Machining method of cylindrical reinforcing cage

A processing method and steel cage technology, applied to wire processing, wire mesh, and other household appliances, can solve the problems of cylindrical steel cages that are easily damaged, many defective products, shorten the service life of cylindrical steel cages, etc., and achieve prolongation The service life and the effect of ensuring the quality of the factory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

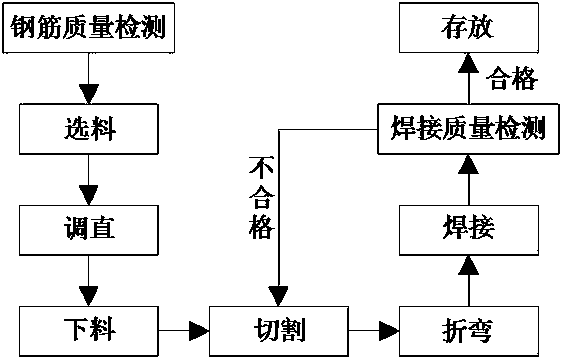

[0036] A method for processing a cylindrical reinforcement cage, comprising the following steps: steel reinforcement quality inspection→material selection→straightening→cutting→cutting→bending→welding→welding quality inspection→storage;

[0037] A steel bar quality inspection: To test various specifications and grades of steel bars, it is necessary to carry a professional steel bar strength testing device to test the steel bars, and then it must have a factory certificate and an entry inspection report before use;

[0038] B material selection: oil stains, floating skin and rust should be removed before the steel bar is processed. The rust removal can be carried out by mechanical derusting, sand blasting, and manual derusting with a wire brush or grinding wheel, and the steel bar should be straight and free of parts For bending, the bent steel bar should be straightened before use;

[0039] C straightening: straightening can be straightened by cold drawing or straightening mac...

Embodiment 2

[0047] In embodiment one, add following operation:

[0048] When straightening in step C, use the cold drawing method to straighten and straighten at a constant speed. The cold drawing rate of grade I steel bars shall not exceed 3%, and the cold drawing rate of class II steel bars shall not exceed 1%. The bending at the end of the main reinforcement cannot Straighten and use a serration-free cut.

[0049] A method for processing a cylindrical reinforcement cage, comprising the following steps: steel reinforcement quality inspection→material selection→straightening→cutting→cutting→bending→welding→welding quality inspection→storage;

[0050] A steel bar quality inspection: To test various specifications and grades of steel bars, it is necessary to carry a professional steel bar strength testing device to test the steel bars, and then it must have a factory certificate and an entry inspection report before use;

[0051] B material selection: oil stains, floating skin and rust sh...

Embodiment 3

[0060] In embodiment two, add following operation:

[0061] When welding in step G, the steel cage skeleton is made in one go. The joints of the main reinforcement of the steel cage should be staggered, and the number of joints on each section should not exceed 50%. The connection is tightly wound, and the stirrups are spot-welded to the main reinforcement, and the main reinforcement is strictly prohibited from being burned.

[0062] A method for processing a cylindrical reinforcement cage, comprising the following steps: steel reinforcement quality inspection→material selection→straightening→cutting→cutting→bending→welding→welding quality inspection→storage;

[0063] A steel bar quality inspection: To test various specifications and grades of steel bars, it is necessary to carry a professional steel bar strength testing device to test the steel bars, and then it must have a factory certificate and an entry inspection report before use;

[0064] B material selection: oil stai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com