Vacuum brazing method for patch repairing of stator blade of aero-engine turbine

A technology for aero-engines and turbine stators, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of failure repair that cannot be ablated, ablation, scrapped blades, etc., and achieve small solder, good repair effect, and energy saving cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

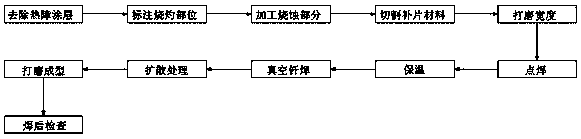

Image

Examples

Embodiment 1

[0030] A vacuum brazing method for repairing an aero-engine turbine stator blade patch, comprising the following steps;

[0031] S1. Removing the thermal barrier coating: remove the thermal barrier coating according to the thermal barrier coating mode of the turbine stator blade, and the removal method of the thermal barrier coating is chemical method, sand blowing or high-pressure water jet;

[0032] S2. Mark the ablation site;

[0033] S3. Process the ablation area: remove the ablation area at the marked position, and ensure that the removal area is a regular-shaped processing groove. The treatment method for removing the ablation area is CNC milling or EDM;

[0034] S4. Cutting the patch material: according to the size of the processing groove, cut the patch material of the corresponding size from the metal injection molded sheet;

[0035] S5. Grinding width: use a pneumatic grinding pen and a hard rotary file to grind the notch of the processing groove and the patch mater...

Embodiment 2

[0044] A vacuum brazing method for repairing an aero-engine turbine stator blade patch, comprising the following steps;

[0045] S1. Removing the thermal barrier coating: remove the thermal barrier coating according to the thermal barrier coating mode of the turbine stator blade, and the removal method of the thermal barrier coating is chemical method, sand blowing or high-pressure water jet;

[0046] S2. Mark the ablation site;

[0047] S3. Process the ablation area: remove the ablation area at the marked position, and ensure that the removal area is a regular-shaped processing groove. The treatment method for removing the ablation area is CNC milling or EDM;

[0048] S4. Cutting the patch material: according to the size of the processing groove, cut the patch material of the corresponding size from the metal injection molded sheet;

[0049] S5. Grinding width: use a pneumatic grinding pen and a hard rotary file to grind the notch of the processing groove and the patch mater...

Embodiment 3

[0058] A vacuum brazing method for repairing an aero-engine turbine stator blade patch, comprising the following steps;

[0059] S1. Removing the thermal barrier coating: remove the thermal barrier coating according to the thermal barrier coating mode of the turbine stator blade, and the removal method of the thermal barrier coating is chemical method, sand blowing or high-pressure water jet;

[0060] S2. Mark the ablation site;

[0061] S3. Process the ablation area: remove the ablation area at the marked position, and ensure that the removal area is a regular-shaped processing groove. The treatment method for removing the ablation area is CNC milling or EDM;

[0062] S4. Cutting the patch material: according to the size of the processing groove, cut the patch material of the corresponding size from the metal injection molded sheet;

[0063] S5. Grinding width: Use a pneumatic grinding pen and a hard rotary file to grind the notch of the processing groove and the patch mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com