Polyimide fiber far infrared emission paper and preparation method thereof

A polyimide fiber and far-infrared emission technology, which is applied in special paper, fiber raw material processing, paper, etc., can solve the problem of far-infrared emission paper for undiscovered carbon nanotubes, large brittleness and easy breakage of carbon nanotube paper, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The invention provides a kind of preparation method of polyimide fiber far-infrared emission paper, comprising the following steps:

[0020] mixing polyimide fiber slurry, carbon nanotube dispersion, polyacrylate and cationic polyacrylamide to obtain a mixed slurry;

[0021] The mixed slurry is coated on one side of the substrate, cured, and a solidified layer is formed on one side of the substrate; the substrate is peeled off, and the obtained solidified layer is subjected to thermocompression molding to obtain polyimide fiber far-infrared emitting paper.

[0022] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0023] The invention mixes polyimide fiber slurry, carbon nanotube dispersion liquid, polyacrylate and cationic polyacrylamide to obtain mixed slurry. In the present invention, the polyimide fiber slurry preferably includes polyimide fibers, a debondi...

Embodiment 1

[0048] 3g polyimide chopped fibers are mixed with 300g ethanol, then mixed with 0.03g polyethylene oxide (PEO), beaten to obtain polyimide fiber slurry;

[0049] Mix 3g of carbon nanotubes with 300g of ethanol, then mix with 0.02PVP, ultrasonicate for 20min, and shear for 30min to obtain a carbon nanotube dispersion;

[0050] Mix the polyimide fiber slurry and the carbon nanotube dispersion evenly, and grind to obtain the mixed slurry;

[0051] Mix the mixed slurry, 0.02g polyacrylate and 0.01g cationic polyacrylamide to obtain slurry;

[0052] With the cellulose film as the base, use a high-pressure airless sprayer to spray the slurry evenly onto the base under the condition of 0.2 MPa, dry it in a drying oven, peel off the base, and use a flat vulcanizer to dry it at 200 The polyimide far-infrared emitting paper was obtained by hot pressing for 3 minutes under the conditions of ℃ and 13 MPa.

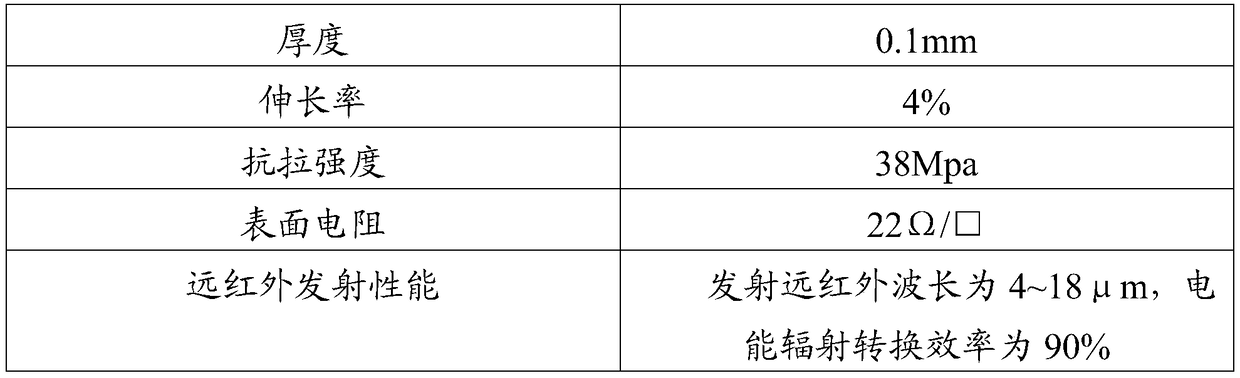

[0053] Described polyimide far-infrared emission paper is carried out the test o...

Embodiment 2

[0057] 3g polyimide chopped fibers are mixed with 400g ethanol, then mixed with 0.035g polyethylene oxide (PEO), beaten to obtain polyimide fiber slurry;

[0058] Mix 2g of carbon nanotubes with 250g of ethanol, then mix with 0.02g of SDS, sonicate for 20 minutes, and shear for 40 minutes to obtain a carbon nanotube dispersion;

[0059] Mix the polyimide fiber slurry and the carbon nanotube dispersion evenly, and grind to obtain the mixed slurry;

[0060] Mix the mixed slurry, 0.02g polyacrylate and 0.01g cationic polyacrylamide to obtain slurry;

[0061] With the cellulose film as the substrate, use a high-pressure airless sprayer to spray the slurry evenly on the substrate under the condition of 0.4MPa, dry it in an oven, peel off the substrate, and use a flat vulcanizer to dry the substrate at 250 The polyimide far-infrared emitting paper was obtained by hot pressing for 4 minutes under the conditions of ℃ and 14 MPa.

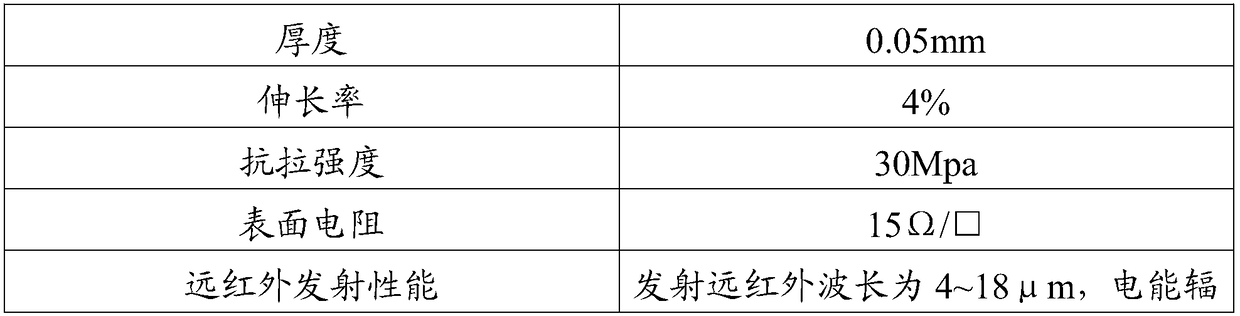

[0062] Described polyimide far-infrared emission pap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com