Nano diamond superheavy gear oil and preparation method thereof

A nano-diamond and gear oil technology, applied in the field of lubricating oil, can solve the problems of easy burns and gluing, insufficient protection of gearboxes, and inability to form tooth surfaces, so as to improve extreme pressure, anti-wear performance, anti-oxidation performance, and good heat. Effect with oxidative stability, best filtration and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

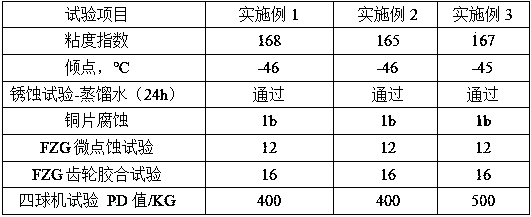

Embodiment 1

[0024] A nano-diamond super-heavy-duty gear oil, consisting of the following components in parts by weight: 28 parts of metallocene PAO150 base oil, 20 parts of cyclohexanedicarboxylate, 18 parts of alkylnaphthalene, and nano-diamond modified by lipophilic surface 0.01 parts of fine particles, 0.5 parts of aromatic amine antioxidant, 1 part of viscosity index improver, 1.4 parts of ashless composite extreme pressure anti-wear agent, 1.0 part of repairing friction modifier, 0.8 part of anti-emulsifier, 1.2 parts of anti-rust and anti-corrosion agent share;

[0025] Among them, the particle size of nano-diamond particles is below 5nm, and the particle size is uniform;

[0026] Wherein, aromatic amine antioxidant is dialkyl diphenylamine;

[0027] Wherein, the viscosity index improver is polyalkylmethacrylate;

[0028] Among them, the ashless composite extreme pressure antiwear agent is a mixture of tricresyl phosphate (T306) and aryl phosphate;

[0029] Among them, the repair...

Embodiment 2

[0037] A nano-diamond super-heavy-duty gear oil, consisting of the following components in parts by weight: 32 parts of metallocene PAO150 base oil, 24 parts of cyclohexanedicarboxylate, 22 parts of alkylnaphthalene, and nano-diamond modified by lipophilic surface 0.02 parts of particles, 1.1 parts of aromatic amine antioxidant, 1.3 parts of viscosity index improver, 2.0 parts of ashless composite extreme pressure anti-wear agent, 1.3 parts of repairing friction modifier, 1.1 parts of anti-emulsifier, 1.5 parts of anti-rust and anti-corrosion agent share;

[0038] Among them, the particle size of nano-diamond particles is below 5nm, and the particle size is uniform;

[0039] Wherein, the aromatic amine antioxidant is N-phenyl-α-aniline;

[0040] Wherein, the viscosity index improver is polyalkylmethacrylate;

[0041] Among them, the ashless composite extreme pressure antiwear agent is a mixture of tricresyl phosphate (T306), aryl phosphate, and alkyl polysulfide;

[0042] A...

Embodiment 3

[0050] A nano-diamond super-heavy-duty gear oil, consisting of the following components in parts by weight: 35 parts of metallocene PAO150 base oil, 27 parts of cyclohexanedicarboxylate, 25 parts of alkylnaphthalene, and nano-diamond modified by lipophilic surface 0.03 parts of microparticles, 1.6 parts of aromatic amine antioxidant, 1.6 parts of viscosity index improver, 2.6 parts of ashless composite extreme pressure antiwear agent, 1.6 parts of repairing friction modifier, 1.3 parts of anti-emulsifier, 1.7 parts of anti-rust and anti-corrosion agent share;

[0051] Among them, the particle size of nano-diamond particles is below 5nm, and the particle size is uniform;

[0052] Wherein, the aromatic amine antioxidant is dialkyl diphenylamine or N-phenyl-α-aniline or a mixture of the two;

[0053] Wherein, the viscosity index improver is polyalkylmethacrylate;

[0054] Among them, the ashless composite extreme pressure antiwear agent is a mixture of two or three of tricresyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com