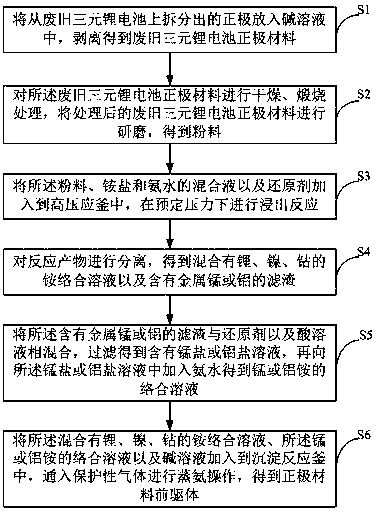

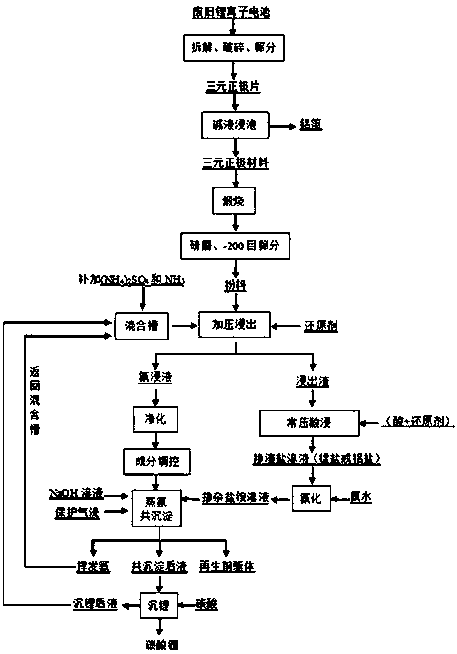

A method for preparing positive electrode material precursor by using waste ternary lithium battery

A ternary lithium battery and cathode material technology, applied in battery recycling, recycling technology, waste collector recycling, etc., can solve the problem of low cathode material recycling efficiency, achieve good industrial application prospects, short-process recycling and reuse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The waste NCM721 (LiNi 0.7 co 0.2 mn 0.1 o 2 ) The ternary lithium battery was placed in a 2 mol / L sodium chloride solution for 36 hours, and the battery was manually disassembled to separate the positive aluminum foil, negative copper foil, shell, diaphragm, and tabs. Put the positive electrode aluminum foil in 1 mol / L sodium hydroxide solution, then peel off the positive electrode material, and wash the peeled positive electrode material with 1 mol / L sodium hydroxide solution. Then put it in a drying oven at 80 °C for 12 h. And put it into a box-type furnace for calcination at 600 °C for 6 hours, cool it to room temperature in the furnace, take it out, put it in a mortar, grind it, and filter it with a 200-mesh sieve to obtain the spent ternary lithium battery cathode material powder. Then weigh 53g of positive electrode material powder and put it into the autoclave, add total ammonium concentration of 8 mol / L, n(NH 3 ) : n(NH 4+ )=2:1 ammonium sulfate and ammon...

Embodiment 2

[0057] The waste NCA ternary lithium battery was placed in 2 mol / L sodium chloride solution for 36 hours, and the battery was manually disassembled to separate the positive aluminum foil, negative copper foil, shell, diaphragm, and tabs. Put the positive electrode aluminum foil in 1 mol / L sodium hydroxide solution, then peel off the positive electrode material, and wash the peeled positive electrode material with 2 mol / L sodium hydroxide solution. Then placed in a drying oven at 90 °C for 12 h. And put it into a box-type furnace for calcination at 600 °C for 6 h, cool it to room temperature in the furnace, take it out, put it into a mortar, grind it, and filter it with a 300-mesh sieve to obtain the positive electrode material powder of the waste ternary lithium battery. Then take 53g of positive electrode material powder and put it into the autoclave, add the total ammonium concentration to be 7.5 mol / L, n(NH 3 ) : n(NH 4+ )=2:1 ammonium sulfate and ammonia water mixed solu...

Embodiment 3

[0060] The waste NCM622 (LiNi 0.6 co 0.2 mn 0.2 o 2 ) The ternary lithium battery was placed in a 2 mol / L sodium chloride solution for 36 hours, and the battery was manually disassembled to separate the positive aluminum foil, negative copper foil, shell, diaphragm, and tabs. Put the positive electrode aluminum foil in 1 mol / L sodium hydroxide solution, then peel off the positive electrode material, and wash the peeled positive electrode material with 1 mol / L sodium hydroxide solution. Then put it in a drying oven at 80 °C for 12 h. And put it into a box-type furnace for calcination at 700 °C for 2 hours, cool it to room temperature in the furnace, take it out, put it into a mortar, grind it, and filter it with a 500-mesh sieve to obtain the positive electrode material powder of the waste ternary lithium battery. Then take 100g of positive electrode material powder and put it into the autoclave, add the total ammonium concentration of 12 mol / L, n(NH 3 ) : n(NH 4+ ) = 1.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com