A method for manufacture a wireless communication antenna

A wireless communication and manufacturing method technology, applied to antennas, loop antennas, antenna parts, etc., can solve the problem of thickening the overall thickness and achieve the effects of ensuring productivity, eliminating common processes, and efficient charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Referring to the accompanying drawings, the preferred embodiment of the method for manufacturing a wireless communication antenna of the present invention is described. There may be multiple embodiments. Through such an embodiment, the purpose, features and advantages of the present invention can be better understood.

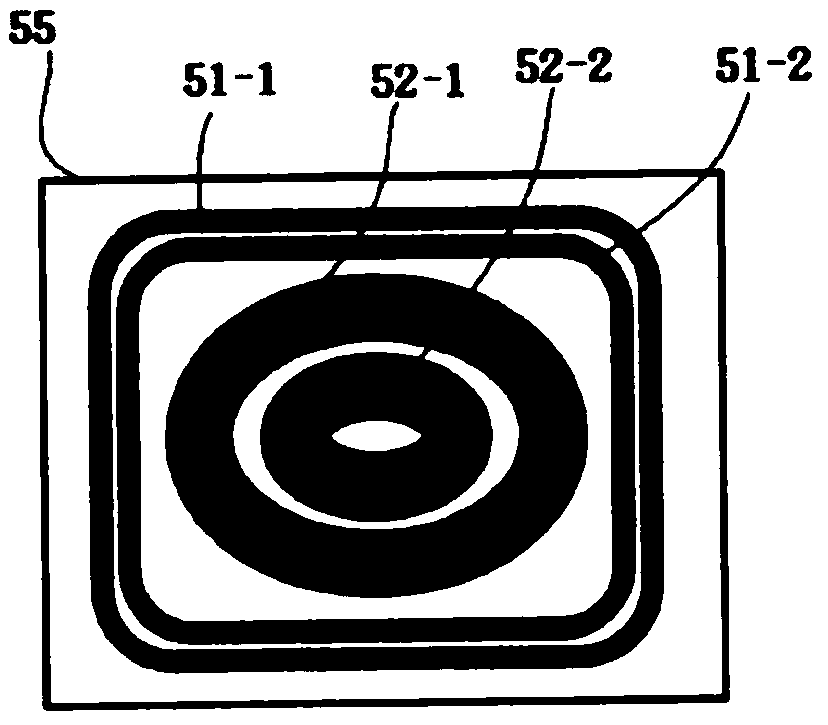

[0075] Figure 8 is a process diagram showing a method for manufacturing a wireless communication antenna of the present invention, Figure 9a is a cross-sectional view showing a metal thin film, Figure 9b is a cross-sectional view for explaining each step of the method for manufacturing the wireless communication antenna according to the first embodiment of the present invention, Figure 9c It is a sectional view for explaining each step of the method of manufacturing the wireless communication antenna according to the second embodiment of the present invention. In the following description, the surface and the inside are distinguished from each othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com