A kind of polyimide fiber far-infrared emission paper and preparation method thereof

A polyimide fiber, far-infrared emission technology, applied in special paper, fiber raw material processing, papermaking, etc., can solve the problems of carbon nanotube paper, such as large brittleness, hindering preparation, easy to break, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The invention provides a kind of preparation method of polyimide fiber far-infrared emission paper, comprising the following steps:

[0020] mixing polyimide fiber slurry, carbon nanotube dispersion, polyacrylate and cationic polyacrylamide to obtain a mixed slurry;

[0021] The mixed slurry is coated on one side of the substrate, cured, and a solidified layer is formed on one side of the substrate; the substrate is peeled off, and the obtained solidified layer is subjected to thermocompression molding to obtain polyimide fiber far-infrared emitting paper.

[0022] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0023] The invention mixes polyimide fiber slurry, carbon nanotube dispersion liquid, polyacrylate and cationic polyacrylamide to obtain mixed slurry. In the present invention, the polyimide fiber slurry preferably includes polyimide fibers, a debondi...

Embodiment 1

[0048] 3g polyimide chopped fibers are mixed with 300g ethanol, then mixed with 0.03g polyethylene oxide (PEO), beaten to obtain polyimide fiber slurry;

[0049] Mix 3g of carbon nanotubes with 300g of ethanol, then mix with 0.02PVP, ultrasonicate for 20min, and shear for 30min to obtain a carbon nanotube dispersion;

[0050] Mix the polyimide fiber slurry and the carbon nanotube dispersion evenly, and grind to obtain the mixed slurry;

[0051] Mix the mixed slurry, 0.02g polyacrylate and 0.01g cationic polyacrylamide to obtain slurry;

[0052] With the cellulose film as the base, use a high-pressure airless sprayer to spray the slurry evenly onto the base under the condition of 0.2 MPa, dry it in a drying oven, peel off the base, and use a flat vulcanizer to dry it at 200 The polyimide far-infrared emitting paper was obtained by hot pressing for 3 minutes under the conditions of ℃ and 13 MPa.

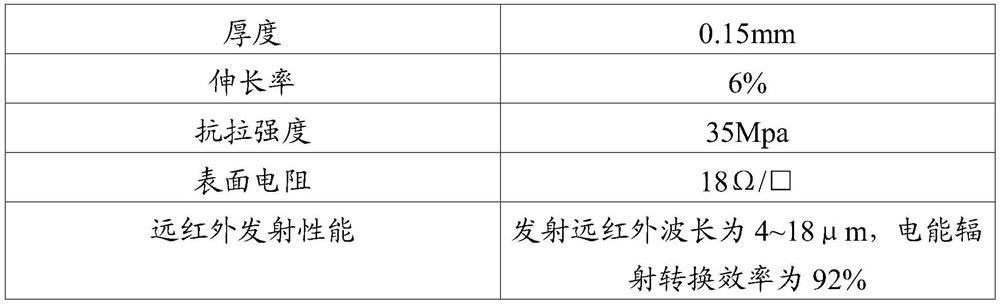

[0053] Described polyimide far-infrared emission paper is carried out the test o...

Embodiment 2

[0057] 3g polyimide chopped fibers are mixed with 400g ethanol, then mixed with 0.035g polyethylene oxide (PEO), beaten to obtain polyimide fiber slurry;

[0058] Mix 2g of carbon nanotubes with 250g of ethanol, then mix with 0.02g of SDS, sonicate for 20 minutes, and shear for 40 minutes to obtain a carbon nanotube dispersion;

[0059] Mix the polyimide fiber slurry and the carbon nanotube dispersion evenly, and grind to obtain the mixed slurry;

[0060] Mix the mixed slurry, 0.02g polyacrylate and 0.01g cationic polyacrylamide to obtain slurry;

[0061] With the cellulose film as the substrate, use a high-pressure airless sprayer to spray the slurry evenly on the substrate under the condition of 0.4MPa, dry it in an oven, peel off the substrate, and use a flat vulcanizer to dry the substrate at 250 The polyimide far-infrared emitting paper was obtained by hot pressing for 4 minutes under the conditions of ℃ and 14 MPa.

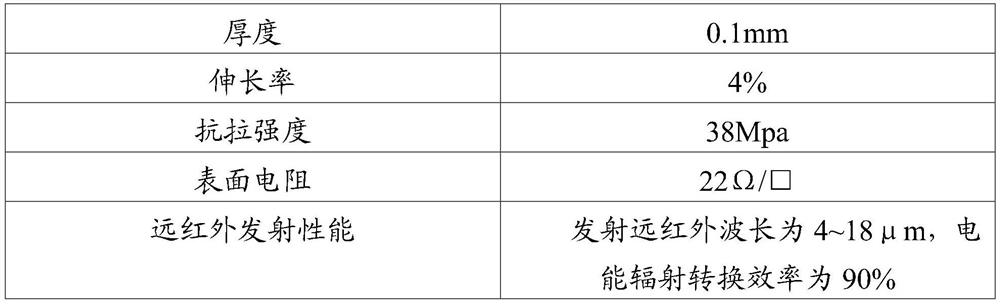

[0062] Described polyimide far-infrared emission pap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com