Fire-proof safe with alarm function

A safe and functional technology, applied in the safe field, can solve the problem of the safe entering the fire in the cabinet, without any countermeasures, and failing to protect the cabinet. The effect of suitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

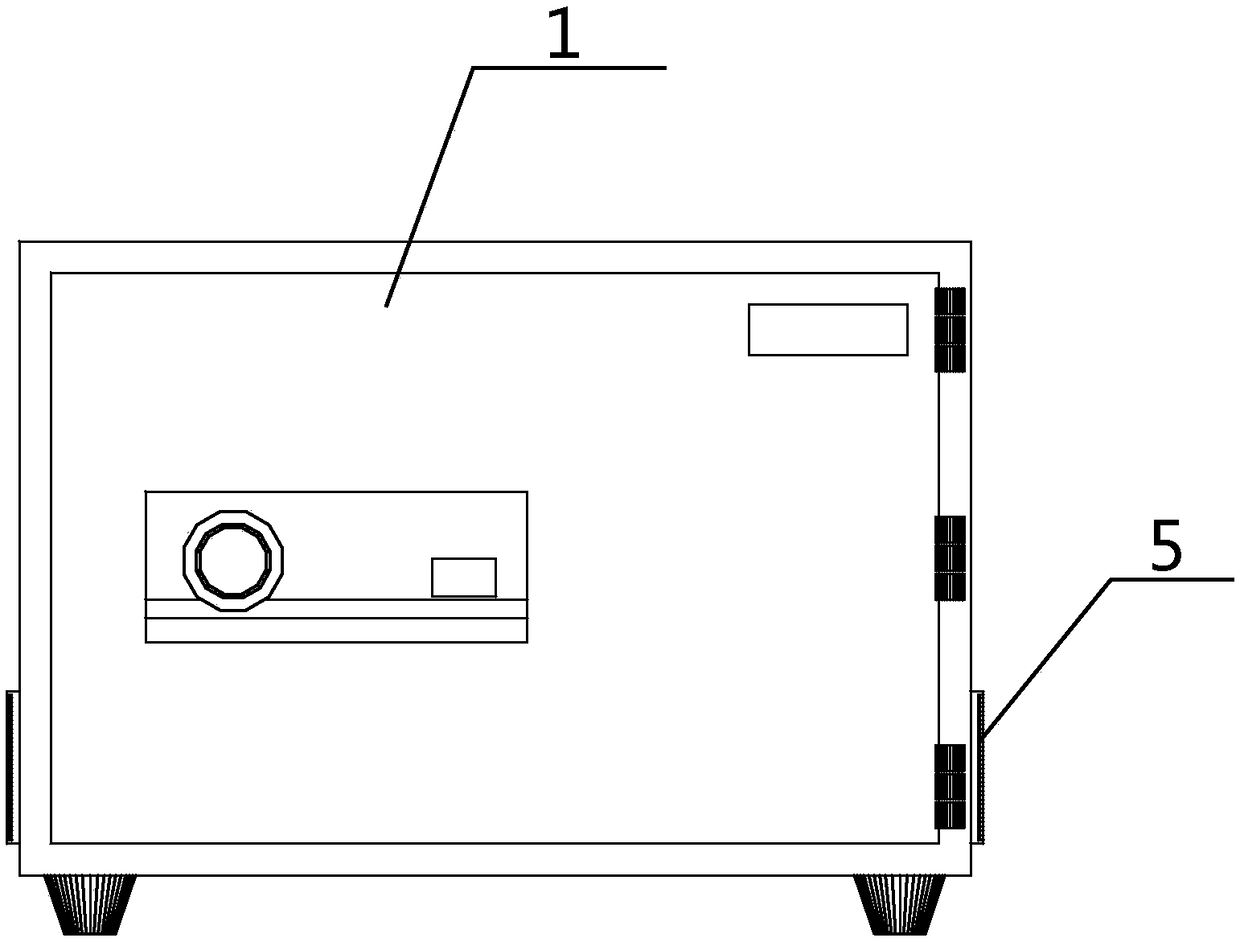

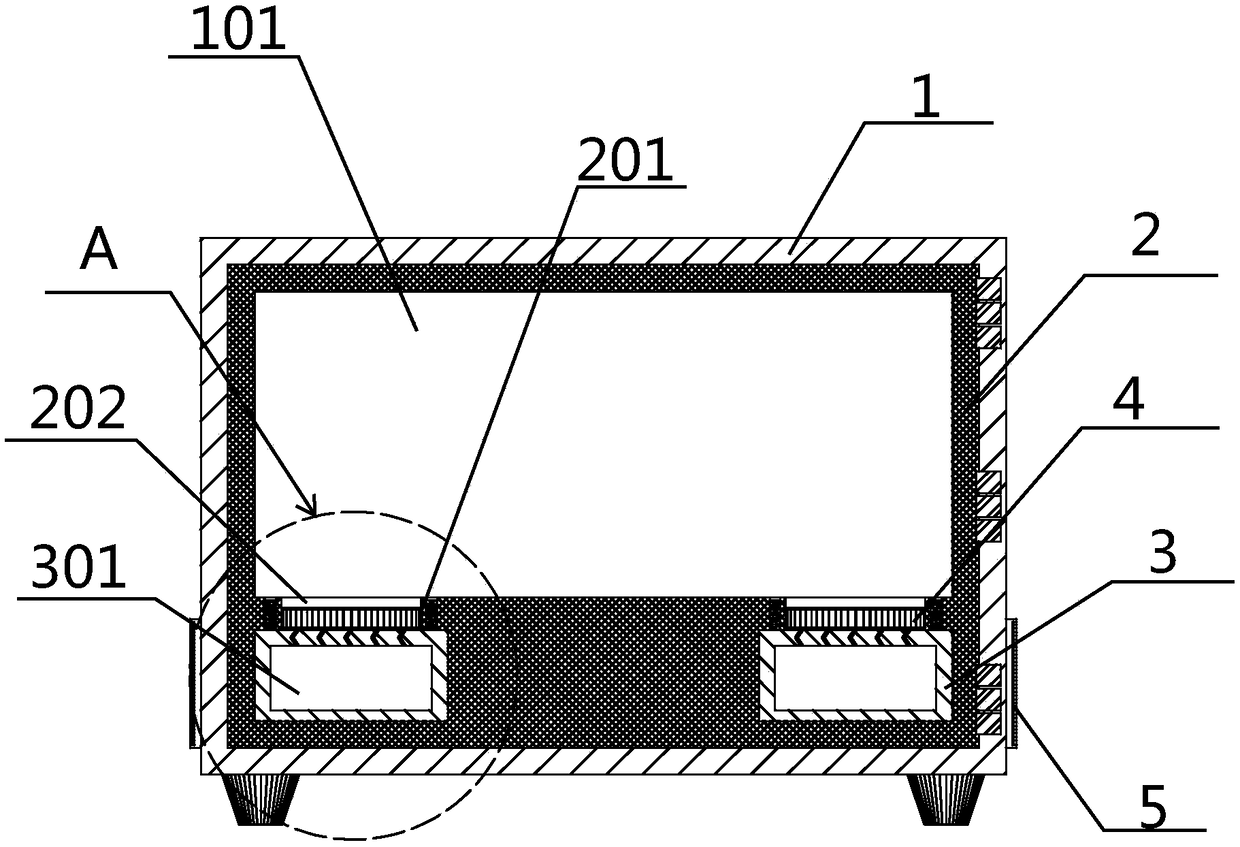

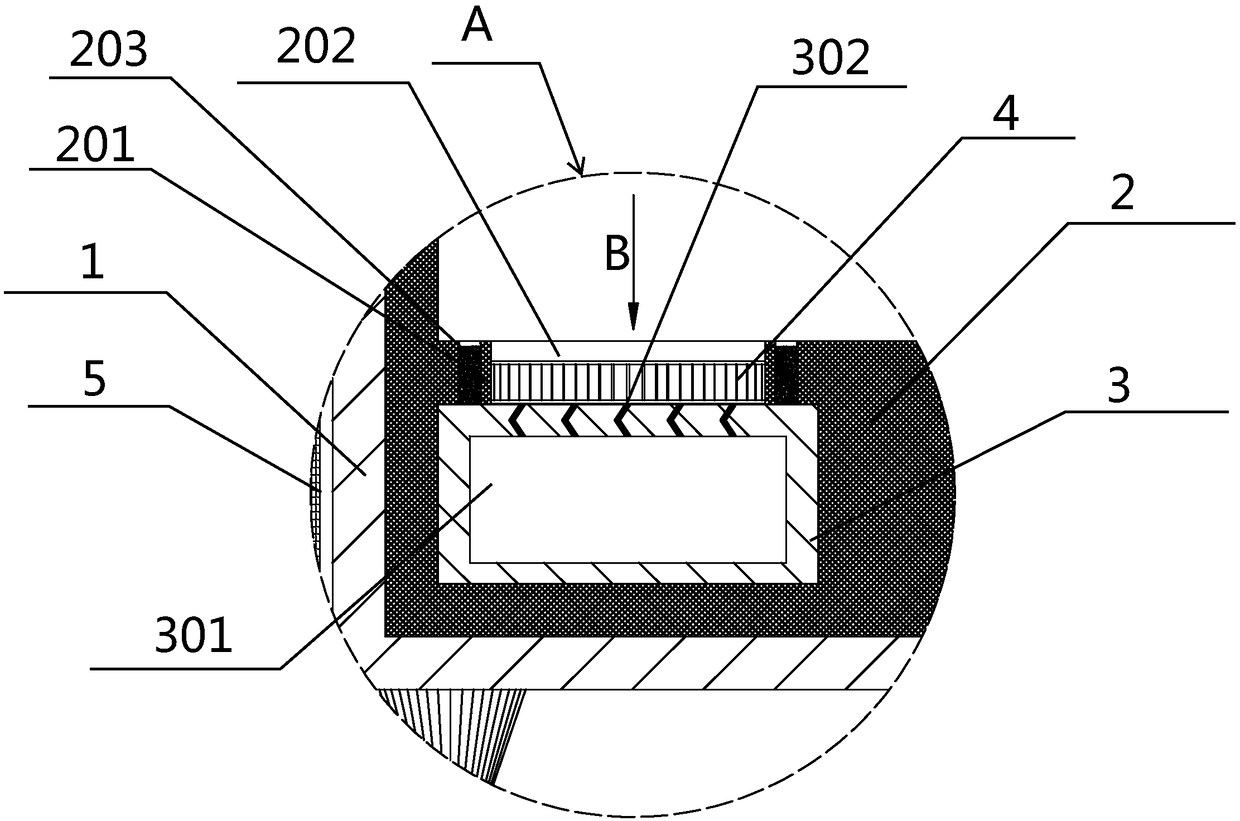

[0038] Such as figure 1 and figure 2 A fireproof safe with an alarm function is shown, including a main body 1 and a lining 2, the main body 1 includes a cabinet door, a cabinet body, a safety lock and cabinet feet, and an alarm device 5 is provided outside the main body 1, and the alarm device 5 is The buzzer, the inner lining 2 is arranged inside the main body 1 and is attached to the