High Frequency Laser Pulse Method Applied to Dissimilar Metal Composite Heat Source Welding

A dissimilar metal, laser pulse technology, applied in welding equipment, metal processing equipment, laser welding equipment and other directions, can solve the problems of poor mechanical properties, low flatness, poor symmetry, etc., to prevent stress concentration, enhance convection effect, compensate for The effect of deformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

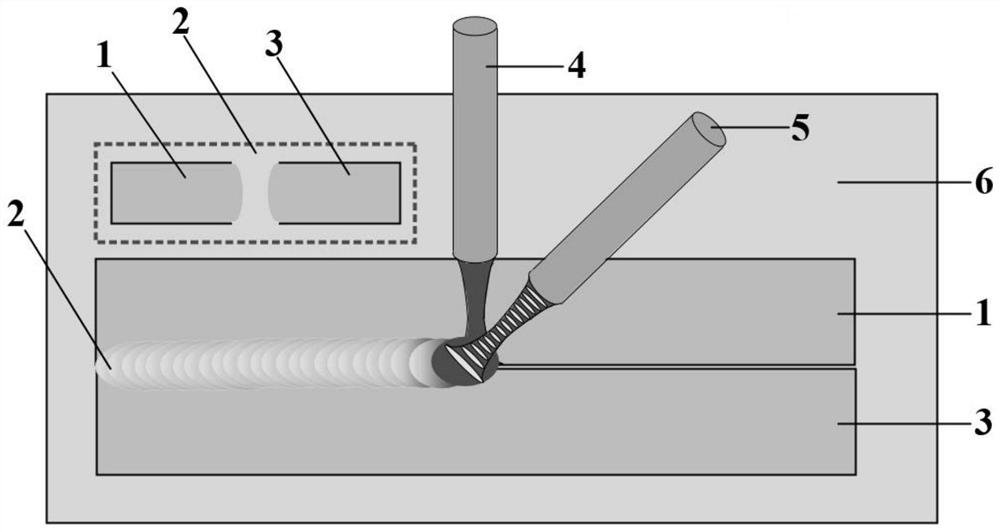

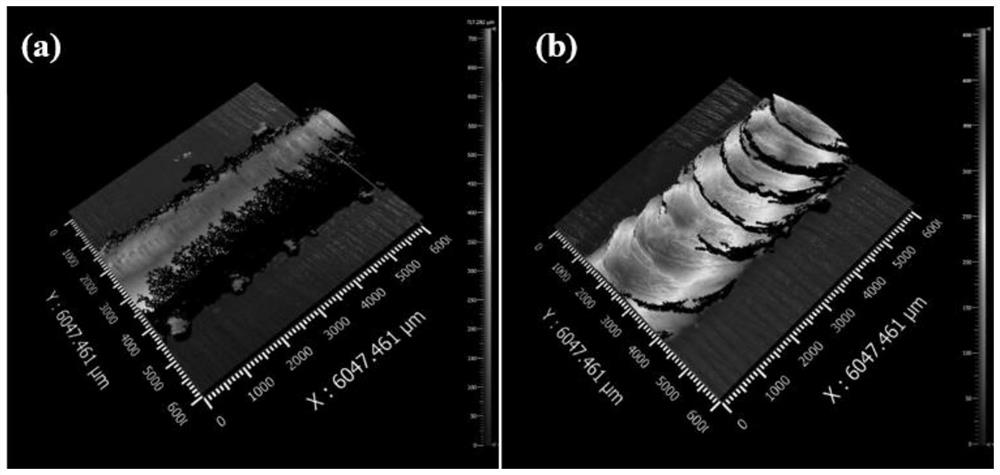

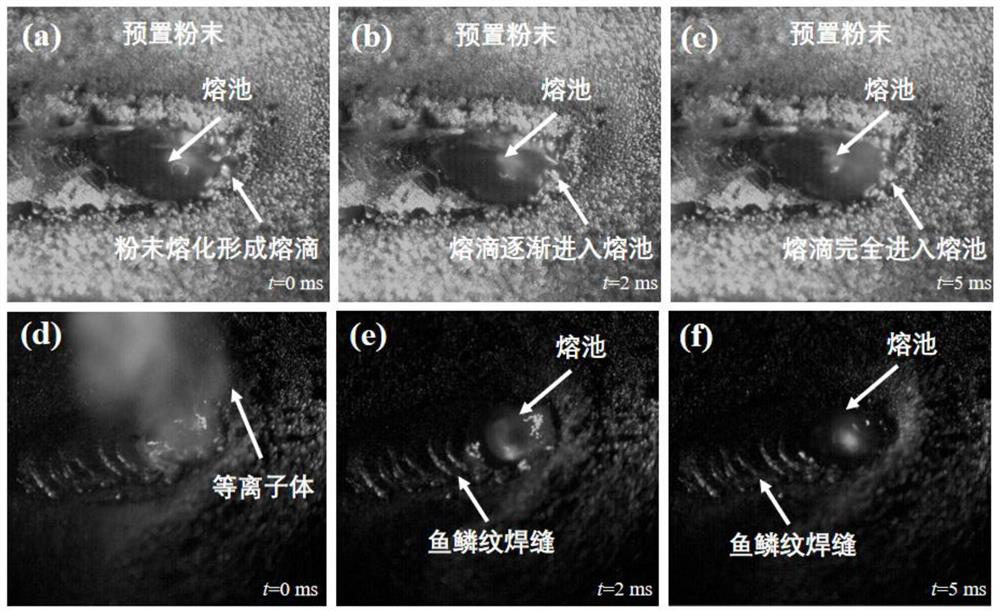

[0039] The Nd: YAG solid continuous laser is used as a welding heat source, and the nanosecond pulse laser is used as a high-frequency pulse laser heat source. The continuous laser power is 1500W, the spot diameter is 3 mm, the travel speed is 4mm / s, the nanosecond pulse laser pulse energy is 2J, the pulse spot has a diameter of 1.3 mm, the pulse frequency is 5 Hz, and the pulsed laser spot is coincident with the central convergence laser spot. figure 2 A comparative diagram of the effects of the present invention. The three-dimensional shape of the weld joint when the white light interferometer is used: When the pulsed laser intervention is not used, the material is melted under the laser irradiation of high energy densities, and the melt is fluctuated inside the molten pool. With the movement of the laser heat source, the molten pool melt is condensed, a weld having a raised morphology is formed; under the action of the pulsed laser shock wave, the melt in the molten tank is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com