A kind of magnetic porous carbon material and preparation method thereof

A porous carbon material and magnetic technology, applied in the direction of magnetic materials, carbon preparation/purification, magnetic objects, etc., can solve the problems of low reutilization rate and easy phase separation of magnetic carbon adsorption materials, so as to improve the reutilization rate, Excellent adsorption performance and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

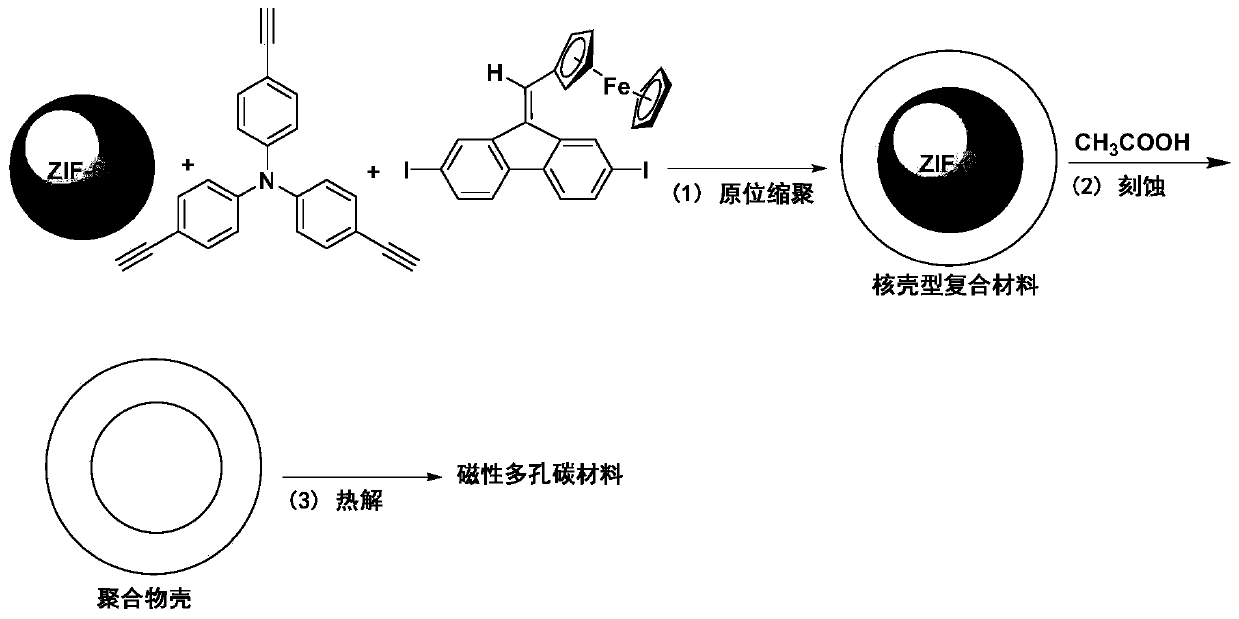

[0041] The preparation roadmap of the magnetic porous carbon material of the present embodiment is as follows figure 1 It should be noted that the shapes of the structure-oriented template ZIF-67, core-shell composites, and polymer shells in this roadmap do not represent their actual morphology, and the shapes in the figure are only used to more directly understand The preparation process of magnetic porous carbon materials is described.

[0042] (1) Add 1g ZIF-67, 40mg Pd(PPh 3 ) 2 Cl 2 And 10.6mg CuI, vacuumize, backfill with nitrogen, under nitrogen protection, add 50mL triethylamine and 20mL tetrahydrofuran, stir vigorously at room temperature for 1h; then add 2,7-diiodo-9-(ferrocenevinyl)-9H -Fluorene (3mmol) and tris(4-ethynylphenyl)amine (2mmol) were added to the reaction flask, stirred and dissolved, heated to 90°C and refluxed for 24h; The filter cake was washed with acetone, methanol, and 1,2-dichloroethane to obtain the core-shell composite material ZIF-67@polym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com