Three-dimensional graphene macroscopic body loaded nanoscale zero-valent iron composite material and preparation method thereof

A graphene macro-body, nano-zero valent iron technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc. The effect of enriching organic pollutants and excellent adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A method for preparing a three-dimensional graphene macroscopic body loaded nano-zero-valent iron composite material, characterized in that it comprises the following steps:

[0037] Step 1, the preparation of three-dimensional graphene macroscopic body;

[0038] 1.1 Prepare 20-100 mL of graphene oxide solution with a mass concentration of 2-8 mg / mL, and obtain a colloidal dispersion after ultrasonication for 1-3 hours;

[0039] 1.2 Add hydrazine hydrate (concentration: 55%) with a volume percentage of 2vol% to 5vol% to the obtained colloidal dispersion, and mix ultrasonically for 10 to 30 minutes to obtain a reaction solution;

[0040] 1.3 Transfer the reaction solution obtained in the previous step to a reaction kettle lined with polytetrafluoroethylene, and conduct a hydrothermal reaction at 100-180°C for 3-6 hours;

[0041] 1.4 After the reaction is completed, naturally cool to room temperature, and the obtained product is washed with deionized water to obtain a re...

Embodiment 1

[0051] A method for preparing a three-dimensional graphene macroscopic body loaded nano-zero-valent iron composite material, characterized in that it comprises the following steps:

[0052] Step 1, the preparation of three-dimensional graphene macroscopic body;

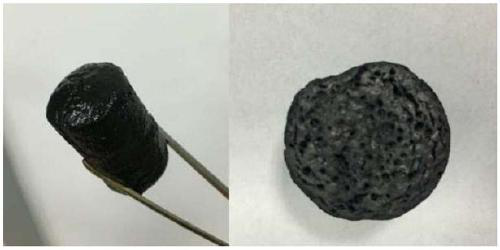

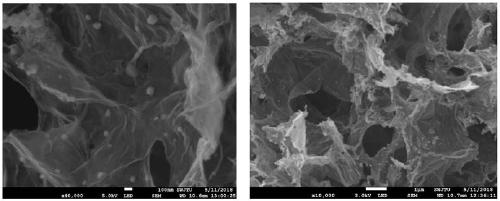

[0053] Prepare 20mL of graphene oxide solution with a mass concentration of 2mg / mL, obtain a colloidal dispersion after ultrasonication for 1h; add 1mL of hydrazine hydrate (concentration 55%) to the obtained colloidal dispersion and mix ultrasonically for 10min to obtain a reaction solution; The reaction solution obtained in the previous step was transferred to a reaction kettle lined with polytetrafluoroethylene, and hydrothermally reacted at 100°C for 3 hours; 2h, the reduced graphene oxide hydrogel was obtained, and then freeze-dried in a freeze dryer for 24h to obtain a fluffy and porous three-dimensional graphene macrobody;

[0054] Step 2, the loading of nanometer zero valent iron:

[0055] 2.1 Add 100mL, 0.1...

Embodiment 2

[0061] A method for preparing a three-dimensional graphene macroscopic body loaded nano-zero-valent iron composite material, characterized in that it comprises the following steps:

[0062] Step 1, the preparation of three-dimensional graphene macroscopic body;

[0063] Prepare 40 mL of graphene oxide solution with a mass concentration of 3 mg / mL, and obtain a colloidal dispersion after ultrasonication for 2 hours; add 1.5 mL of hydrazine hydrate (concentration 55%) to the obtained colloidal dispersion and ultrasonically mix for 20 minutes to obtain a reaction solution; Transfer the reaction solution obtained in the previous step to a reaction kettle with a polytetrafluoroethylene liner, and conduct a hydrothermal reaction at 120°C for 4 hours; After 2 hours, the reduced graphene oxide hydrogel was obtained, and then freeze-dried for 24 hours in a freeze dryer to obtain a fluffy and porous three-dimensional graphene macrobody;

[0064] Step 2, the loading of nanometer zero va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com