Silicon carbide crystal rapid orientation method

A silicon carbide crystal and silicon carbide technology, which is applied in the field of rapid orientation of silicon carbide crystals, can solve the problems of long time consumption, cumbersome operability, low precision, etc., and achieve the effects of short time consumption, low operating requirements for personnel, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

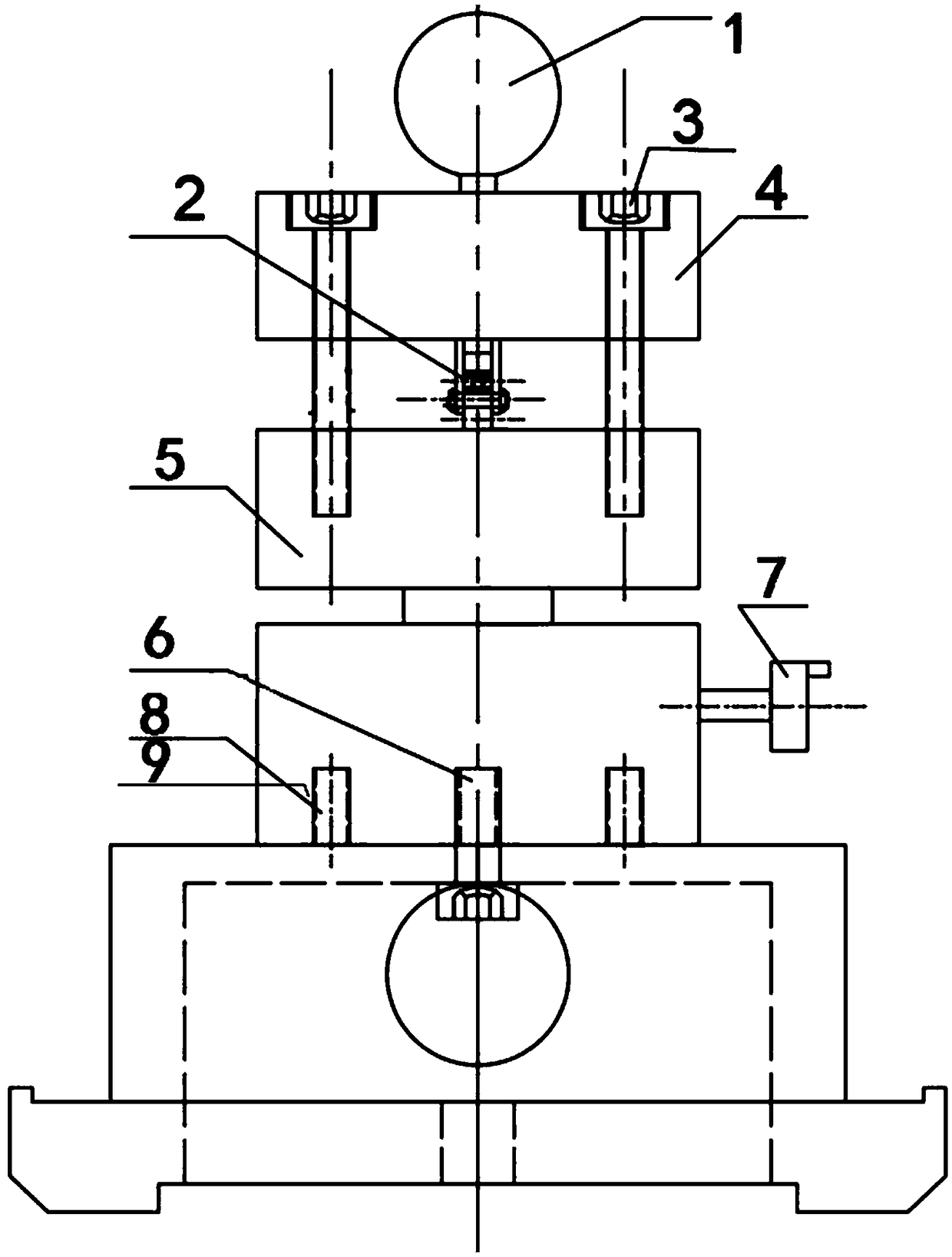

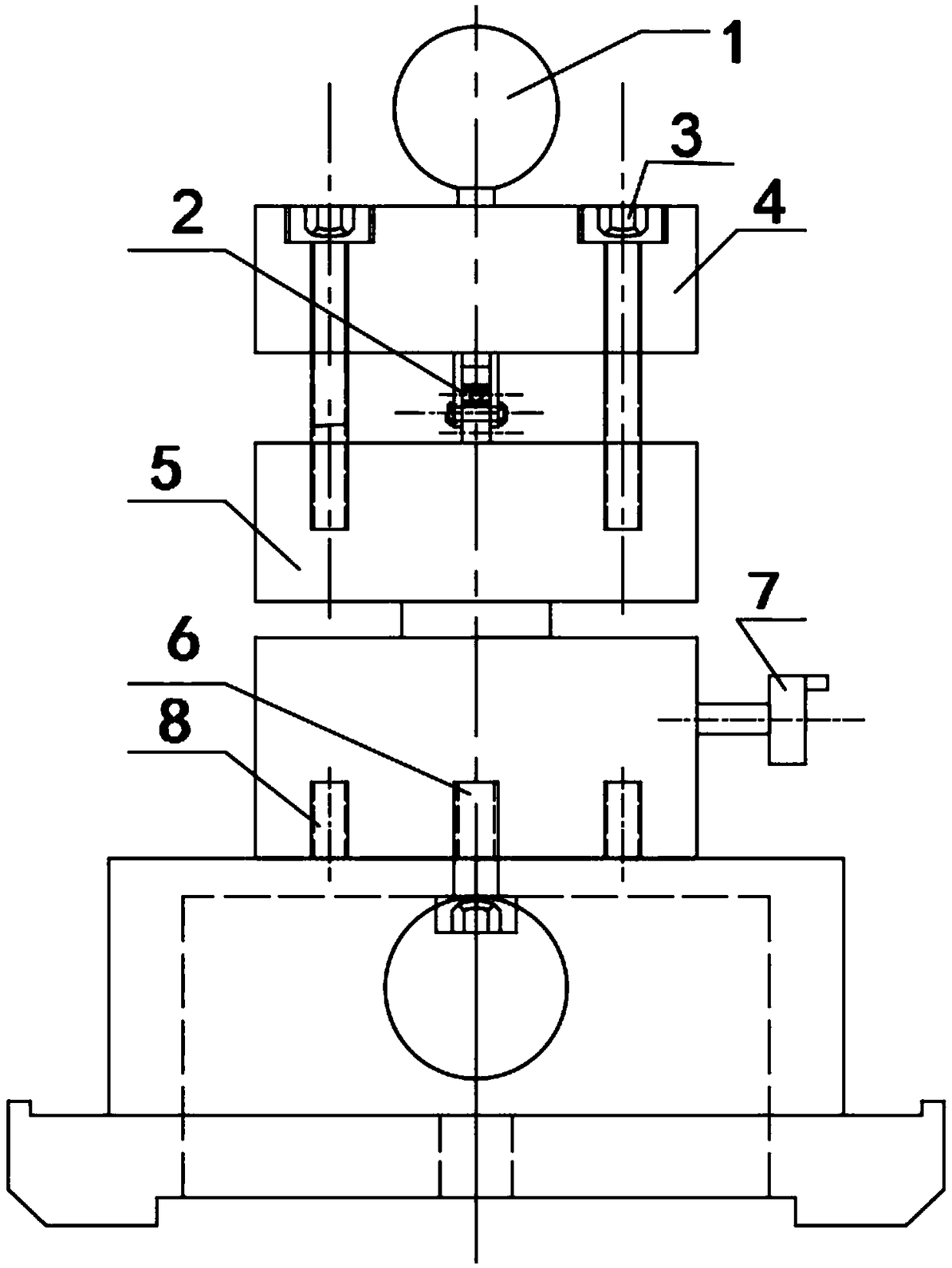

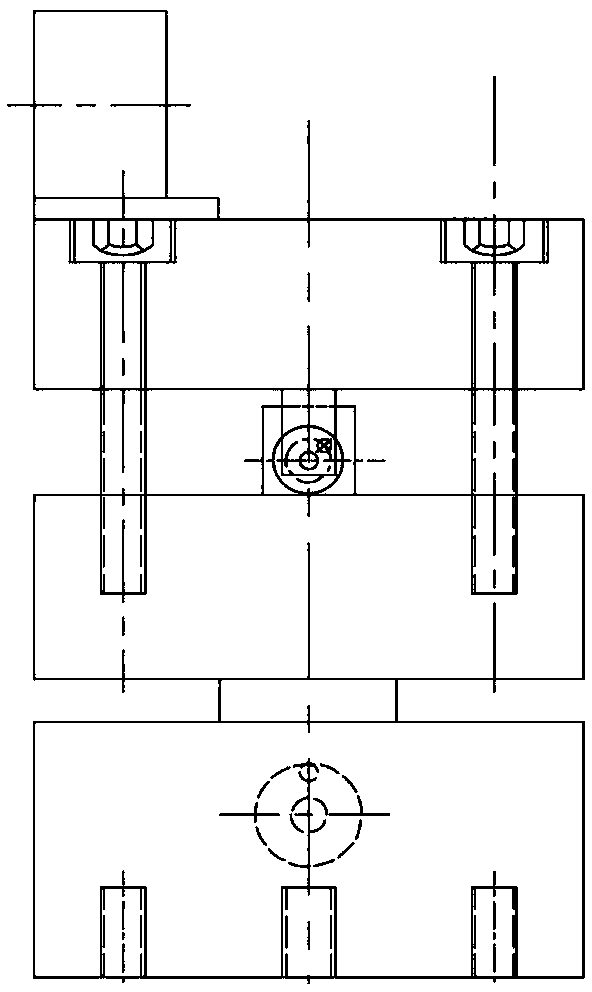

[0038]A method for quickly orienting silicon carbide crystals, using an orienting jig before cutting to control the vertical and horizontal movements of the upper platform and the lower platform, respectively, to fix the silicon carbide crystal rods in the vertical and horizontal directions, and realize the carbonization Measurement of the horizontal and vertical angles of silicon crystal rods; a method for rapid orientation of silicon carbide crystals, comprising the following steps:

