A kind of functionalized nano cellulose hydrogel and preparation method thereof

A technology of nanocellulose and oxidized cellulose, applied in prosthesis, medical science, etc., can solve the problems of inability of cells to grow and migrate, harsh conditions, unfavorable cell mixing, etc., and achieve good biocompatibility, high water content, biological good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

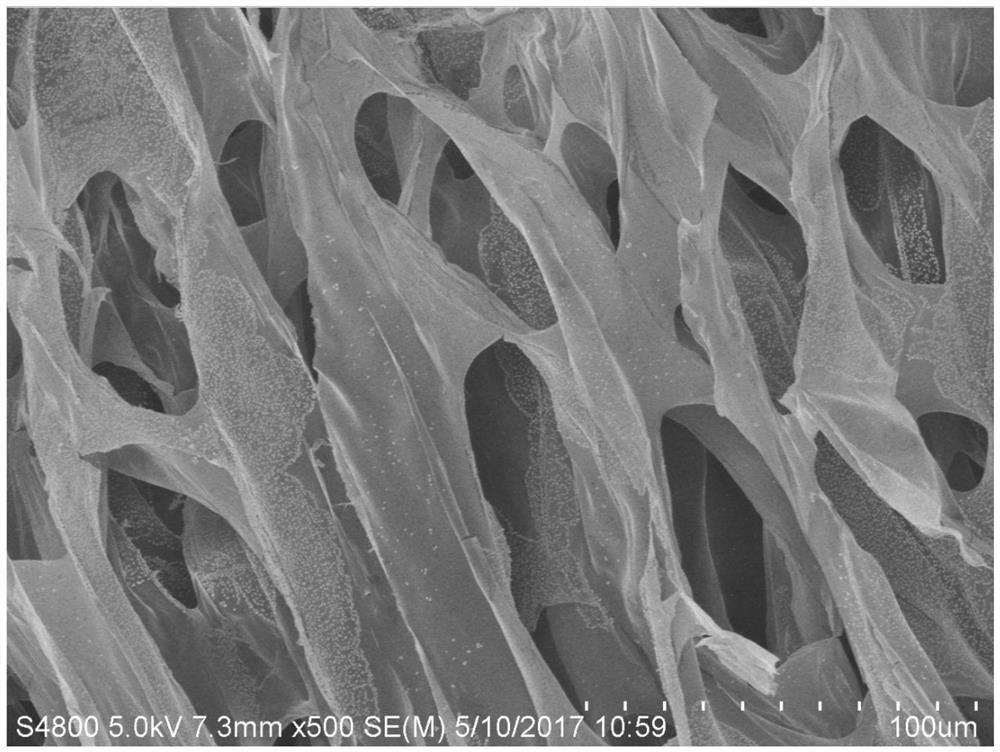

[0033] A functionalized nanocellulose hydrogel for 3D bioprinting, the preparation method is as follows:

[0034] 1) Add 0.01g TEMPO and 0.1g NaBr into 100mL deionized water, stir magnetically at 10°C and 300r / min for 10min to completely dissolve TEMPO and NaBr, then add 1g of cotton linters (length 2-3mm ) and 1gNaClO, adjust the pH of the system to 8 by adding 0.1mol / L NaOH solution dropwise, after reacting at 10°C for 3h, continue to add 1gNaClO 2 Stir and react at room temperature for 1 day, filter the oxidized cellulose pulp, wash with deionized water for more than 3 times, and dry to obtain TEMPO oxidized cellulose (TOC). 2 Perform acidification to oxidize incompletely oxidized aldehyde groups into carboxylate groups, which is conducive to better dispersion of nanofibers;

[0035] 2) Prepare TOCN dispersion: add 0.1g TOC to 99.9g distilled water and mechanically stir at 1600r / min for 10min to obtain 0.1wt% TOCN dispersion;

[0036]3) Preparation of nanocellulose gel: T...

Embodiment 2

[0039] A functionalized nanocellulose hydrogel for 3D bioprinting, the preparation method is as follows:

[0040] 1) Add 0.1g TEMPO and 0.1g NaBr to 100mL deionized water, stir magnetically at 10°C and 300r / min for 10min to completely dissolve TEMPO and NaBr, then add 1g cotton linters (length 2-3mm) to the above system and 1gNaClO, by dropping 0.1mol / L NaOH solution to adjust the pH value of the system to 8, after reacting at 10°C for 4h, continue to add 1gNaClO 2 Stir and react at room temperature for 1 day, filter the oxidized cellulose pulp, wash with deionized water for more than 3 times, and dry to obtain TEMPO oxidized cellulose (TOC);

[0041] 2) Prepare TOCN dispersion: add 0.1g TOC to 99.9g distilled water and mechanically stir at 1600r / min for 10min to obtain 0.1wt% TOCN dispersion;

[0042] 3) Preparation of nanocellulose gel: Concentrate the above TOCN dispersion to a concentration of 0.2%, heat it in a sterilized pot at 121°C for 30 minutes, and then mix the 0.2...

Embodiment 3

[0045] A 3D bioprinted nanocellulose gel can be prepared by the following method:

[0046] 1) Add 0.01g TEMPO and 0.1g NaBr to 100mL deionized water, stir magnetically at 10°C and 300r / min for 10min to completely dissolve TEMPO and NaBr, then add 1g cotton linters (length 2-3mm) to the above system and 0.5gNaClO, adjust the pH value of the system to 8 by adding 0.1mol / L NaOH solution dropwise, after reacting at 10°C for 3h, continue to add 0.5gNaClO 2 Stir and react at room temperature for 1 day, filter the oxidized cellulose pulp, wash with deionized water for more than 3 times, and dry to obtain TEMPO oxidized cellulose (TOC);

[0047] 2) Prepare TOCN dispersion: add 0.1g TOC to 99.9g distilled water and mechanically stir at 1600r / min for 10min to obtain 0.1wt% TOCN dispersion;

[0048] 3) Preparation of nanocellulose gel: Concentrate the above TOCN dispersion to 0.5%, heat it in a sterilized pot at 121°C for 30 minutes, and then mix the nanocellulose solution with a concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com