High-permeability magnetic soft-contact two-stage copper alloy crystallizer and its preparation and application

A technology of copper alloy and crystallizer, which is applied in the field of high-permeability magnetic soft-contact two-stage copper alloy crystallizer, can solve the problems of insufficient joint strength at the welding seam of the mold, achieve good cooling effect, reduce the occurrence of billet defects, The effect of reducing the accident rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A copper alloy is a high-permeability copper alloy, which includes components and the mass percentage of each component: Al is 0.3%, Mn is 32%, Ti<0.5%, Si<0.5%, and the balance is Cu.

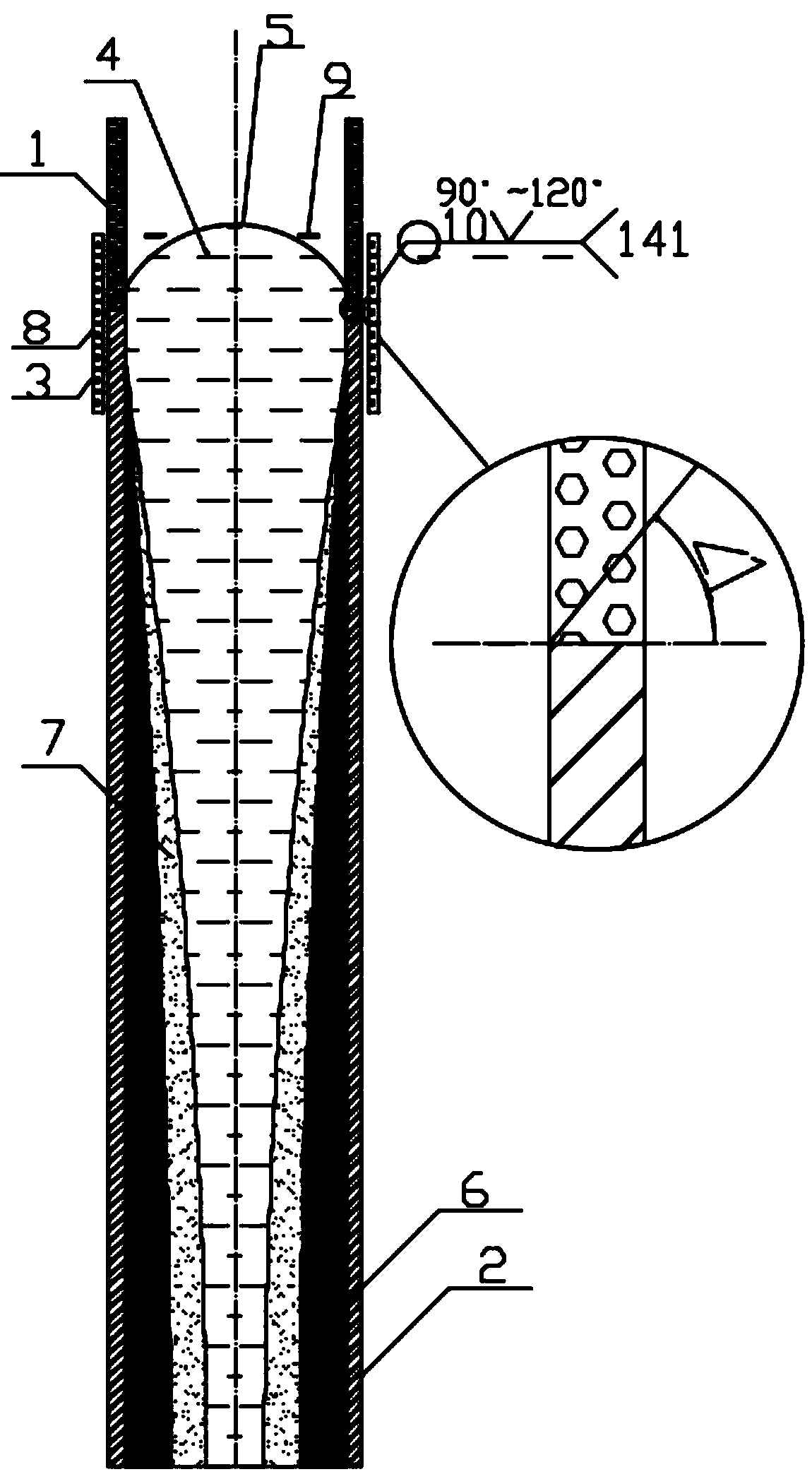

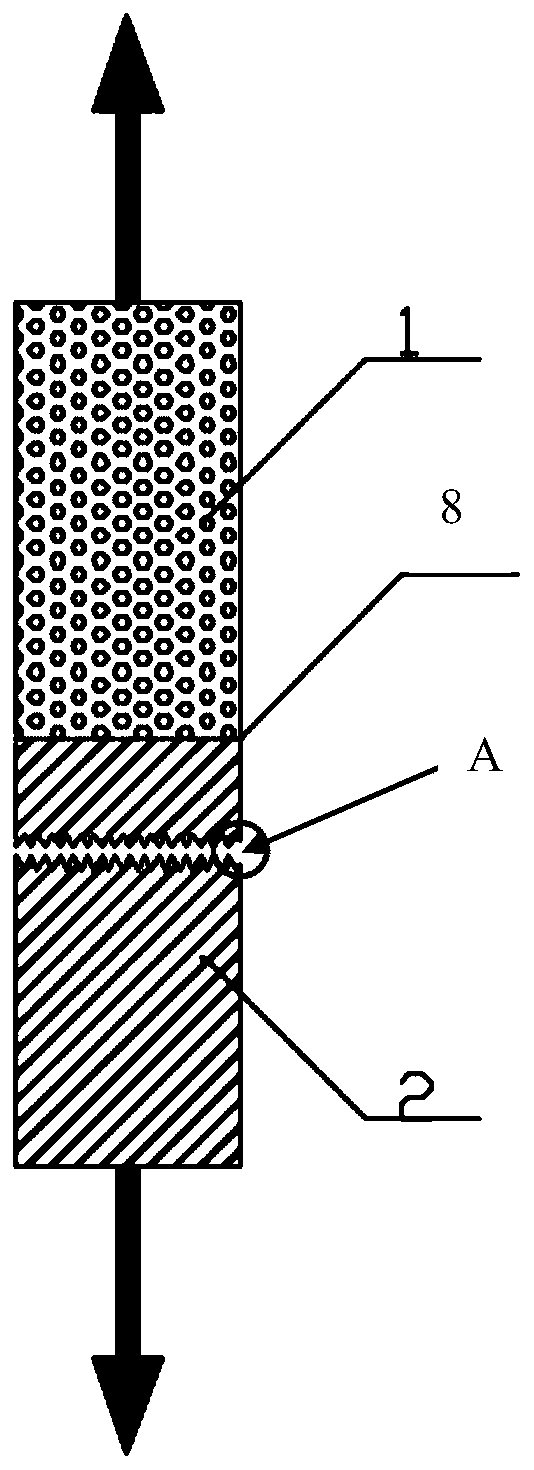

[0057] A high-permeability magnetic soft-contact two-stage copper alloy crystallizer, its overall longitudinal section view is shown in figure 1 The high-permeability magnetic soft-contact two-stage copper alloy crystallizer includes the first half of the high-permeability magnetic soft-contact two-stage copper alloy crystallizer made of the above-mentioned high-permeability copper alloy, and the high-permeability magnetic soft-contact two-stage copper alloy crystallizer made of pure copper. The lower half section 2 of the one-stage copper alloy crystallizer, the joint 8 between the upper half section 1 of the high-permeability magnetic soft-contact two-stage copper alloy crystallizer and the lower half section 2 of the high-permeability magnetic soft-contact two-stage copper alloy cryst...

Embodiment 2

[0085] A copper alloy is a high-permeability copper alloy, which includes components and the mass percentage of each component: Al is 0.2%, Mn is 31.5%, Ti<0.5%, Si<0.5%, and the balance is Cu.

