a transmission diaphragm

A membrane disk and disk surface technology, which is applied to elastic couplings, mechanical equipment, couplings, etc., can solve the problems of difficult processing and expensive imported transmission membrane disks, and achieve the advantages of convenient processing and production and high dynamic balance performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

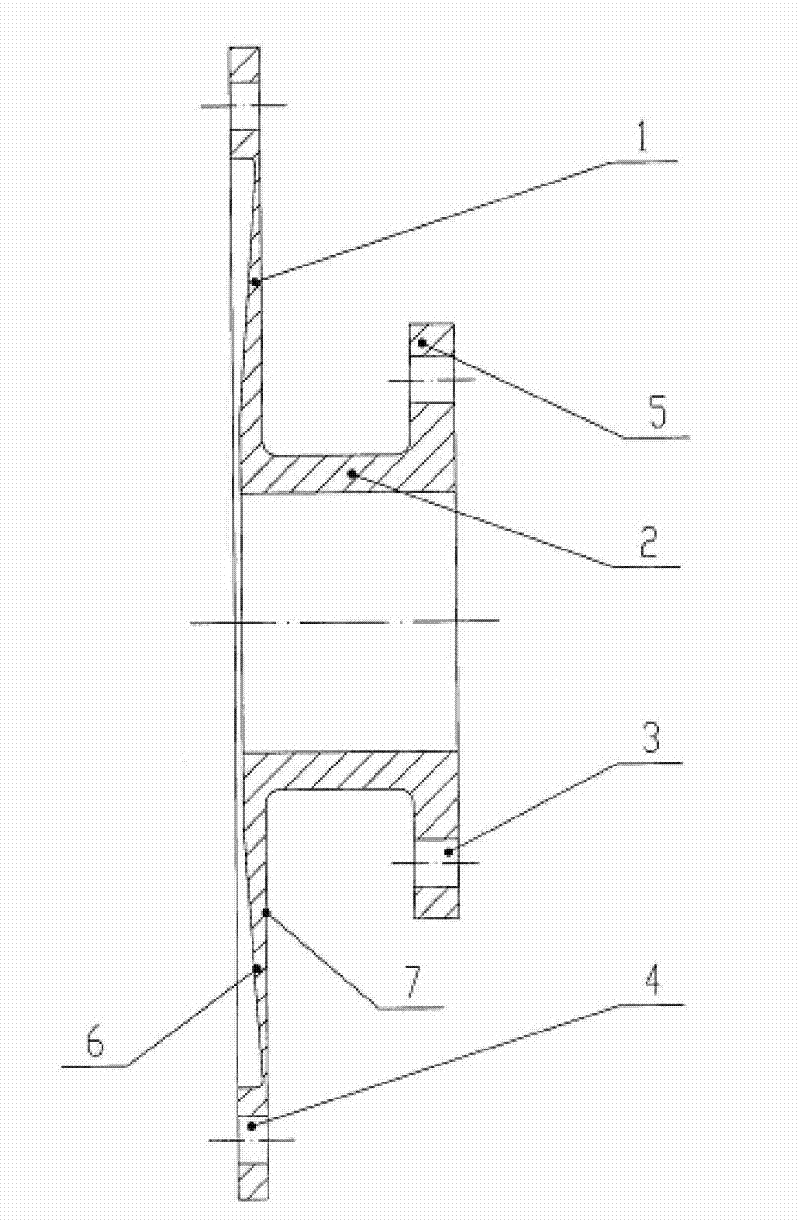

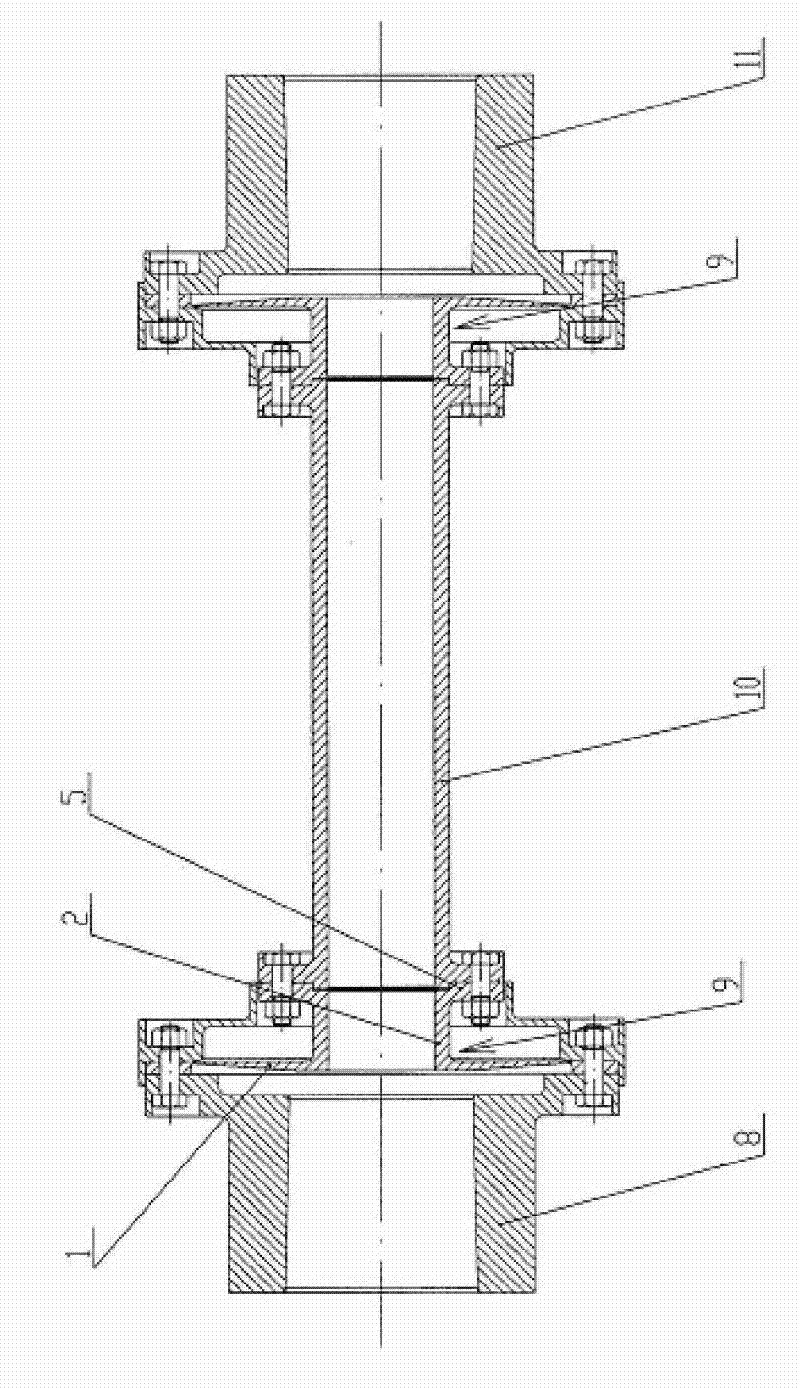

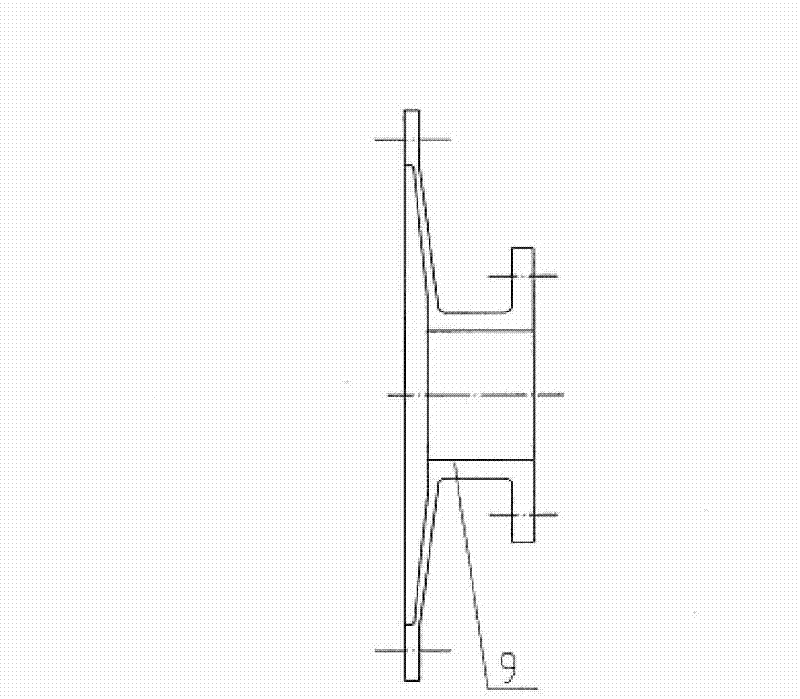

[0022] Such as figure 1 As shown, the transmission diaphragm disc of the present invention mainly includes the transmission diaphragm disc surface area 1, the transmission diaphragm disc connection transition area 2, the transmission diaphragm disc connection hole I3, the transmission diaphragm disc connection hole II4, the diaphragm flange 5, etc., and the specific structure is as follows:

[0023] The transmission diaphragm disc is a sleeve-shaped transmission diaphragm disc connected to the transition area (cylindrical) 2. One end is provided with a transmission diaphragm disc surface area 1, and the other end is provided with a diaphragm flange 5. The integral structure is formed. The edge of 1 has a transmission diaphragm connection hole II4, and the transmission diaphragm flange 5 has a transmission diaphragm connection hole I3.

[0024] In the present invention, the transmission diaphragm disc adopts a single-membrane disc single-curved surface structure, that is, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com