Method for adsorbing and removing chlorine from strong acidic solution

A strong acid, dechlorination technology, applied in the field of adsorption and dechlorination, to achieve good dechlorination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

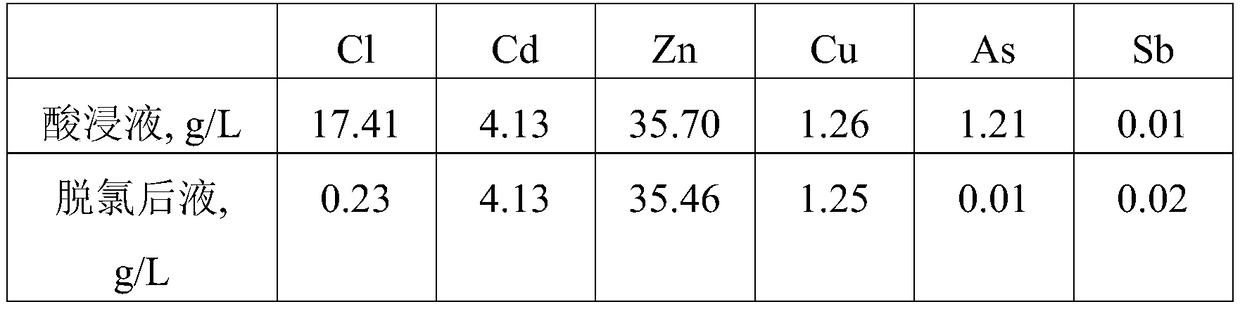

Embodiment 1

[0040] Take H + The sulfuric acid leaching solution of metallurgical materials with a concentration of 1.5mol / L is 1.5m 3 According to the 4.5 times of the theoretical amount of chlorine converted into antimony oxychloride, add the hydrated oxide of trivalent antimony, stir at room temperature for 2.5 hours to perform a dechlorination, and filter to obtain a dechlorination filter residue and a dechlorination liquid. Then add antimony pentoxide according to the conversion of the antimony in the liquid after the first dechlorination to 2.5 times the theoretical amount of tetravalent antimony, stir at 65°C for 3.5h to carry out the second dechlorination, and filter to obtain the second dechlorination filter residue and the second dechlorination after liquid. The resulting liquid after secondary dechlorination contains 0.23g / L Cl and 0.02g / L Sb. The acid in it is firstly separated and recovered by diffusion dialysis, and the recovered acid is returned to prepare the leaching solu...

Embodiment 2

[0043] Take 0.5m of smelting flue gas scrubbing acid 3 According to the 1.5 times of the theoretical amount of chlorine converted into antimony oxychloride, add the hydrated oxide of trivalent antimony, stir at room temperature for 1.5h to perform a dechlorination, and filter to obtain a dechlorination filter residue and a dechlorination liquid. Then add antimony acid according to the conversion of the antimony in the liquid after the primary dechlorination to twice the theoretical amount of tetravalent antimony, stir at 95°C for 1.5h for secondary dechlorination, and filter to obtain the secondary dechlorination filter residue and the secondary dechlorination liquid . The obtained solution after secondary dechlorination contains 0.19g / L Cl and 0.02g / L Sb, and dilute acid solution is obtained after defluorination. The resulting primary dechlorination filter residue is added to water at a solid-to-liquid ratio of 1:4g / mL, and sodium carbonate is added to adjust the pH of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com