A method for preparing zeolite granular material from washed coal gangue

A technology for granular materials and coal gangue, which is applied in the field of solid waste resource utilization and water treatment materials, can solve the problems of complex preparation process, shortage, secondary pollution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

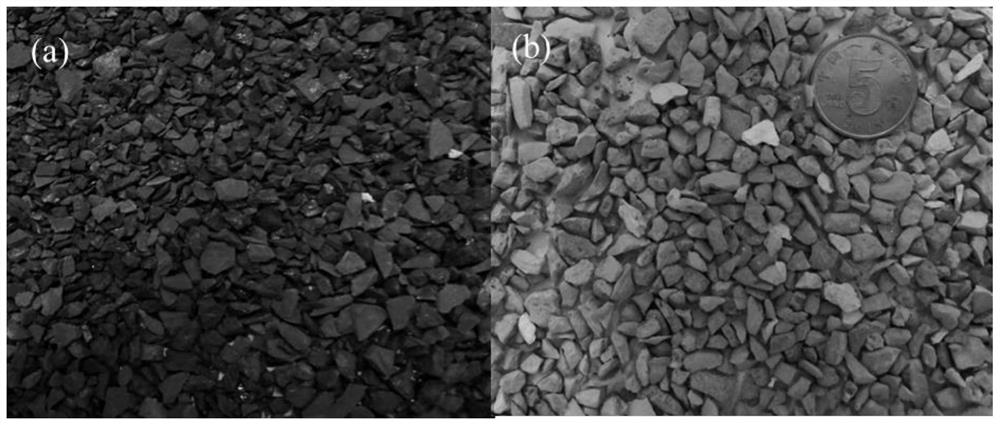

[0029] (1) After the washed coal gangue is crushed by a roller crusher and passed through a 10mm sieve (the photo is shown in figure 1 As shown in (a), calcined in a muffle furnace at 650 ° C for 1 h to basically oxidize the organic matter and transform kaolinite into metakaolinite.

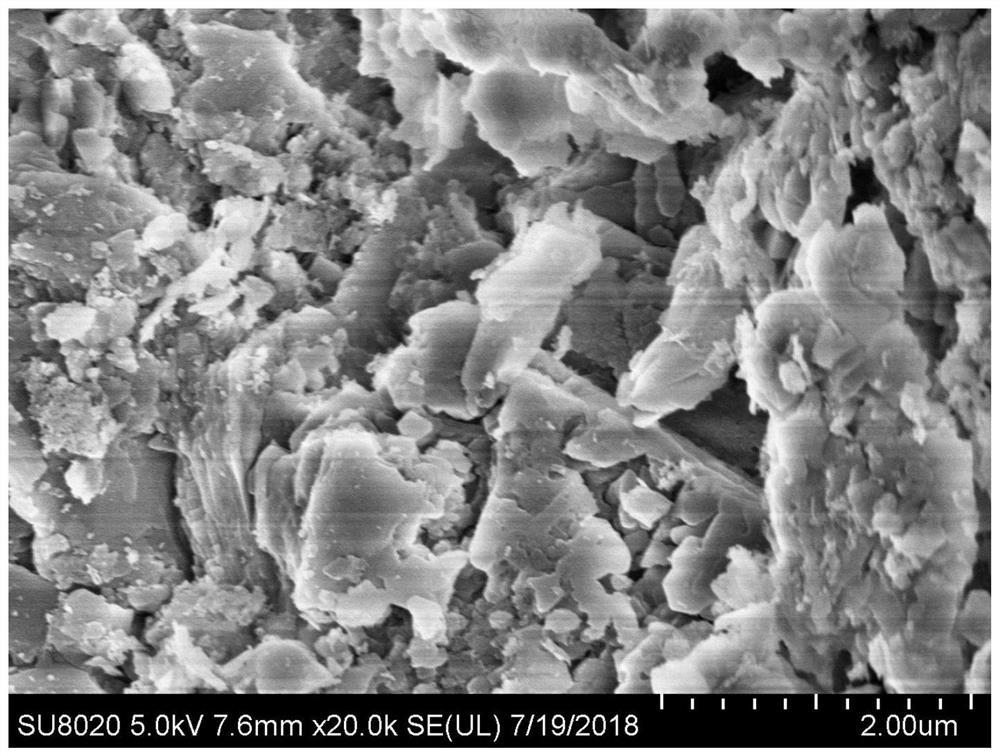

[0030] (2) The calcined ash is selectively crushed and sieved to obtain porous particles with a particle size of 3 to 5 mm (the photo is as follows: figure 1 As shown in (b), the SEM image is as figure 2 shown).

[0031] (3) Prepare a sodium hydroxide solution with a mass concentration of 15%, weigh the particles according to the mass volume ratio of the particles to the sodium hydroxide solution 1g:2mL, and put them into a reaction vessel.

[0032] (4) Put the reaction vessel into a water bath and raise the temperature to 90°C, keep it warm for 24 hours. During the reaction, use a pump to pump the solution from the bottom of the reactor to the top of the reactor, so that the solution in the r...

Embodiment 2

[0036] (1) After crushing 10kg of washed coal gangue with a roller crusher and passing through a 10mm sieve, it was calcined in a muffle furnace at 800°C for 1 hour to oxidize and decompose organic matter and transform kaolinite into metakaolinite.

[0037] (2) The calcined ash is processed in a drum type jar mill for 1 hour to be selectively crushed, and sieved to obtain particles with a particle size greater than 2 mm;

[0038] (4) preparation mass concentration is the sodium hydroxide solution of 10%, according to the ratio batching of particle and sodium hydroxide solution mass volume ratio 1g:3mL, puts into reaction container and seals;

[0039] (5) Put the reaction vessel into the oven, set the temperature at 95°C, and keep it warm for 12 hours. During the reaction, pump the solution from the bottom of the reactor and transport it to the top of the reactor, so that the solution in the reactor flows through the particles in a seepage manner. Material, to achieve liquid mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com