Quick coating removing method of coating thermal forming steel

A technology for thermoforming steel and coating, which is applied in the directions of cleaning methods, cleaning methods and utensils using liquids, chemical instruments and methods, etc., which can solve the problems of insufficient processing stability, high laser cost, low production efficiency, etc. The effect of low input cost, low process cost and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

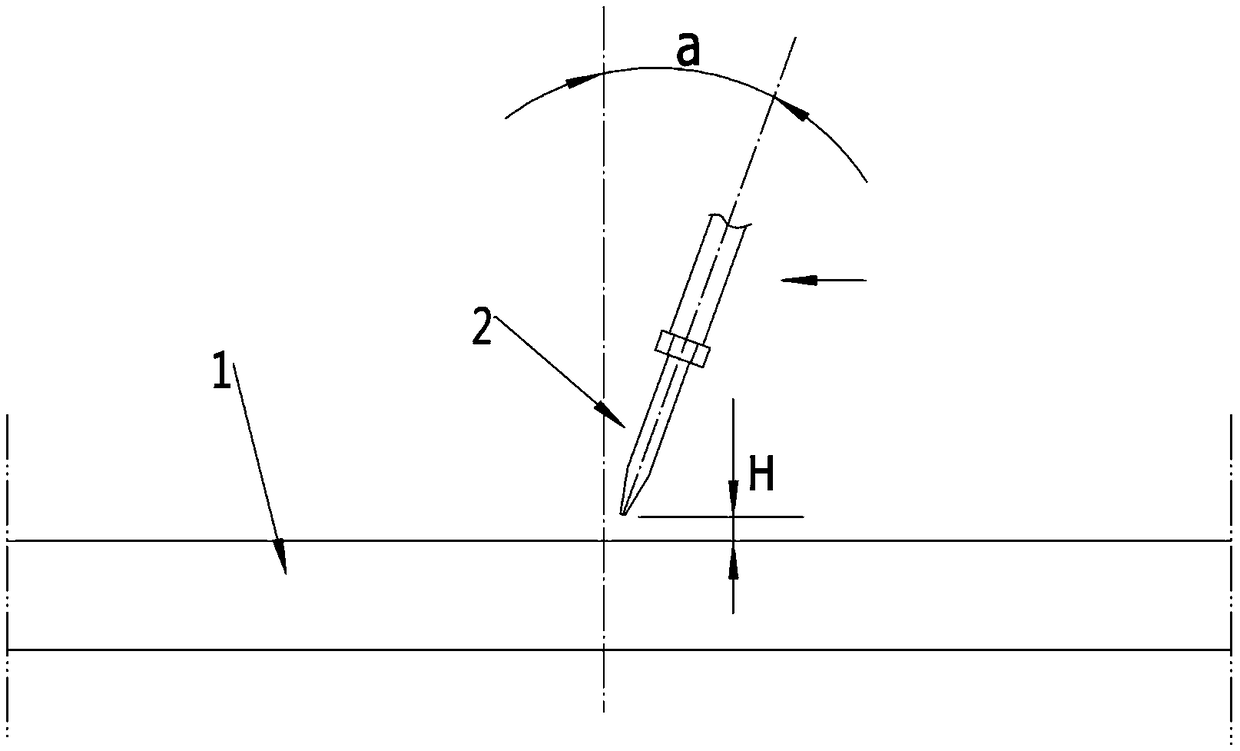

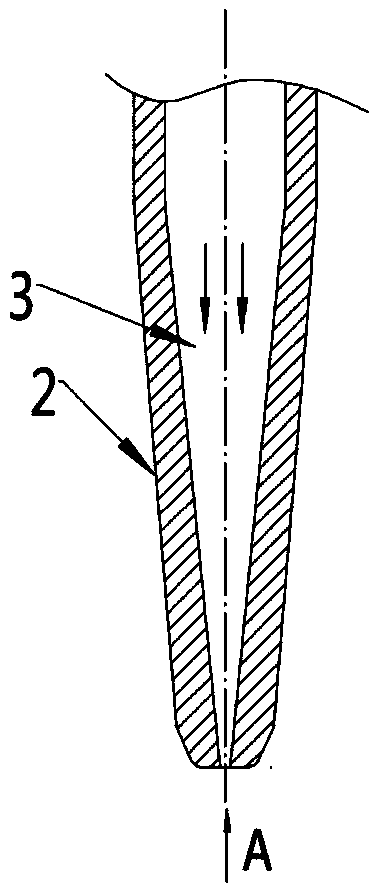

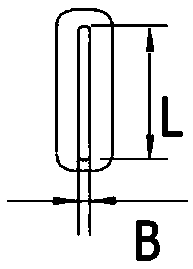

[0031] Example 1: For the alloy layer of 22MnB5 coated hot-formed steel, the removal depth is 28 μm. Select the water flow pressure of 380Mpa, the travel speed of 8m / min, the tip of the gun is 5mm away from the workpiece, and the tip of the gun is inclined at 15°. The metallographic photo after removal is shown in Figure 5 , the removal effect is good.

Embodiment 2

[0032] Example 2: The alloy layer and transition layer of the coating are removed for 22MnB5 coated hot-formed steel, and the removal depth is 42 μm. Select the water flow pressure of 420Mpa, the travel speed of 6m / min, the distance between the gun head and the workpiece is 4mm, and the gun head is inclined at 15°. The metallographic photo after removal is shown in Figure 6 , the removal effect is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com