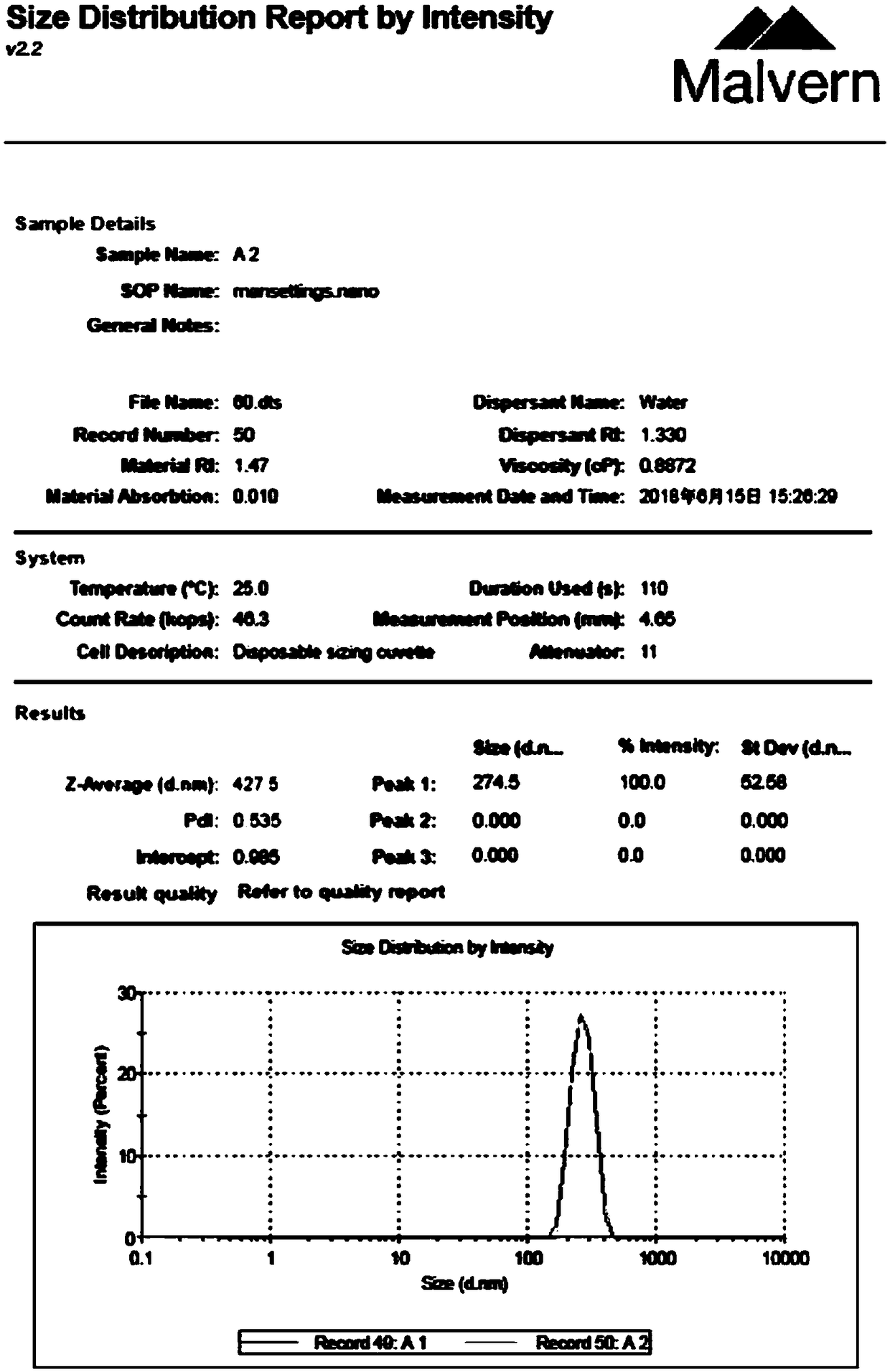

A technology of micro-nano cellulose and plant fibers, applied in the field of materials, can solve the problems of high energy consumption, incomplete reaction, low yield, etc., and achieve the effect of good particle size uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The hydrolysis agent is obtained by mixing methanesulfonic acid: sulfuric acid: water = mass ratio 36:40:24.

[0039] Mix 50 grams of hydrolyzing agent and 1 gram of cotton, react at 25°C, and the reaction time is half an hour. The obtained reaction product is diluted with 10 times the volume of water and becomes light blue. After one day, there is no precipitation, indicating that the obtained product is nano-scale Cellulose, no yellowing by-products.

Embodiment 2

[0041] The hydrolysis agent is obtained by mixing methanesulfonic acid: sulfuric acid: water = mass ratio 36:40:24.

[0042] Mix 50 grams of hydrolyzing agent and 1.5 grams of hardwood pulp (poplar wood pulp) and react at 25°C for half an hour. The obtained reaction product is diluted with 10 times the volume of water and becomes light blue, and there is no precipitation after standing for one day , indicating that nanoscale cellulose was obtained without yellowing by-products.

[0043] Note: The crystallinity of hardwood cellulose is only over 50%, and the crystallinity of cotton cellulose is above 90%. Hardwood cellulose is more easily hydrolyzed by acid.

Embodiment 3

[0045] The hydrolysis agent is obtained by mixing methanesulfonic acid: sulfuric acid: water = mass ratio 36:40:24.

[0046] Mix 50 grams of hydrolyzing agent and 1.5 grams of ground wood powder (200 mesh coniferous wood powder, pine wood powder) and react at 25°C for half an hour. No carbonization; the reaction product was centrifuged at 5000 rpm for 5 minutes to remove the acid-insoluble lignin in the upper layer; then 50 ml of the supernatant was removed and mixed with 5 grams of activated carbon, shaken for three minutes for decolorization, and after standing for more than one day, it was determined that A light blue non-precipitating solution indicated that nanocellulose was obtained. Nanocellulose and acid-insoluble lignin can also be separated by ceramic nanofiltration membrane, and the lignin obtained in this way is also of great market value.

[0047] Note: The crystallinity of coniferous wood cellulose is about 70%, which is lower than that of cotton cellulose and e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com