Two-dimensional magnetically driven scanning micromirror based on mems technology and its preparation method

A technology of scanning micromirror and technology, which is applied to the technology for producing decorative surface effects, metal material coating technology, microstructure devices composed of deformable elements, etc., can solve the difficulty of integrating micro-actuating devices, sensors and There are huge differences in the working principle and structural scheme of the driver, and there is no process standard for MEMS devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

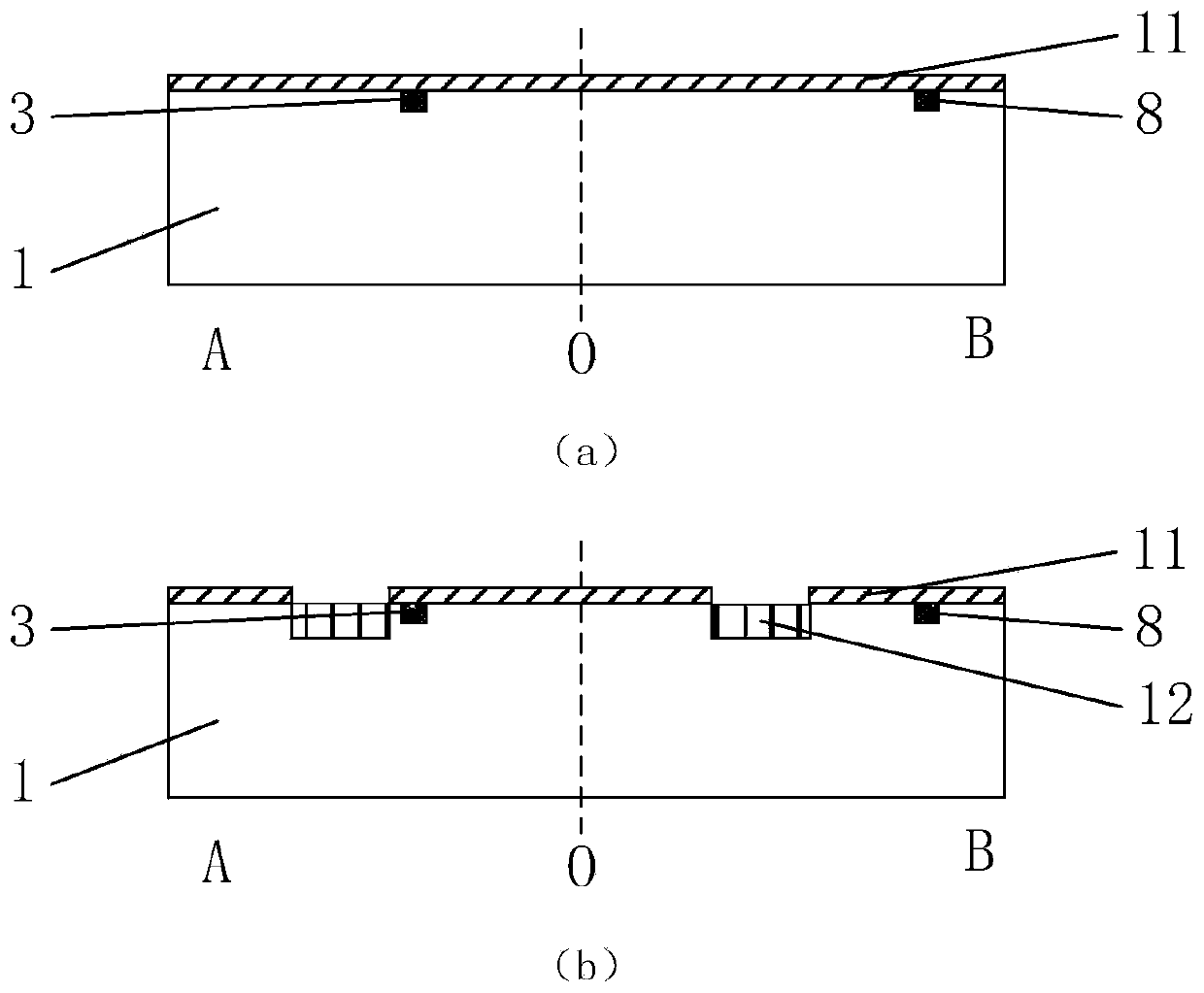

[0038] A kind of preparation method of the two-dimensional magnetic drive scanning micromirror based on MEMS technology of the present invention, comprises the following steps:

