A kind of preparation method of aqueous polyacrylate emulsion

A technology of polyacrylate emulsion and acrylic acid monomer, which is applied in the direction of coating, etc., can solve the problems of affecting the shelf life, poor interface bonding performance, and the stability of the composite emulsion cannot be effectively guaranteed, so as to improve the shelf life and impact resistance. and anti-stone impact performance, improve the effect of interface bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

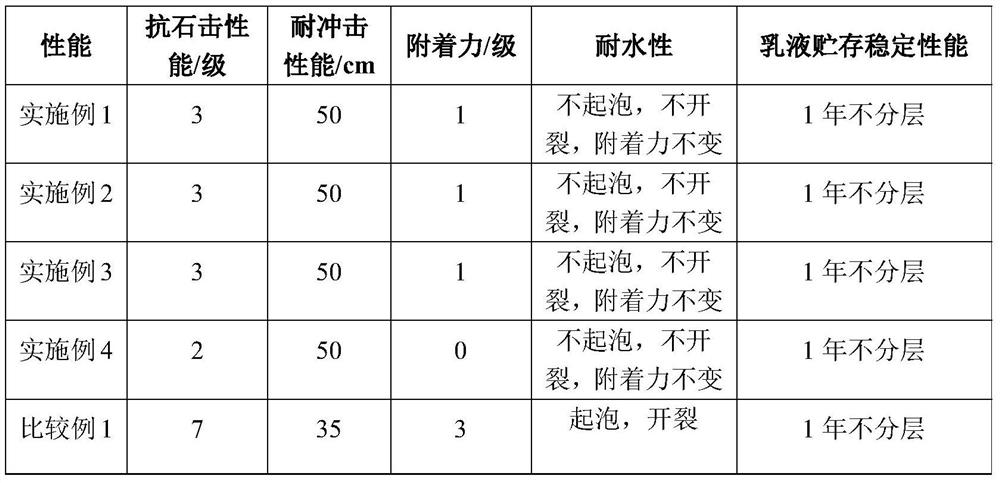

Examples

Embodiment 1

[0015] (1) Add 1.0 kg of acrylic acid monomer and 8.05 kg of glycolide monomer into the reactor, raise the temperature to 135 ° C, while stirring, add 0.009 kg of catalyst tin oxide to the reaction system, and stir for 2 hours to prepare Obtain a polyglycolide grafted acrylate oligomer;

[0016] (2) Add 30.17 kilograms of deionized water and 0.045 kilograms of octylphenol polyoxyethylene ether respectively to the oligomer obtained in step (1), raise the temperature to 65° C., and add 10 ml / min to the reaction system while stirring Speed dripping 1.81 kilograms of mass percent concentration is that 5% ammonium persulfate solution initiates polymerization reaction, after dropwise addition, insulation reaction is 90 minutes, is 7.5 with the sodium carbonate solution regulation system pH value of 20% with mass percent concentration, Cool to room temperature and discharge to obtain a polyglycolide-modified polyacrylate emulsion.

Embodiment 2

[0018] (1) 1.0 kg of acrylic acid monomer and 32.21 kg of glycolide monomer were added to the reactor, the temperature was raised to 160° C., while stirring, 0.166 kg of catalyst tin dichloride was added to the reaction system, and the reaction was stirred for 0.5 hours, That is, a polyglycolide grafted acrylate oligomer is obtained;

[0019] (2) Add 55.35 kilograms of deionized water and 0.332 kilograms of octylphenyl polyoxyethylene ether respectively to the oligomer obtained in step (1), raise the temperature to 85° C., while stirring, add 20 ml / Add 4.98 kilograms of azobisisobutylamidine hydrochloride solution dropwise at a rate of 20% by mass at a speed of 1 minute to initiate the polymerization reaction. The pH value of the system was adjusted to 8.0 by disodium hydrogen solution, cooled to room temperature and discharged to obtain a polyglycolide-modified polyacrylate emulsion.

Embodiment 3

[0021] (1) 1.0 kg of acrylic acid monomer and 16.11 kg of glycolide monomer are added to the reactor, the temperature is raised to 147 ° C, while stirring, 0.051 kg of catalyst stannous octoate is added to the reaction system, and the reaction is stirred for 1.5 hours, namely A polyglycolide grafted acrylate oligomer is obtained;

[0022] (2) Add 38.02 kg of deionized water and 0.128 kg of nonylphenol polyoxyethylene ether to the oligomer obtained in step (1) respectively, raise the temperature to 75°C, and pour the mixture into the reaction system at 15 ml / min while stirring. Add 2.28 kilograms of azobisisobutylamidine hydrochloride solution dropwise at a speed of 15% by mass to initiate the polymerization reaction. The pH value of the solution was adjusted to 8.5, and the solution was cooled to room temperature and discharged to obtain a polyglycolide-modified polyacrylate emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com