Method for producing thermal-insulation and formaldehyde-adsorption wallpaper by using spunlaced nonwoven base cloth

A technology for thermal insulation and adsorption of formaldehyde, applied in textiles and papermaking, fabric surface trimming, heating/cooling fabrics, etc., can solve health hazards and other problems, and achieve the effect of improving surface smoothness and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

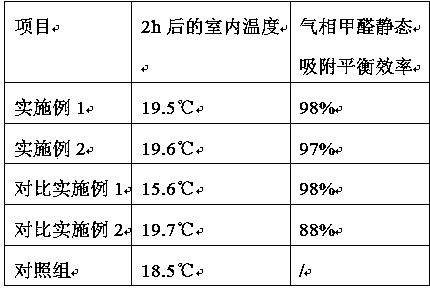

Examples

Embodiment 1

[0025] A method for preparing heat-insulating and heat-insulating formaldehyde-absorbable wallpaper with a hydroentangled nonwoven base cloth, characterized in that it comprises the following steps:

[0026] (1) Pretreatment of spunlace nonwoven base fabric:

[0027] Pre-setting: Place the spunlace nonwoven base fabric vertically parallel to the card clothing of the needle-plate heat-setting machine, pre-setting at 180-185°C for 40 seconds, take it out, and cool it down to room temperature naturally;

[0028] Calendering finishing: calender the spunlace nonwoven base fabric after pre-setting treatment on a flat vulcanizing machine, and calender it for 50s at a pressure of 10MPa and a temperature of 60-65°C, take it out, and cool it naturally;

[0029] (2) Coating and calendering finishing process of spunlace nonwoven base fabric:

[0030] Add 0.1 part of dispersant to the water and stir at low speed for 2 minutes, add 50 parts of heavy calcium carbonate and stir at high speed...

Embodiment 2

[0038] A method for preparing heat-insulating and heat-insulating formaldehyde-absorbable wallpaper with a hydroentangled nonwoven base cloth, characterized in that it comprises the following steps:

[0039] (1) Pretreatment of spunlace nonwoven base fabric:

[0040] Pre-setting: Place the spunlace nonwoven base fabric vertically parallel to the card clothing of the needle plate heat setting machine, pre-setting at 180-185°C for 50s, take it out, and cool it down to room temperature naturally;

[0041] Calendering finishing: calender the spunlace nonwoven base fabric after pre-setting treatment on a flat vulcanizing machine, press it for 60s at a pressure of 10MPa and a temperature of 60-65°C, take it out, and cool it naturally;

[0042] (2) Coating and calendering finishing process of spunlace nonwoven base fabric:

[0043] Add 0.2 parts of dispersant to the water and stir at low speed for 5 minutes, add 60 parts of heavy calcium carbonate and stir at high speed, drop ammonia ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com