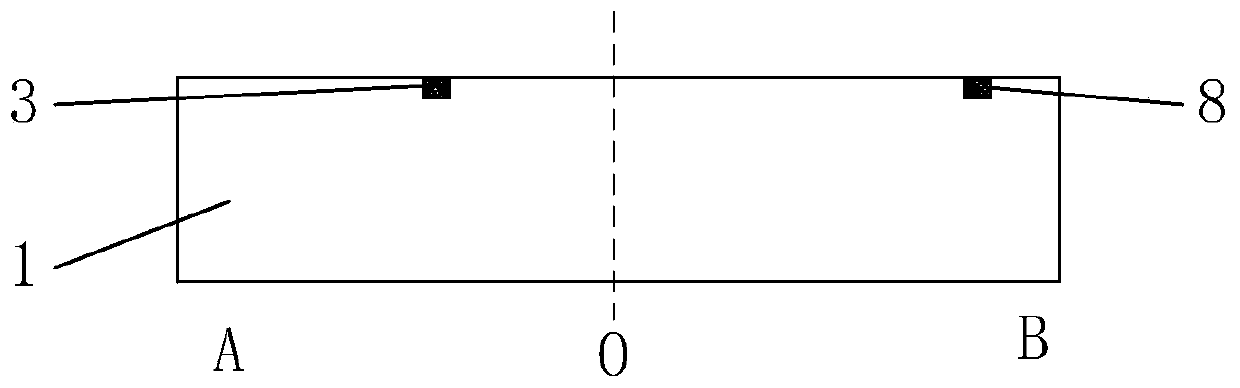

[0039] Step 1, preparing the first piezoresistive sensor 3 and the second piezoresistive sensor 8 on the silicon substrate 1;

[0040] 1.1. Photolithography forms the graphics of the first piezoresistive sensor 3 and the second piezoresistive sensor 8:

[0041] Coating positive photoresist on the silicon substrate 1, covering the mask plate provided with the patterns of the first piezoresistive sensor 3 and the second piezoresistive sensor 8, and performing exposure treatment to obtain the first piezoresistive sensor 3 and the second piezoresistive sensor The graph of resistance sensor 8.

[0042] 1.2. Perform reactive ion etching on the silicon substrate 1 to obtain the structures of the first piezoresistive sensor 3 and the second piezoresistive sensor 8, and obtain an alignment mark structure;

...

Embodiment

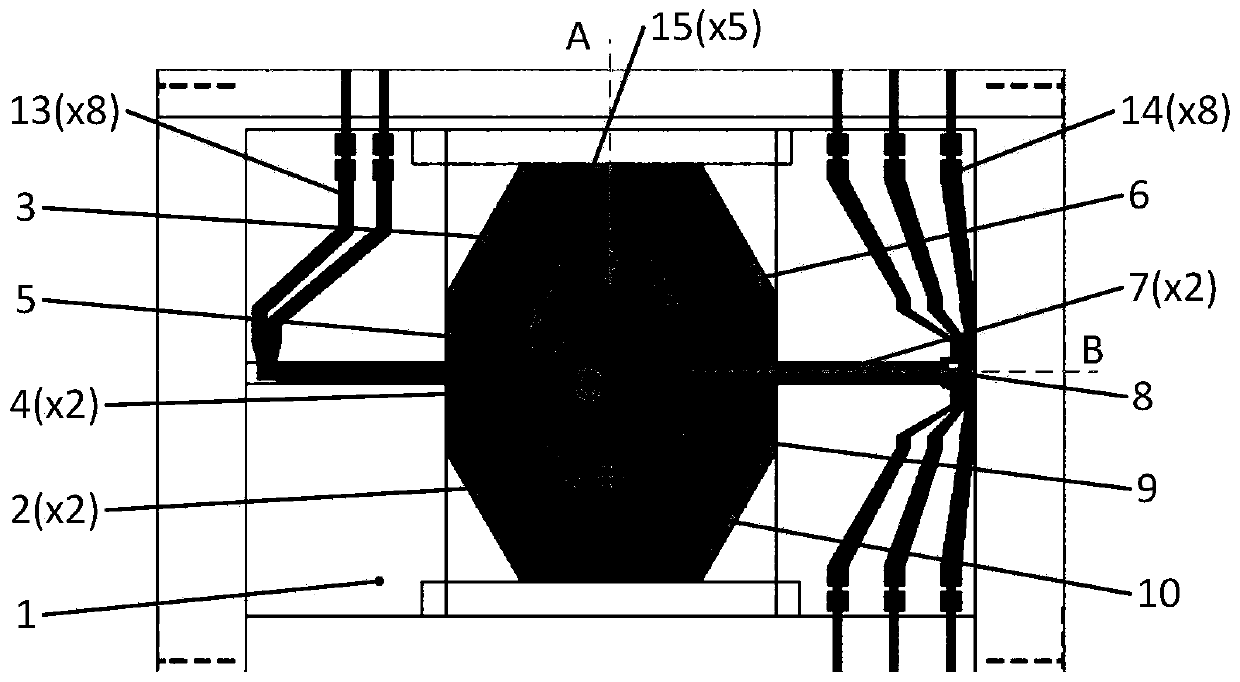

[0084] combine Figure 1 to Figure 7 , a two-dimensional magnetically driven scanning micromirror based on MEMS technology of the present invention, comprising a silicon substrate 1, a mirror substrate 6, a first piezoresistive sensor 3, a second piezoresistive sensor 8, a coil 9, a frame 10, an oxide insulating layer 4. Metal mirror layer 5, metal electrodes 14, coil leads 13, metal connecting wires, two first cantilever beams 2 and two second cantilever beams 7 arranged symmetrically to the center of the mirror base 6, and the two first cantilever beams 2 is perpendicular to the line connecting the two second cantilever beams 7;

[0085] The specific preparation process includes the following steps:

[0086] Step 1, preparing the first piezoresistive sensor 3 and the second piezoresistive sensor 8; as figure 2 shown;

[0087] 1.1. Photolithography forms the graphics of the first piezoresistive sensor 3 and the second piezoresistive sensor 8:

[0088] Coating AZ5214 posi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com