A functional metal-organic framework composite material and its preparation method

A technology of metal-organic framework and composite materials, applied in the field of pyrrolidone functionalized metal-organic framework/gold nanoparticle composite materials and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

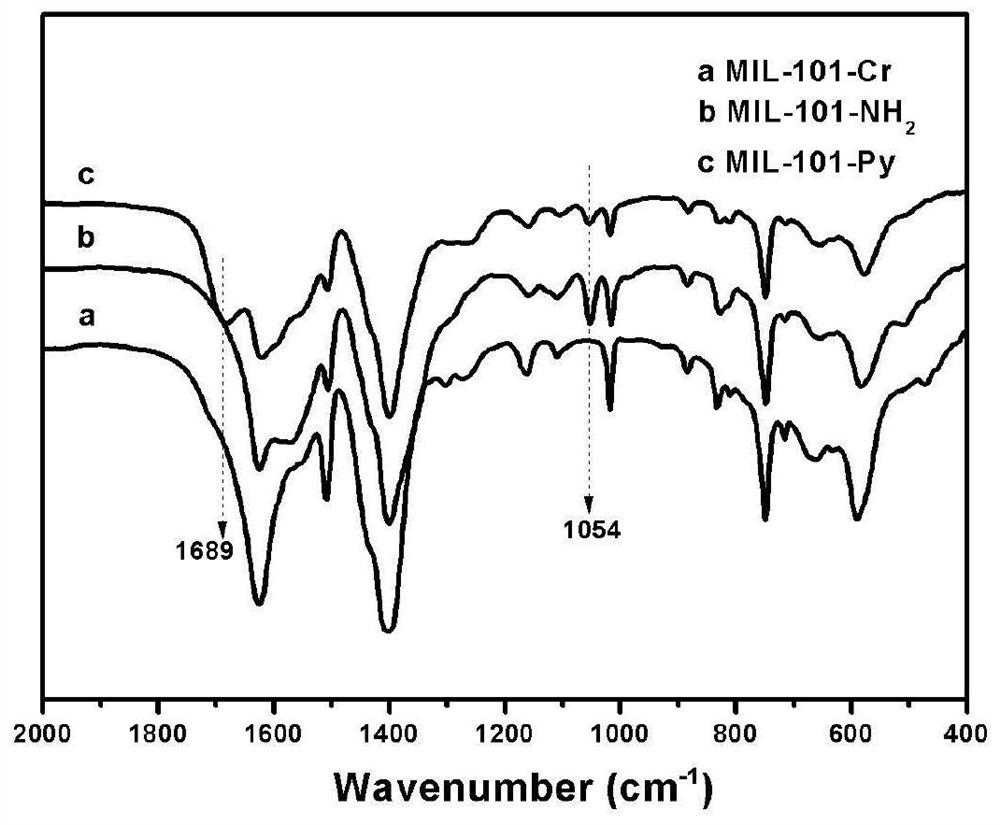

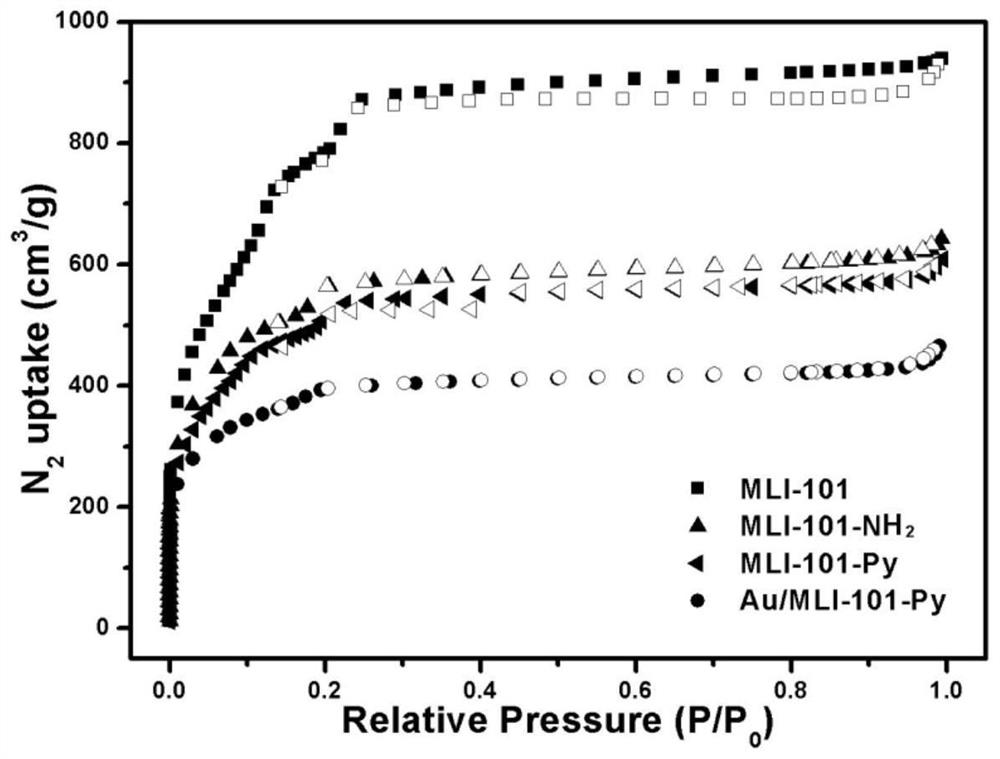

[0032] Step 1: Add 0.001mol chromium nitrate nonahydrate, 0.0015mol terephthalic acid, 0.00075mol hydrofluoric acid and 0.2mol deionized water 1 into the hydrothermal reactor, react at 220°C for 9 hours; cool to room temperature and filter , washed three times with deionized water and absolute ethanol respectively; respectively used 0.5mol deionized water 2 and DMF as solvents, heated and stirred at 50°C for 24 hours; °C for 12 hours in vacuum to obtain MIL-101-Cr containing a chromium open metal center.

[0033] Step 2: At room temperature, disperse 0.001 mol of the MIL-101-Cr in 0.05 mol of anhydrous benzene; add 0.003 mol of ethylenediamine under nitrogen protection and stirring conditions, and react at 60°C for 24 hours; after cooling to room temperature Filter, wash 3 times with benzene, and vacuum dry at 150°C for 12 hours under the condition of vacuum degree of 133Pa to obtain MIL-101-NH with open metal center modified ethylenediamine 2 .

[0034] Step 3: At room temp...

Embodiment 2

[0050] Step 1: Add 0.001mol chromium nitrate nonahydrate, 0.002mol terephthalic acid, 0.0001mol hydrofluoric acid and 0.2mol deionized water 1 into the hydrothermal reactor, react at 200°C for 12 hours; cool to room temperature and filter , washed three times with deionized water and absolute ethanol respectively; respectively used 0.5mol deionized water 2 and DMF as solvents, heated and stirred at 50°C for 24 hours; °C for 12 hours in vacuum to obtain MIL-101-Cr containing a chromium open metal center.