[0086] A high-permeability magnetic soft-contact two-stage copper alloy crystallizer, same as embodiment 1.

[0087] A method for preparing a high-permeability magnetic soft-contact two-stage copper alloy crystallizer, comprising the following steps:

[0088] Step 1: Casting the upper half of a high-permeability magnetic soft-contact two-stage copper alloy crystallizer

[0089] High-purity electrolytic aluminum, electrolytic manganese, electrolytic copper, sponge titanium and industrial silicon, according to the mass percentage: Al<2%, Mn31.5%, Ti<0.5%, Si<0.5%, the balance is Cu, called After measuring, mix them and put them into a graphite crucible; put the graphite crucible into a vacuum induction furnace and evacuate; turn on the induction heating equipment, wait for the alloy to...

Embodiment 3

[0099] A copper alloy is a high-permeability copper alloy, which includes components and the mass percentage of each component: Al is 0.4%, Mn is 33%, Ti<0.5%, Si<0.5%, and the balance is Cu.

[0100] A high-permeability magnetic two-stage soft-contact crystallizer, including the upper half of the high-permeability magnetic soft-contact two-stage copper alloy crystallizer made of high manganese copper alloy 1, the high-permeability magnetic soft-contact two-stage made of pure copper The lower half section 2 of the one-stage copper alloy crystallizer, the upper half section 1 of the high-permeability magnetic soft-contact two-stage copper alloy crystallizer and the lower half section 2 of the high-permeability magnetic soft-contact two-stage copper alloy crystallizer pass through a V-shaped groove The way of welding, the welding wire is made of pure copper. The angle (∠1) between the upper half of the weld and the horizontal direction of the high-permeability magnetic soft-cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com