[0039] S10, stick the silicon carbide ingot on the upper platform of the pre-cutting orienting fixture, and place it for 5 minutes. After the glue is cured, pass the pre-cutting orienting fixture of the bonded silicon carbide ingot through the screw and the pre-cutting orienting fixture The threaded hole is fastened on the X-Ray orientation instrument;

[0040] S20, adjust the adjustment screw on the upper platform to make the upper platform move in the vertical direction, and look for the high...

Embodiment 2

[0053] A method for quickly orienting silicon carbide crystals, using an orienting jig before cutting to control the vertical and horizontal movements of the upper platform and the lower platform, respectively, to fix the silicon carbide crystal rods in the vertical and horizontal directions, and realize the carbonization Measurement of the horizontal and vertical angles of silicon crystal rods; a method for rapid orientation of silicon carbide crystals, comprising the following steps:

[0054] S10, stick the silicon carbide ingot on the upper platform of the pre-cutting directional fixture, and place it for 8 minutes. After the glue is cured, pass the pre-cutting directional fixture of the bonded silicon carbide ingot through the screw and the pre-cutting directional fixture The threaded hole is fastened on the X-Ray orientation instrument;

[0055] S20, adjust the adjustment screw on the upper platform to make the upper platform move in the vertical direction, and look for t...

Embodiment 3

[0068] A method for quickly orienting silicon carbide crystals, using an orienting jig before cutting to control the vertical and horizontal movements of the upper platform and the lower platform, respectively, to fix the silicon carbide crystal rods in the vertical and horizontal directions, and realize the carbonization Measurement of the horizontal and vertical angles of silicon crystal rods; a method for rapid orientation of silicon carbide crystals, comprising the following steps:

[0069] S10, stick the silicon carbide ingot on the upper platform of the pre-cutting directional fixture, and place it for 6 minutes. After the glue is cured, pass the pre-cutting directional fixture of the bonded silicon carbide ingot through the screw and the pre-cutting directional fixture The threaded hole is fastened on the X-Ray orientation instrument;

[0070] S20, adjust the adjustment screw on the upper platform to make the upper platform move in the vertical direction, and look for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com