Angle Changing Device Based on Off-Axis Parabolic Mirror for Large Aperture Parallel Beam

An off-axis parabolic mirror and parallel beam technology, which is applied in the optical field, can solve the problems of increasing the measurement system and data processing difficulty and complexity, difficulty in changing the angle of large-diameter parallel beams, and difficulty in manufacturing and installing mirrors. Good parallel quality, large diameter, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

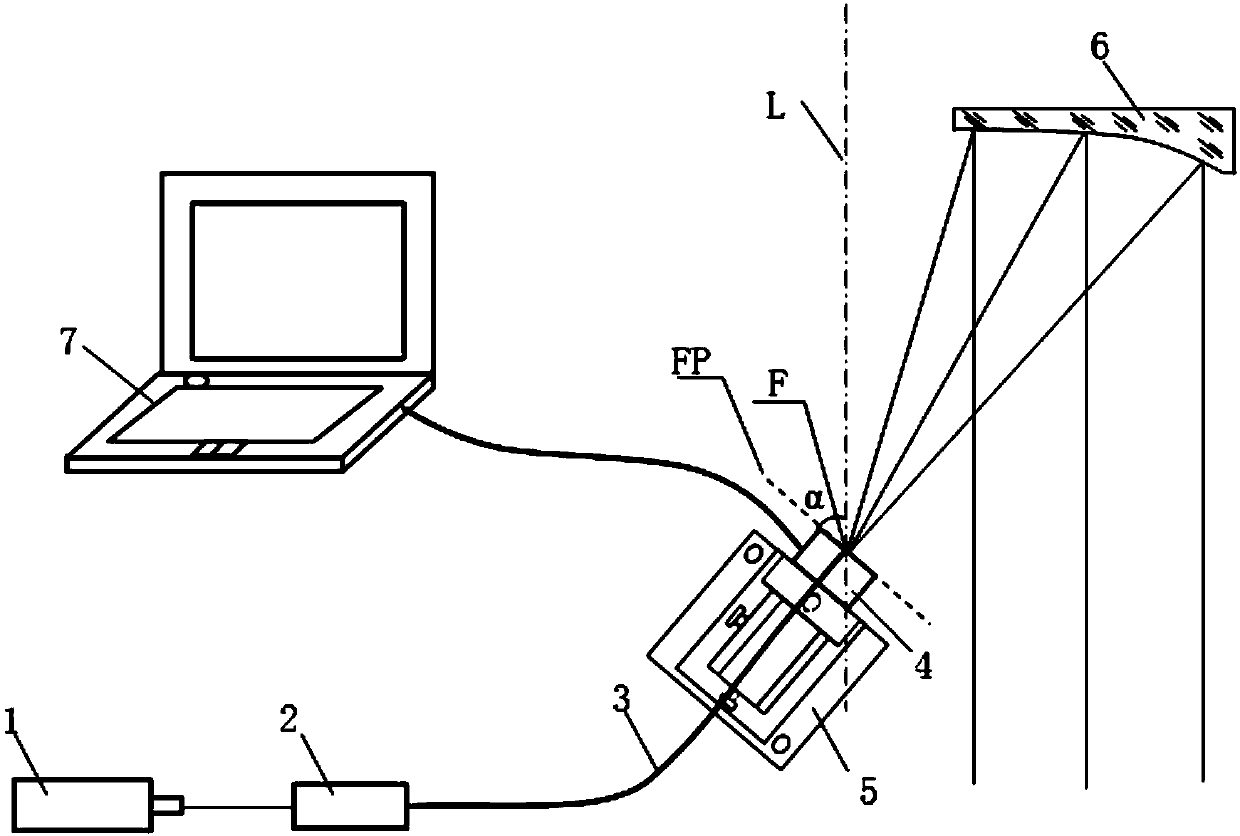

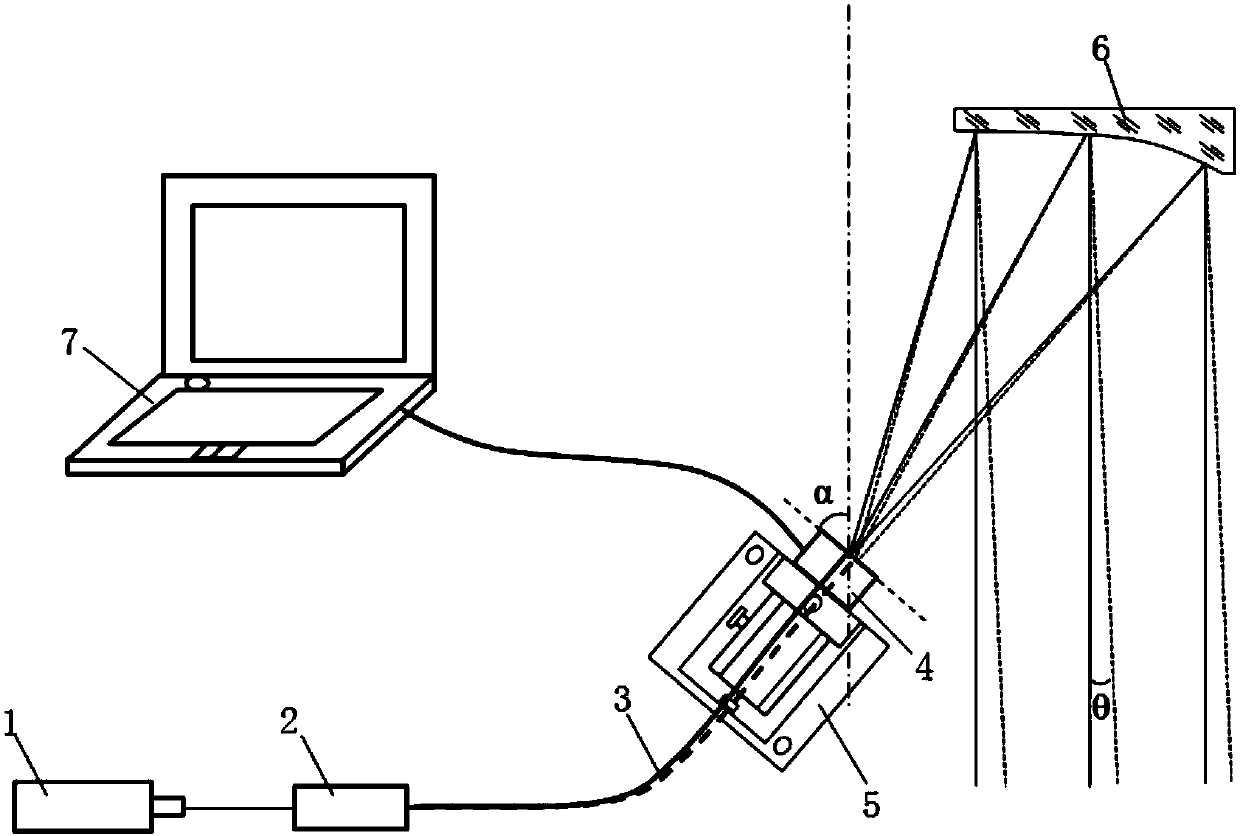

[0018] see figure 1 , the angle changing device based on off-axis parabolic mirror large-diameter parallel beams disclosed in the present invention, including laser 1, fiber coupler 2, single-mode optical fiber 3, precision linear displacement driver 4, five-dimensional adjustment frame 5, off-axis parabolic mirror 6 And control terminal 7 (can be terminals such as computer, panel computer, mobile communication equipment). The fiber coupler 2 has the ability to couple the laser beam of the laser 1 into a single-mode fiber 3 . The input end of the single-mode optical fiber 3 is fixed on the fiber coupler 2, the output end is fixed on the precision linear displacement driver 4 and is flush with the end face of the precision linear displacement driver 4; the precision linear displacement driver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com