[0051] Step 2: At room temperature, disperse 0.001 mol of the MIL-101-Cr in 0.05 mol of anhydrous benzene; add 0.004 mol of ethylenediamine under nitrogen protection and stirring conditions, and react at 80°C for 20 hours; after cooling to room temperature Filter, wash 3 times with benzene, and vacuum dry at 150°C for 12 hours under the condition of vacuum degree of 133Pa to obtain MIL-101-NH with open metal center modified ethylenediamine 2 .

[0052] Step 3: At room tempe...

Embodiment 3

[0060] Step 1: Add 0.001mol chromium nitrate nonahydrate, 0.002mol terephthalic acid, 0.0001mol hydrofluoric acid and 0.2mol deionized water 1 into the hydrothermal reactor, react at 200°C for 12 hours; cool to room temperature and filter , washed 4 times with deionized water and absolute ethanol respectively; respectively used 0.6mol deionized water 2 and DMF as solvents, heated and stirred at 60°C for 24 hours; °C for 12 hours in vacuum to obtain MIL-101-Cr containing a chromium open metal center.

[0061] Step 2: At room temperature, disperse 0.001 mol of the MIL-101-Cr in 0.05 mol of anhydrous benzene; add 0.004 mol of ethylenediamine under nitrogen protection and stirring conditions, and react at 80°C for 20 hours; after cooling to room temperature Filter, wash 4 times with benzene, and vacuum dry at 120°C for 12 hours under the condition of vacuum degree of 133Pa to obtain MIL-101-NH with open metal center modified ethylenediamine 2 .

[0062] Step 3: At room temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com