Method for preparing vanadium pentoxide-based nanosheets

A vanadium pentoxide-based, nanosheet technology, applied in vanadium oxide, tin oxide and other directions, can solve the problems that have not been found, and achieve the effects of good morphology stability, high specific surface area and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

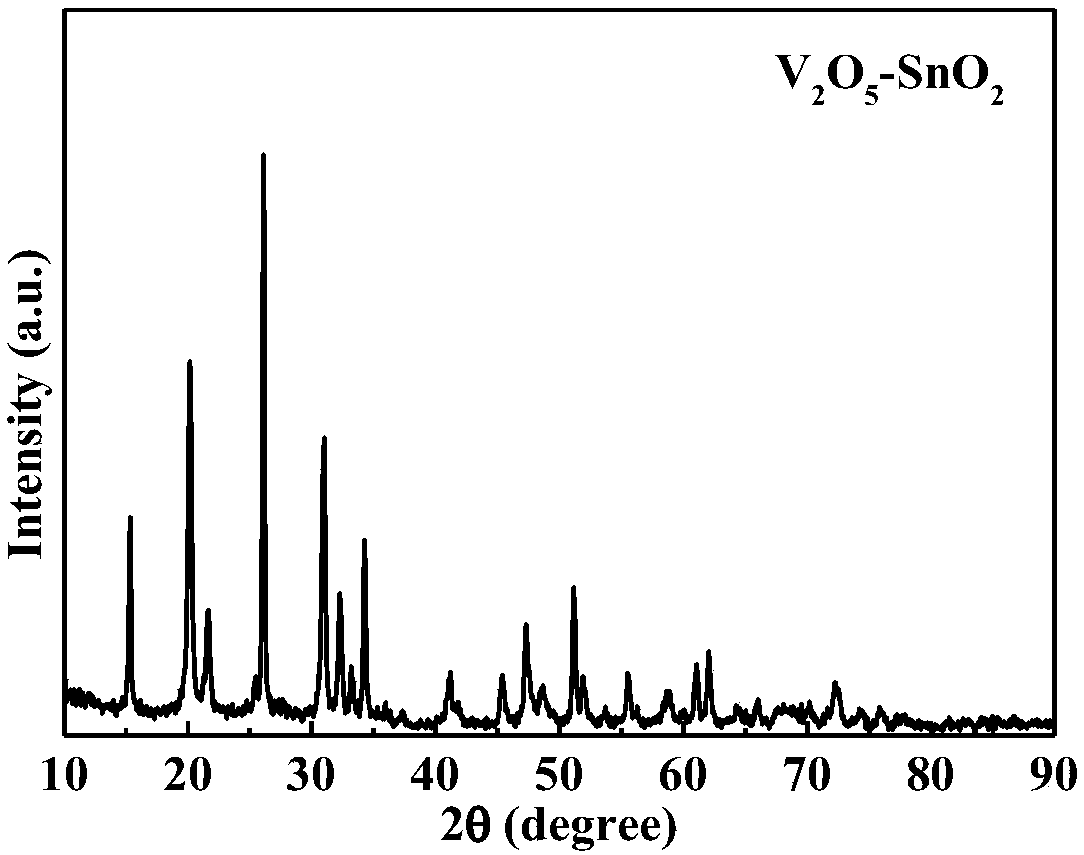

[0022] Dissolve 173.5mg vanadium triacetylacetonate and 14.4 tin tetrachloride pentahydrate in 40mL N,N-dimethylformamide, and magnetically stir for 1 to 2 hours until a uniform and transparent solution is formed, then transfer the solution to 50mL polytetrafluoroethylene In a stainless steel autoclave lined with vinyl fluoride, the autoclave was placed in an oven for reaction. After the reaction, the solution was washed with absolute ethanol several times to obtain a black solid, and then the solid was dried at 80°C for 6 hours, put the ground powder in a 400°C muffle furnace for calcination for 2 hours, and finally get V 2 o 5 -SnO 2 Nanosheets.

Embodiment 2

[0024] Dissolve 174.5 mg of vanadium triacetylacetonate and 14.8 mg of tin tetrachloride pentahydrate in 40 mL of N,N-dimethylformamide, and stir magnetically for 1 to 2 hours until a uniform and transparent solution is formed, then transfer the solution to 50 mL of poly In a stainless steel autoclave lined with tetrafluoroethylene, and place the autoclave in an oven for reaction, after the reaction, wash the solution with absolute ethanol several times to obtain a black solid, and then dry the solid at 80 °C After 6 hours, the ground powder was calcined in a muffle furnace at 400°C for 2 hours to obtain V 2 o 5 -SnO 2 Nanosheets.

Embodiment 3

[0026] Dissolve 174.5 mg of vanadium triacetylacetonate and 14.8 mg of tin tetrachloride pentahydrate in 40 mL of N,N-dimethylformamide, and stir magnetically for 1 to 2 hours until a uniform and transparent solution is formed, then transfer the solution to 50 mL of poly In a stainless steel autoclave lined with tetrafluoroethylene, and place the autoclave in an oven for reaction, after the reaction, wash the solution with absolute ethanol several times to obtain a black solid, and then dry the solid at 80 °C After 6 hours, the ground powder was calcined in a muffle furnace at 500°C for 2 hours to obtain V 2 o 5 -SnO 2 Nanosheets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com