Multi-beam coaxial laser damage threshold test device and realization method

A technology of laser damage threshold and testing device, which is used in measurement devices, optical instrument testing, testing optical performance, etc., can solve the problem of difficulty in ensuring multi-beam collimation and the same beam waist position, increasing equipment and testing costs, and optical component dispersion. and other problems, to achieve the effect of wide measurement object range, high sensitivity and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

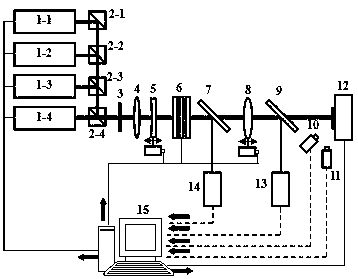

[0032] A multi-optical coaxial laser damage threshold testing device, the output wavelengths are λ 1 , lambda 2 , lambda 3 and lambda 4 The four high-energy pulsed lasers 1-1, laser 2 1-2, laser 3 1-3 and laser 4 1-4, the four laser beams pass through cube prism 1 2-1, cube prism 2 2-2, and cube prism Three 2-3 and four cubic prisms 2-4 reflect (or transmit) and enter the same optical axis system, and pass through the switch baffle plate 3 on the main optical path in turn, and enter the positive lens 4 and negative lens 5 of the variable-pitch beam expander system , an attenuator 6, a first beam splitter 7, a displacement focusing lens 8, a second beam splitter 9, a sample stage 12, a CCD camera 10, a fiber optic spectrometer 11, a beam analyzer 13 and an energy meter 14.

[0033] The output wavelengths of the four high-energy pulsed lasers are 1064 nm, 532 nm, 355 nm and 266 nm respectively, the pulse width is 10 ns, the output laser beam spot is a Gaussian spot with a dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com