Preparation method of polyolefin packaging film for solar cell module

A technology of solar cells and polyolefins, applied in electrical components, circuits, photovoltaic power generation, etc., can solve problems such as yellowing, photovoltaic module output power drop, etc., to prevent yellowing and aging, reduce residual monomers, and reduce initiators and the effect of monomer addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

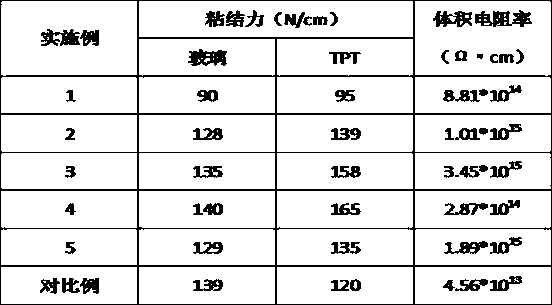

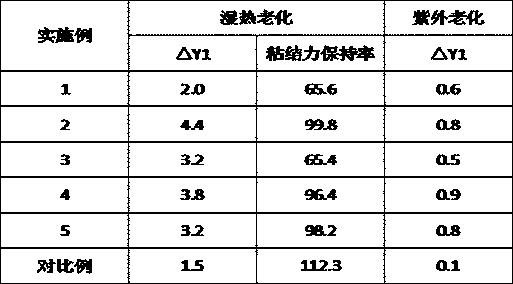

Embodiment 1

[0021] A method for preparing a polyolefin encapsulation film for solar cell modules,

[0022] (1) 91 parts of modified polyolefin resin, 0.5 parts of crosslinking agent, 0.8 parts of silane coupling agent, 0.12 parts of antioxidant, 0.12 parts of ultraviolet light absorber, 0.2 parts of light stabilizer, 0.02 parts of dispersant, initiator Add 0.01 parts of the agent into the stirring device, mix evenly, and then add it to the single-screw extruder for reaction extrusion. The extrusion temperature of the screw extruder is controlled at 80°C, and the screw speed is 20rpm, and then through extrusion, casting, Cooling to form a film, the modified polyolefin resin is an unsaturated polyolefin containing double bonds, wherein the double bonds account for 18% of the total weight of the unsaturated polyolefin; wherein, the initiator is selected from cumene hydroperoxide; the crosslinking agent Including the main cross-linking agent and cross-linking auxiliary agent, the cross-linkin...

Embodiment 2

[0025] A method for preparing a polyolefin encapsulation film for solar cell modules,

[0026] (1) 95 parts of modified polyolefin resin, 4.5 parts of crosslinking agent, 0.8 part of silane coupling agent, 0.12 part of antioxidant, 0.12 part of ultraviolet light absorber, 0.2 part of light stabilizer, 0.02 part of dispersant, initiator Add 0.01 parts of the agent into the stirring device, mix evenly, and then add it to the single-screw extruder for reaction extrusion. The extrusion temperature of the screw extruder is controlled at 80°C, and the screw speed is 20rpm, and then through extrusion, casting, Cooling to form a film, the modified polyolefin resin is an unsaturated polyolefin containing double bonds, wherein the double bonds account for 18% of the total weight of the unsaturated polyolefin; wherein, the initiator is selected from cyclohexanone peroxide, and the crosslinking agent includes The main cross-linking agent and cross-linking auxiliary agent, the cross-linkin...

Embodiment 3

[0029] A method for preparing a polyolefin encapsulation film for solar cell modules,

[0030](1) 93 parts of modified polyolefin, 2.5 parts of crosslinking agent, 1.8 parts of silane coupling agent, 0.24 parts of antioxidant, 0.18 parts of ultraviolet light absorber, 0.5 parts of light stabilizer, 0.05 parts of dispersing agent, initiator Add 0.02 parts into the stirring device, mix evenly, and then add it to a single-screw extruder for reaction extrusion. Control the extrusion temperature of the screw extruder to 90°C, and the screw speed to 25rpm, and then pass extrusion, casting, and cooling Forming a film, the modified polyolefin resin is an unsaturated polyolefin containing double bonds, wherein the double bonds account for 20% of the total weight of the unsaturated polyolefin; wherein, the initiator is selected from cumene hydroperoxide and peroxide-2 -A mixture of tert-amyl ethylhexyl carbonate, the mass ratio of which is 1:1; the cross-linking agent includes a main cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com