A high-performance micro-mixer used in ultra-high performance liquid chromatography analyzer

A chromatographic analyzer and ultra-high-efficiency liquid phase technology, applied in the field of micro-mixers, can solve the problems of high cost and unstable mixing performance of micro-mixers, and achieve the effects of prolonging the working life, prolonging the molecular diffusion time, and enhancing the convection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

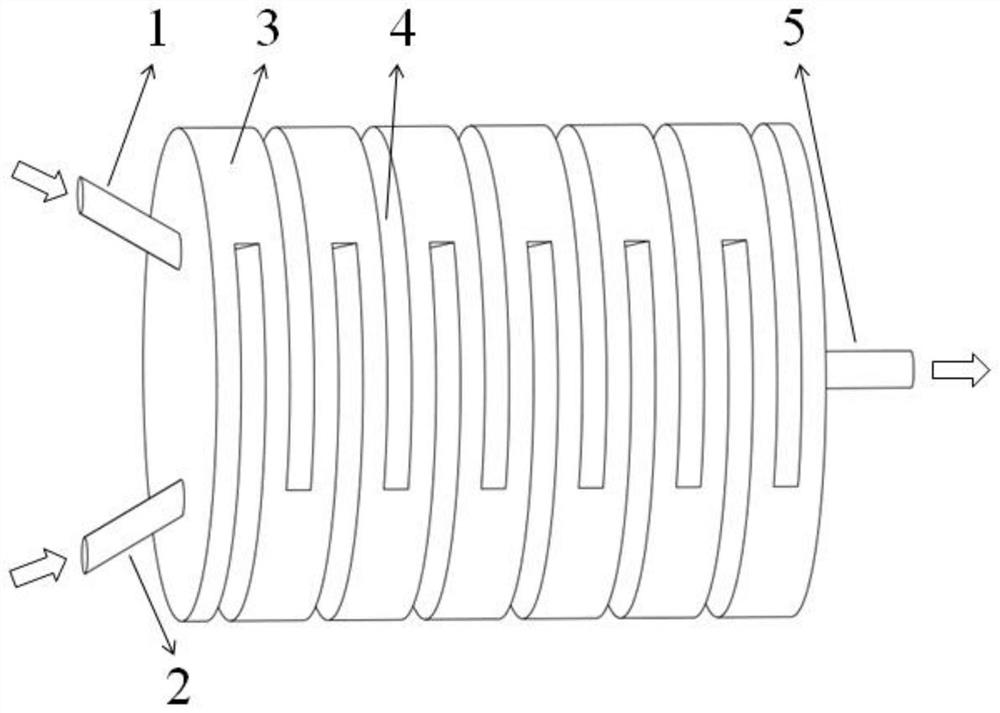

[0026] Since the present invention is based on a micro-scale mixer, the requirements for processing methods are relatively high, and the present invention needs to work in a high-pressure environment, and the traditional micro-mixer manufacturing process cannot meet the requirements of the present invention. Based on the above considerations, A high-performance micro-mixer used in ultra-high performance liquid chromatography analyzers of the present invention is processed and manufactured using the additive manufacturing technology of laser metal powder sintering and 3D printing.

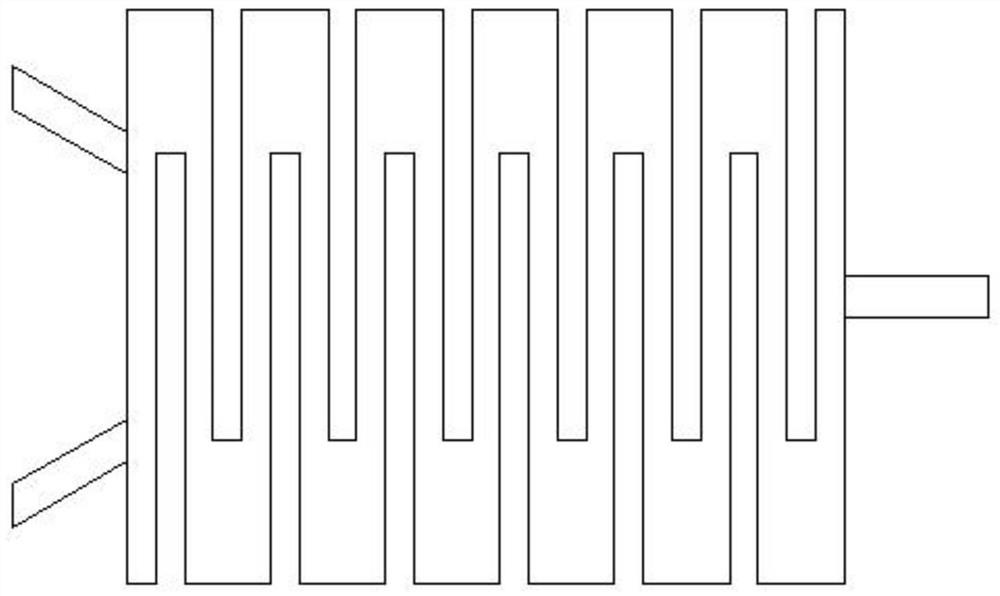

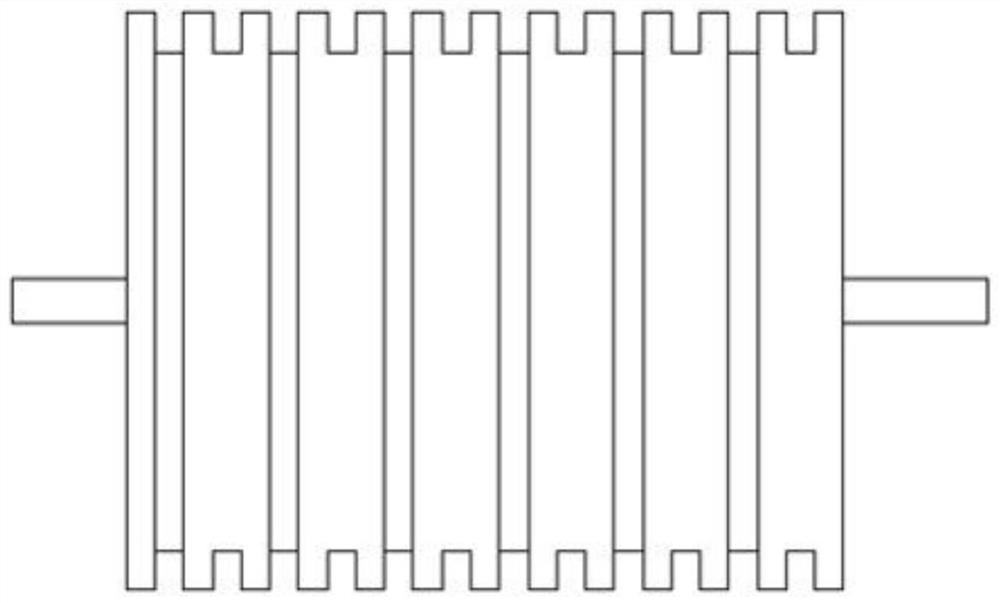

[0027] Two different solvents flow into the mixing chamber at equal speed from the two inlet channels respectively, and complete the mixing while flowing in a square wave path in the mixing chamber, and finally the mixed solvent flows out from the outlet channel on the right to complete the mixing.

[0028] The two solvents are fully mixed in the mixing chamber by means of molecular diffusion and con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com