Semi-open impeller pump with sealing cover plate structure

A sealed cover, semi-open technology, applied in the field of water pumps, can solve the problems of increasing the manufacturing difficulty, cost and manufacturing time of the pump casing, increasing the difficulty of producing impeller blades, and improving the manufacturing process requirements, and achieves good passability and cost. Low, simple and convenient forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

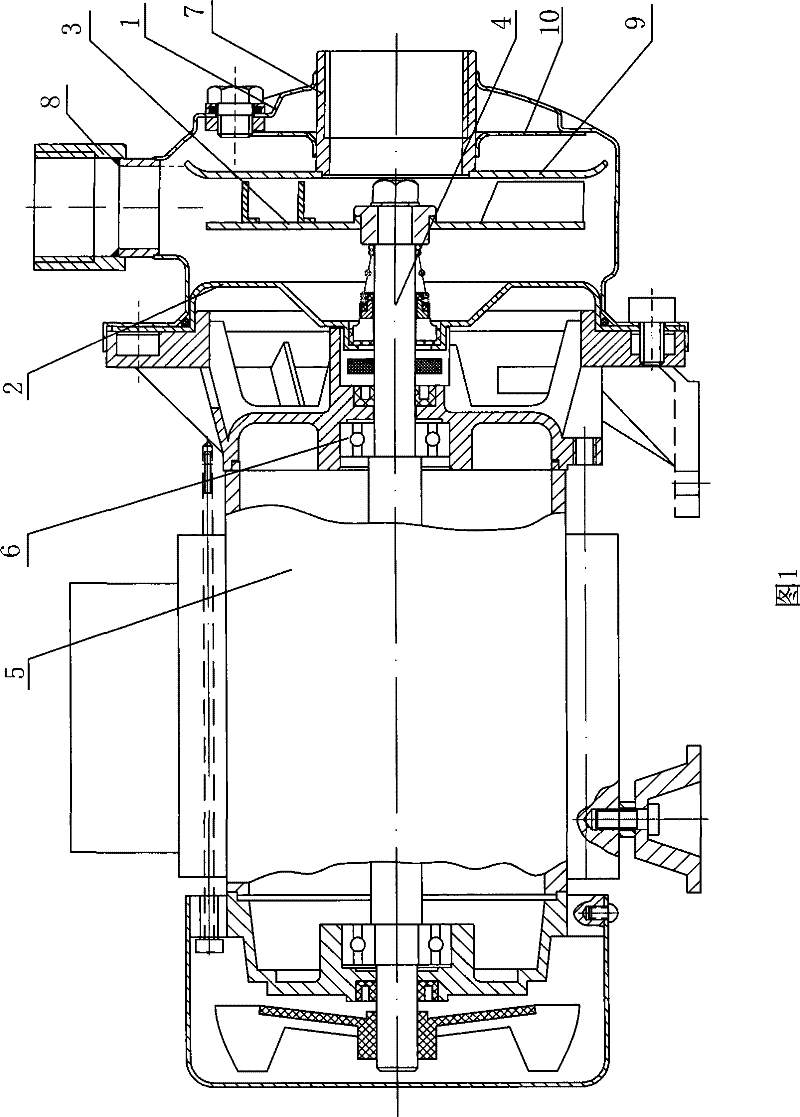

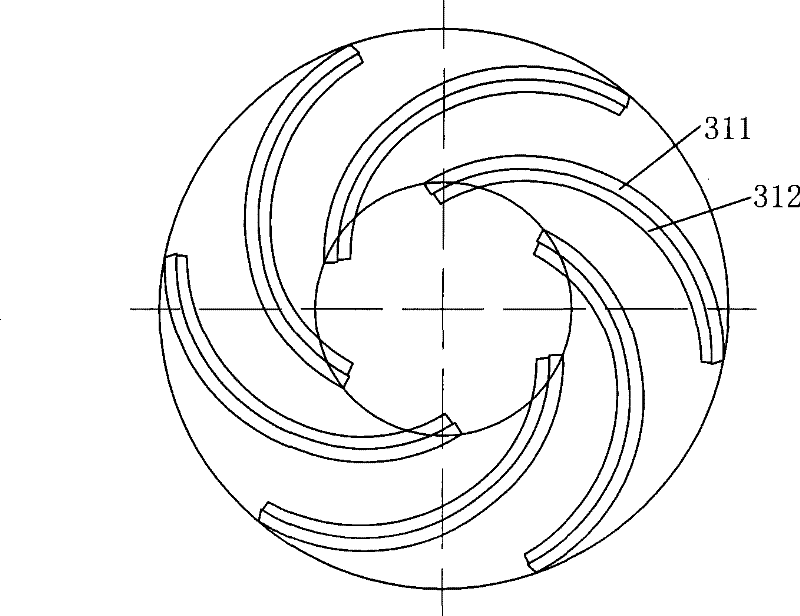

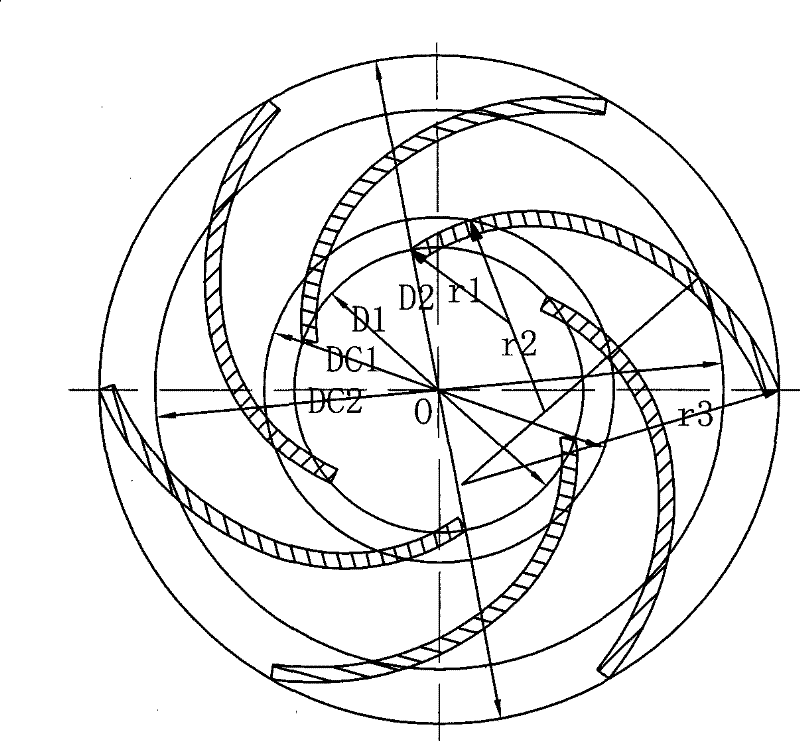

[0027] like Figure 1 to Figure 6 As shown, the semi-open impeller pump with a sealing cover plate structure of the present invention is composed of a pump casing 1, a pump back cover 2 installed in the pump casing, an impeller 3, a pump shaft 4, and a motor 5 arranged outside the pump casing 1. , wherein, the pump casing 1, the impeller 3 and the pump back cover 2 are formed by stamping and welding, and the impeller 3 is located in the space where the pump casing 1 and the pump back cover 2 are sealed, installed on the pump shaft 4, and driven by the motor 5 Rotate; the motor 5 is fixed on the pump casing 1 by means of a connecting frame 6, the pump casing 1 is provided with an inlet pipe 7 and an outlet pipe 8, and the impeller 3 is a semi-open structure, composed of blades 31, hub 32 Composed of the rear cover plate 33, the inlet pipe 7 extends from the outside of the pump casing to the inside of the pump casing, the rear end of the inlet pipe 7 is located at the front end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com