Experimental device and method for measuring dust explosion characteristics under visual isobaric condition

An experimental device and dust technology, applied in the direction of material explosion, can solve the problems of confined space, small size, inability to observe dust accurately and clearly, and achieve the effect of eliminating impact, improving safety and reducing impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

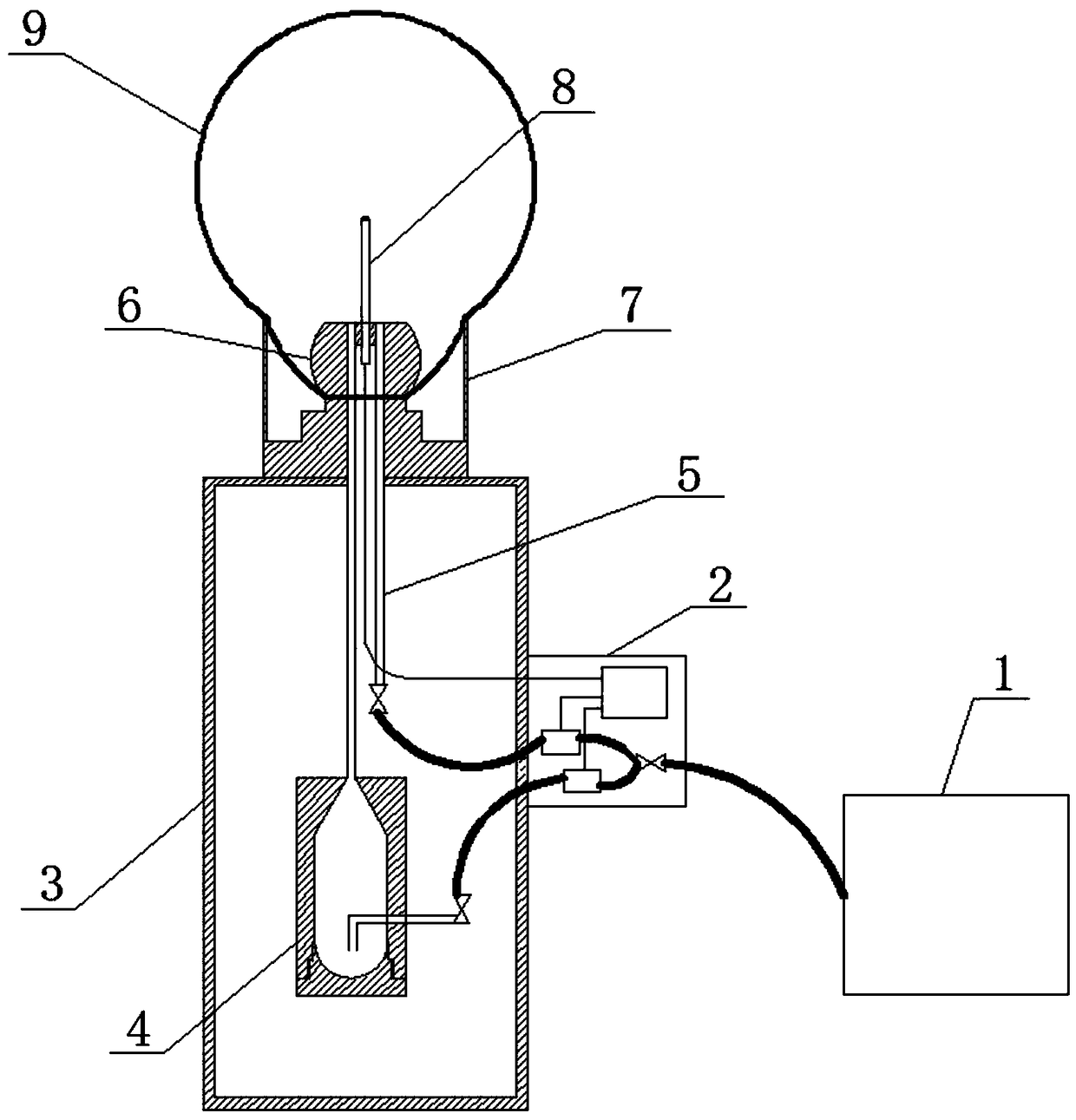

[0027] An experimental device for measuring dust explosion characteristics under visual isobaric conditions such as figure 1 As shown, the gas distribution system 1 is composed of one or more combined gas systems of air, combustible gas and inert gas, and is equipped with a corresponding pressure reducing valve, which can control the pressure of gas delivery; intelligent control system 2, It is fixedly installed on the right side of the bracket 3 of the powder spraying device. It is used as the control center of the entire gas distribution entry and output, and the time of gas distribution entry and dust spraying is controlled by setting the program; the powder storage tank 4 is a detachable metal composite tank. A high-pressure gas inlet hole is provided near the bottom end of one side, and the powder spraying gas pipe extends into the middle of the powder storage tank through the hole, and the dust dispersing injection hole on the upper part is fixedly connected to the nozzle...

Embodiment 2

[0029] In this example, hydrogen-air mixed gas is used for gas distribution, and aluminum powder is used for dust, so as to illustrate the operation steps of an experimental method for measuring the combustion and explosion characteristics of dust under visual isobaric conditions:

[0030] St1: When conducting experiments, first write the operating program of the intelligent control system 2, and set the time for air intake, powder spraying and ignition;

[0031] St2: Configure a hydrogen-air mixed gas with a certain volume ratio (1:9), adjust the pressure reducing valve of the gas distribution system 1, so that the output pressure of the mixed gas reaches the requirement (2MPa);

[0032] St3: Weigh a certain mass (10g) of aluminum powder and place it in the powder storage tank 4;

[0033] St4: fix the transparent latex balloon 9 on the nozzle 6;

[0034] St5: remote start, turn on and control the intelligent control system 2, so that it can gradually control the ventilation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com