Stamped and welded semi-open impeller centrifugal pump

A stamping and welding, semi-open technology, applied in the field of stamping and welding semi-open impeller centrifugal pumps, can solve the problems of increasing the difficulty of manufacturing the pump casing, the cost and the manufacturing time, increasing the difficulty of producing the impeller blades, and the high requirement of the strength of the pump casing. , to achieve the effect of good passability, good strength and rigidity, and easy flow path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

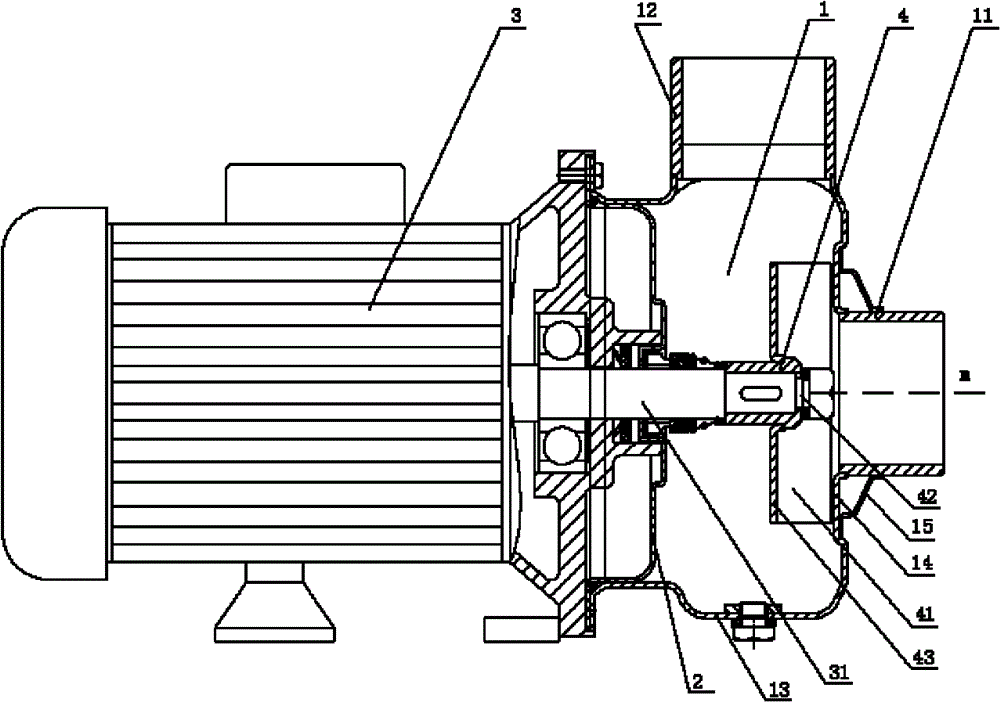

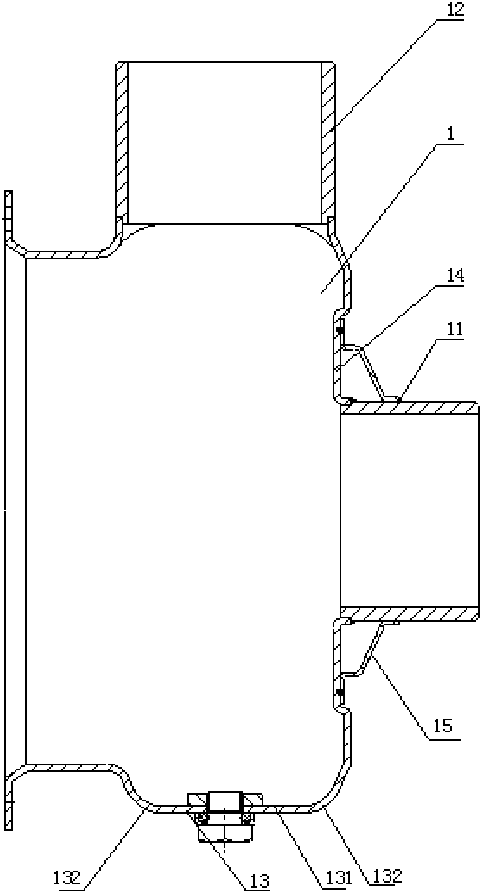

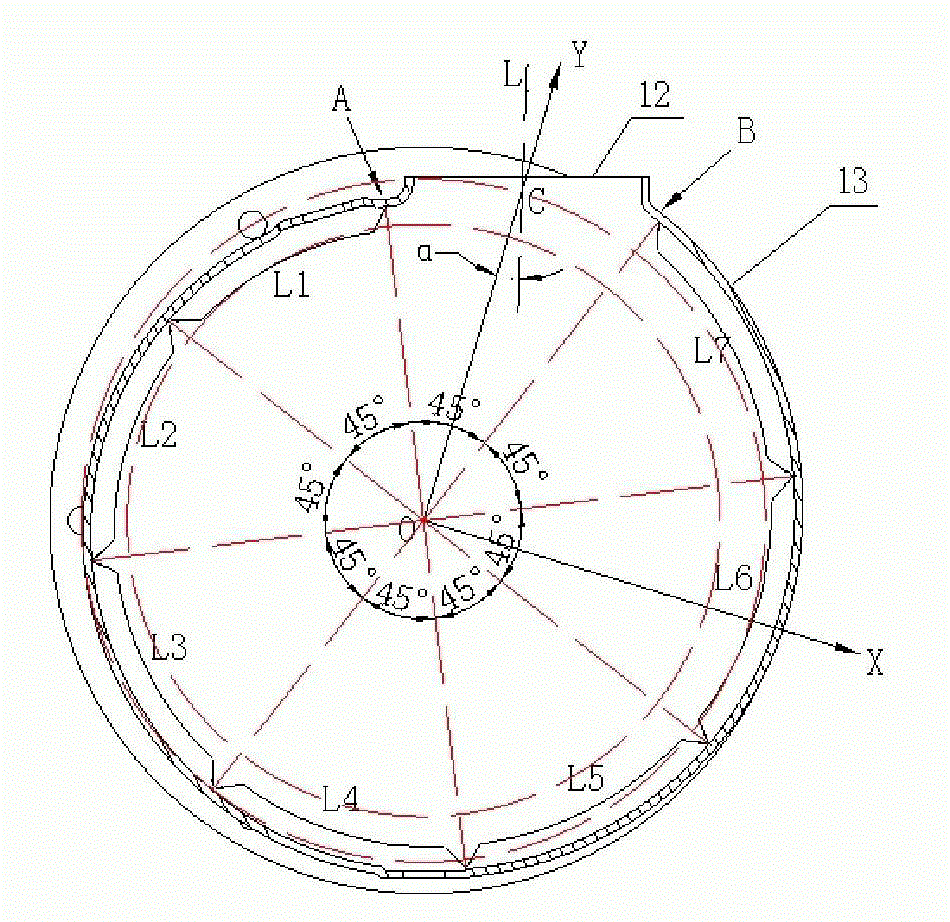

[0027] Such as Figure 1 to Figure 3 As shown, the stamping and welding semi-open impeller centrifugal pump of the present invention includes a pump body 1, a pump back cover 2, a motor 3 installed at the open end of the pump body, and an impeller 4 arranged in the pump body 1. The impeller 4 is installed The pump shaft 31 is driven to rotate by a motor 3. The pump body 1 is provided with a water inlet pipe 11 and a water outlet pipe 12. The water inlet pipe 11 and the pump shaft 31 are coaxially mounted on the outer side of the axial surface 13 of the pump body. The impeller 4 is a semi-open structure and is composed of blades 41, a hub 42 and a rear cover 43. The front end surface of the blade 41 and the axial surface 14 of the pump body close to the front end surface are respectively perpendicular to the axial direction of the pump body. The distance between the front end face of the blade 41 and the axial face of the pump body is not more than 2 mm, forming an end face seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com