cabinet body to form an inner cavity 101. The inner cavity 101 is used to store items, and there are two inner linings 2 on the bottom part of the cabinet body. The liquid storage chamber 3, the liquid storage chamber 3 is made of high-strength calcium silicate heat insulation material with high compressive strength, flexural strength and good heat insulation performance, the liquid storage chamber 3 is a hollow structure, forming a liquid storage chamber 301, There is liquid carbon dioxide with a maximum capacity of about 4 / 5 in the liquid storage chamber 301, such as image 3 As shown, the...

Embodiment 2

[0040] Such as figure 1 and figure 2 A fireproof safe with an alarm function is shown, including a main body 1 and a lining 2, the main body 1 includes a cabinet door, a cabinet body, a safety lock and cabinet feet, and an alarm device 5 is provided outside the main body 1, and the alarm device 5 is The buzzer, the inner lining 2 is arranged inside the main body 1 and is attached to the cabinet body to form an inner cavity 101. The inner cavity 101 is used to store items, and there are two inner linings 2 on the bottom part of the cabinet body. The liquid storage chamber 3, the liquid storage chamber 3 is made of high-strength calcium silicate heat insulation material with high compressive strength, flexural strength and good heat insulation performance, the liquid storage chamber 3 is a hollow structure, forming a liquid storage chamber 301, There is liquid carbon dioxide with a maximum capacity of about 3 / 4 in the liquid storage chamber 301, such as image 3 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com