A measurement method based on nanometer metal hole array

A technology of nano metal and measurement method, applied in the direction of volume measurement instrument/method, measurement device, nanotechnology, etc., to achieve the effect of mass production cost, less equipment and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

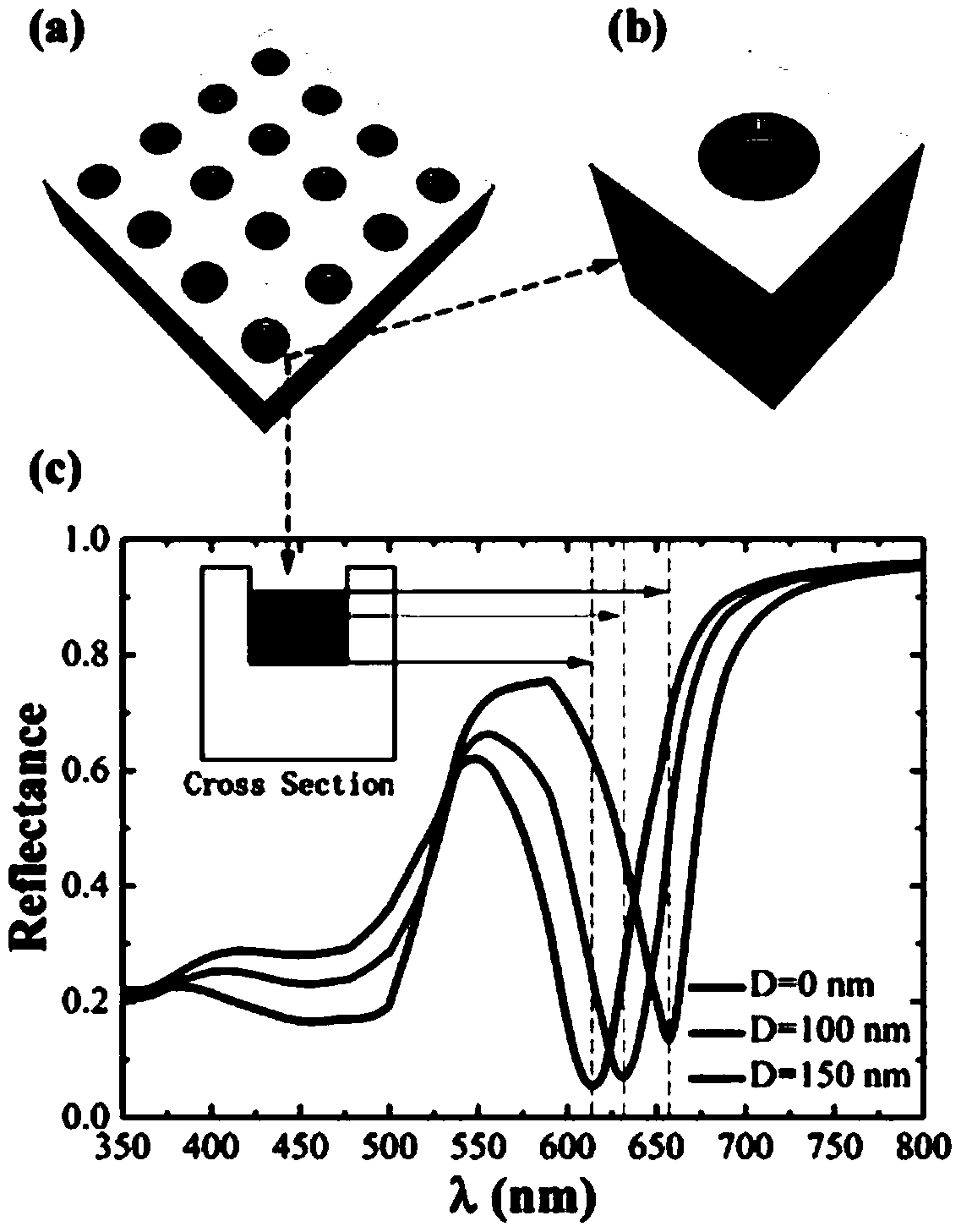

[0028] Embodiment 1: Select a silicon wafer polished on one side as the substrate, and obtain a nanometer metal hole array structure on the substrate by nanoimprinting, and deposit 500 nm of Au on the substrate by electron beam evaporation, so that on the substrate Au nanometer metal hole array structure is obtained on the surface.

