Insert, engine cylinder head and engine

A technology for engine cylinders and engines, which is applied in the direction of engine components, machines/engines, cylinders, etc., can solve the problems of low engine efficiency, large difference in thermal expansion coefficient, increased engine noise, etc., to solve the problem of louder sound and simple forming Convenience and high cylinder head strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

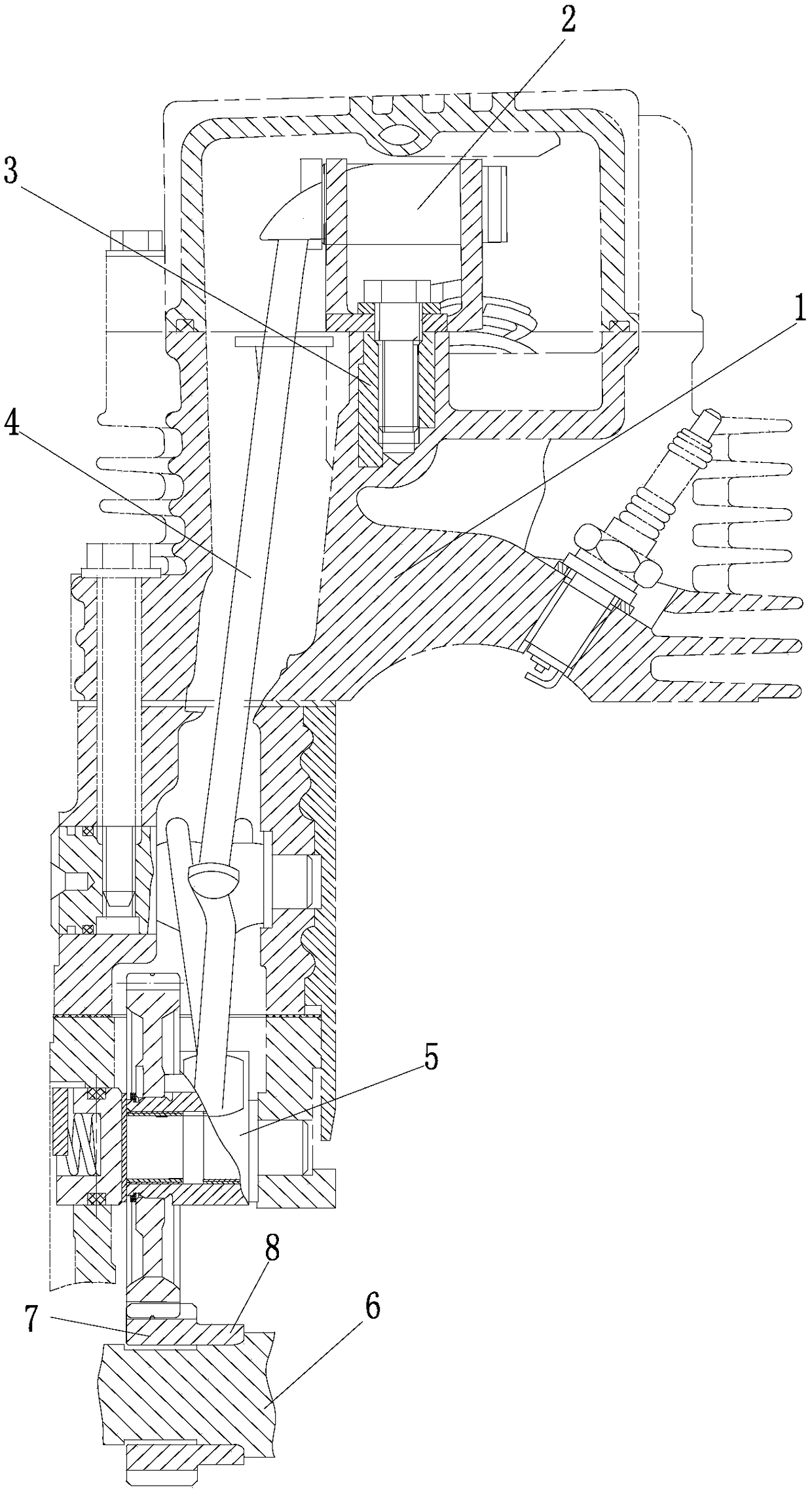

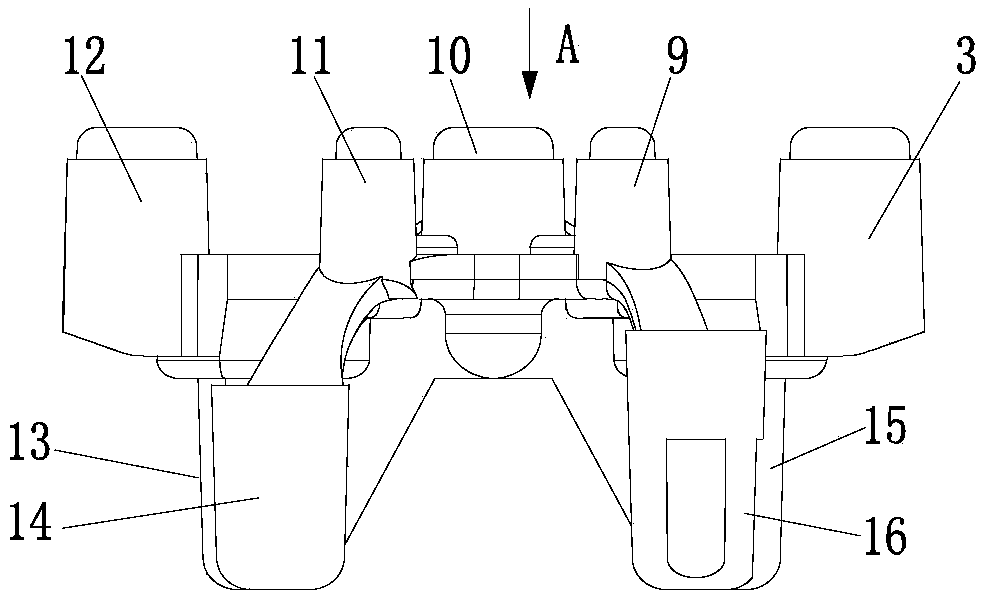

[0021] As shown in the figure: the insert of this embodiment, the insert includes a steel or cast iron insert I for being embedded in the engine cylinder head, and the steel or cast iron insert I forms a rocker supporting the engine gas distribution system The support part where the arm bracket is installed; the steel or cast iron insert Ⅰ and the components of the gas distribution system (such as the rocker arm, etc.) are made of steel (cast iron) with similar thermal expansion coefficients. When the engine temperature rises, each gas distribution system The deformation of the parts is equivalent, and the valve clearance is always guaranteed to be unchanged or changed slightly between the hot and cold engines, so it can effectively solve the problem of louder engine sound caused by the valve clearance of the hot and cold engines.

[0022] In this embodiment, a steel or cast iron insert II for being embedded in the cylinder head of the engine is also included, and the steel or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com