[0029] First, the method of controlling variables is used to explore the effect of the depth of nano-metal pores on the reflectance spectrum. Here, the period of the nano-metal hole is selected as 500 nm, and the radius of the nano-metal hole is 125 nm. When simulating with COMSOL, the depth of the nano-metal hole is changed from 10nm to 496nm every 2nm and the parameters are scanned. After processing the obtained data results, it can be obtained: when the depth of the nano-metal hole is less than 50nm, the reflection spectrum has no Obvious resonance point. This is because the nano-metal pores are very shallow at this time, which is equivalent ...

Embodiment 2

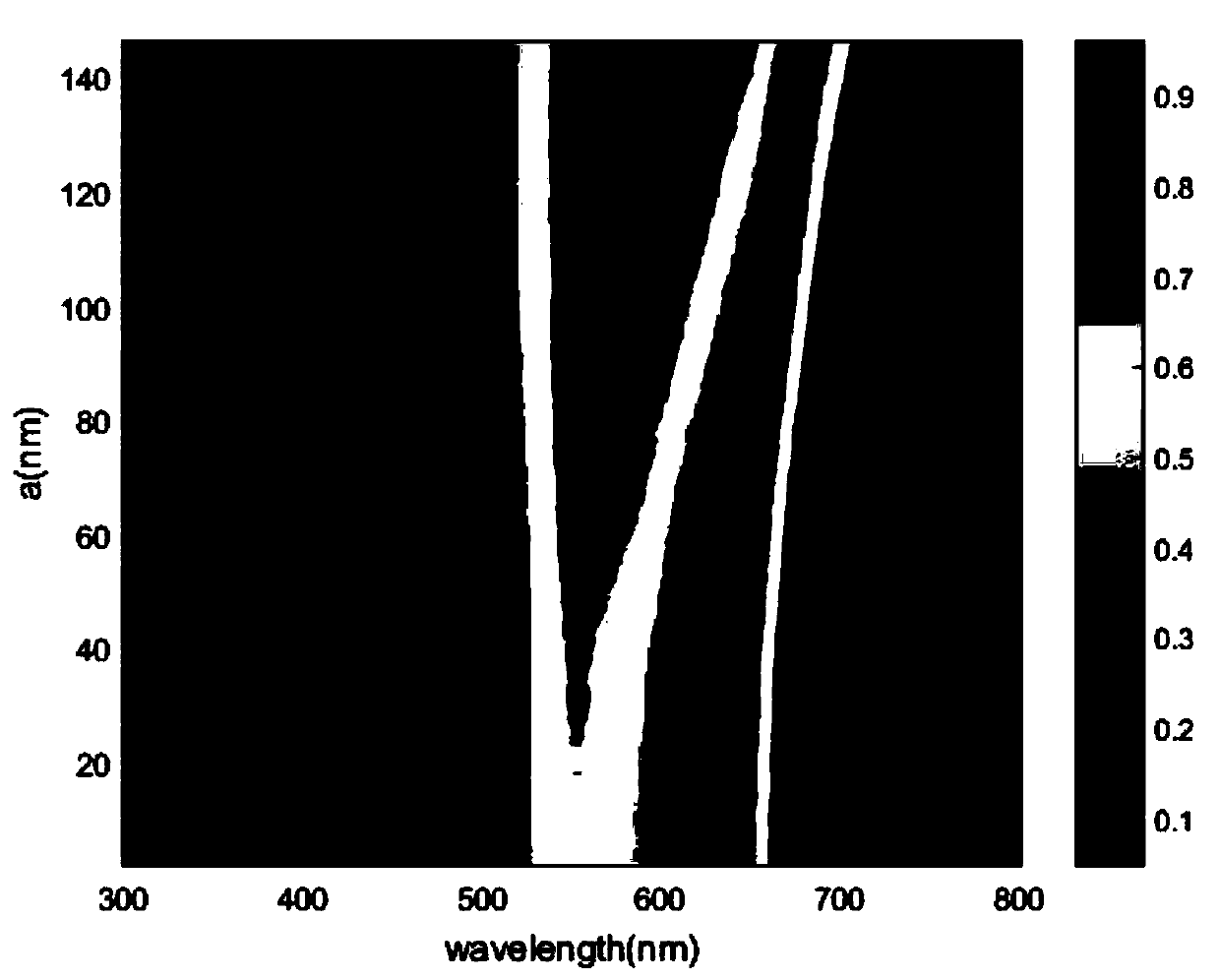

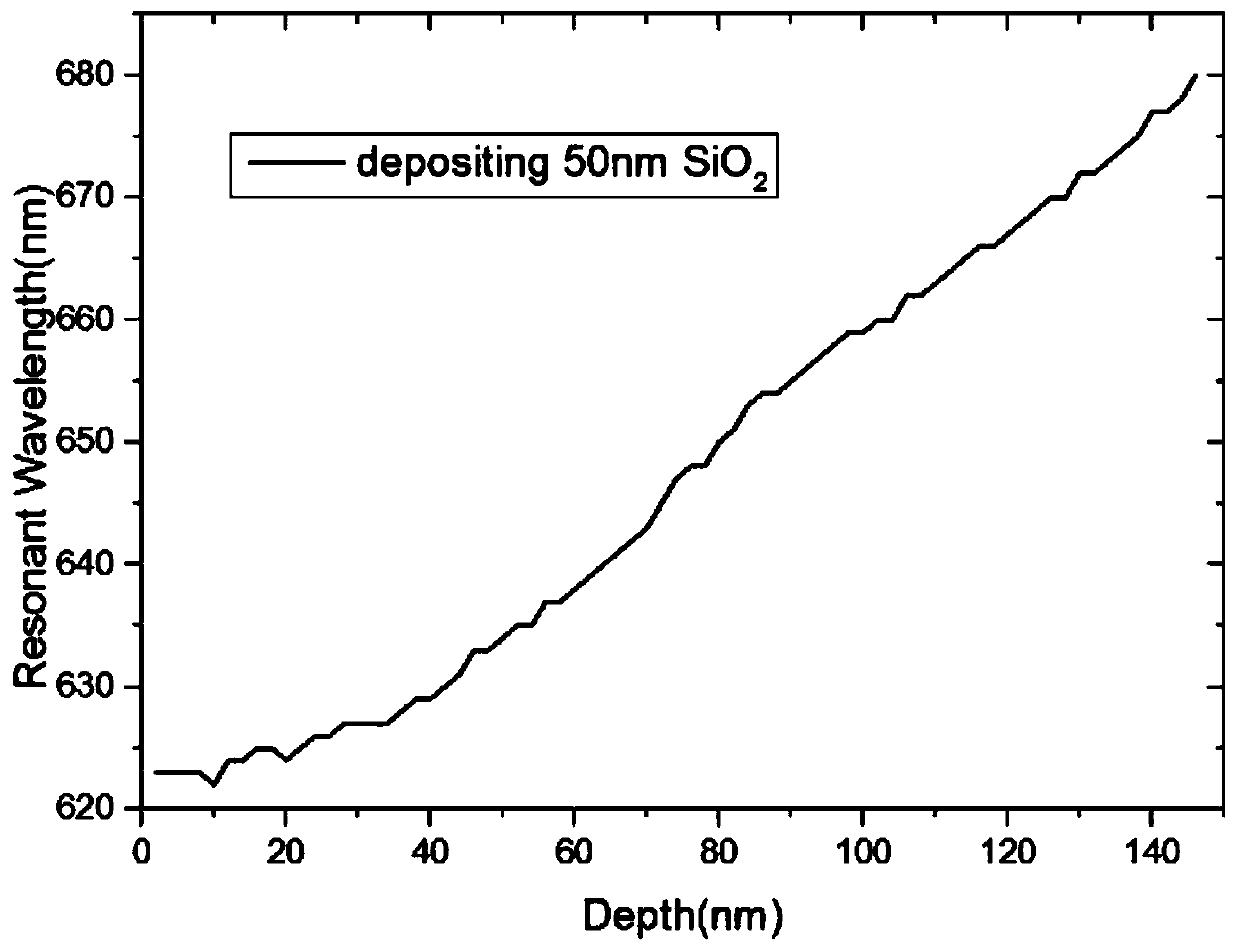

[0030]Embodiment 2: After investigating the effect of the period radius depth of the nano-metal hole when no liquid is contained in the nano-metal hole, the effects of different sizes of the nano-metal hole in measuring the liquid volume are discussed in detail next. Take the values of the radius r as 30nm, 90nm, 105nm, 120nm, 150nm, and 190nm. Here, the liquid in the nano-metal hole is selected as water, so that the water depth in the nano-metal hole changes from 2nm to 150nm, and one is taken every 2nm. value. After processing the reflection spectrum obtained by changing the water depth at different radii, it was found that the resonance point of the reflection spectrum basically does not change with the increase of the water depth, which indicates that the radius of the nano-metal hole is too small, and the nano-metal hole structure does not measure the liquid volume. Effect. Similarly, if the radius of the nano-metal hole is too large, there is also no measurement effec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com