Construction waste treatment device for civil engineering

A construction waste and processing device technology, applied in the direction of manufacturing tools, auxiliary molding equipment, ceramic molding machines, etc., can solve the problems of less shaking, heavy quality, and large suction, and achieve increased stability, improved quality, and improved adhesion force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

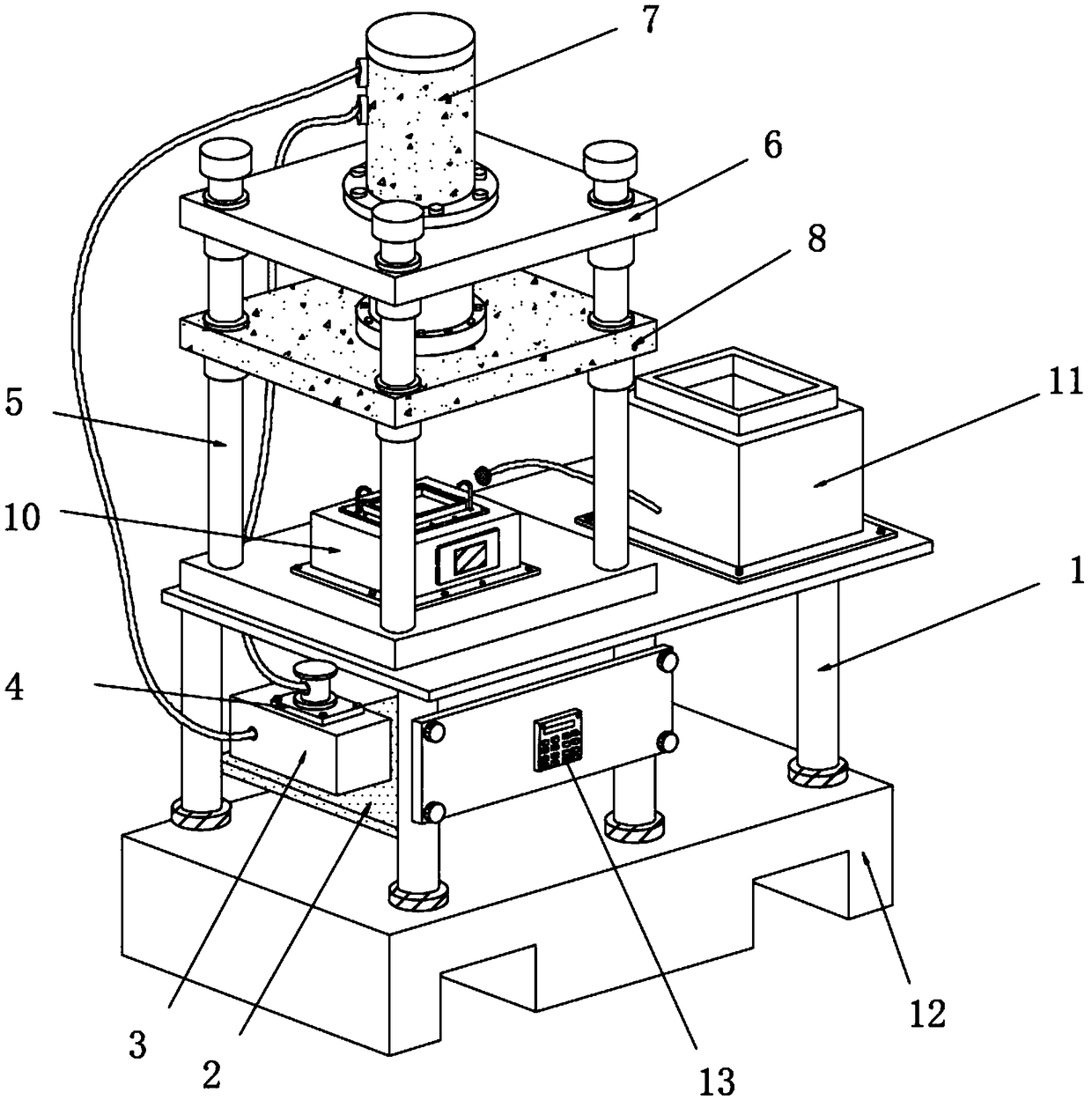

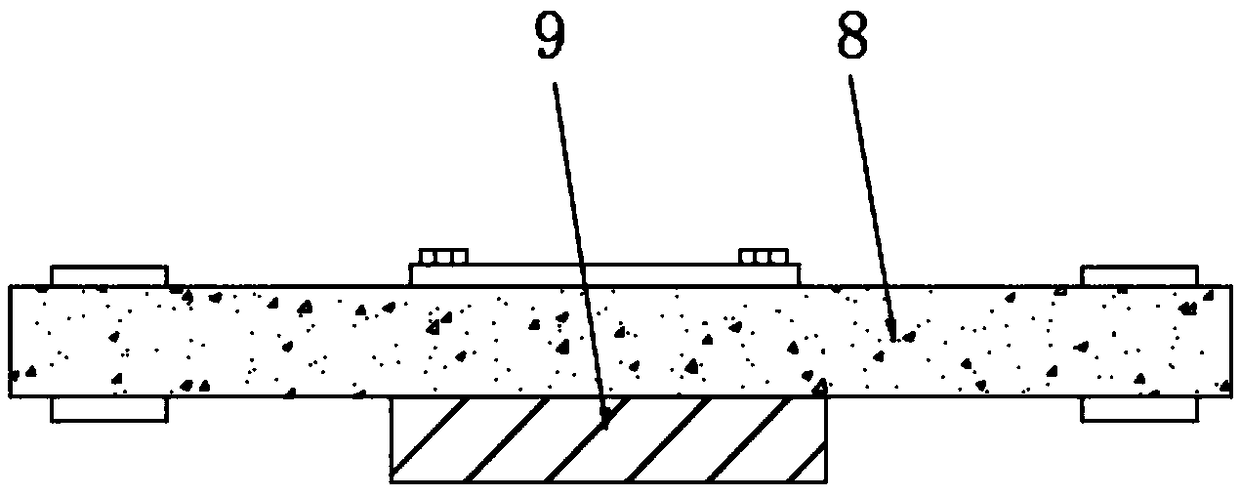

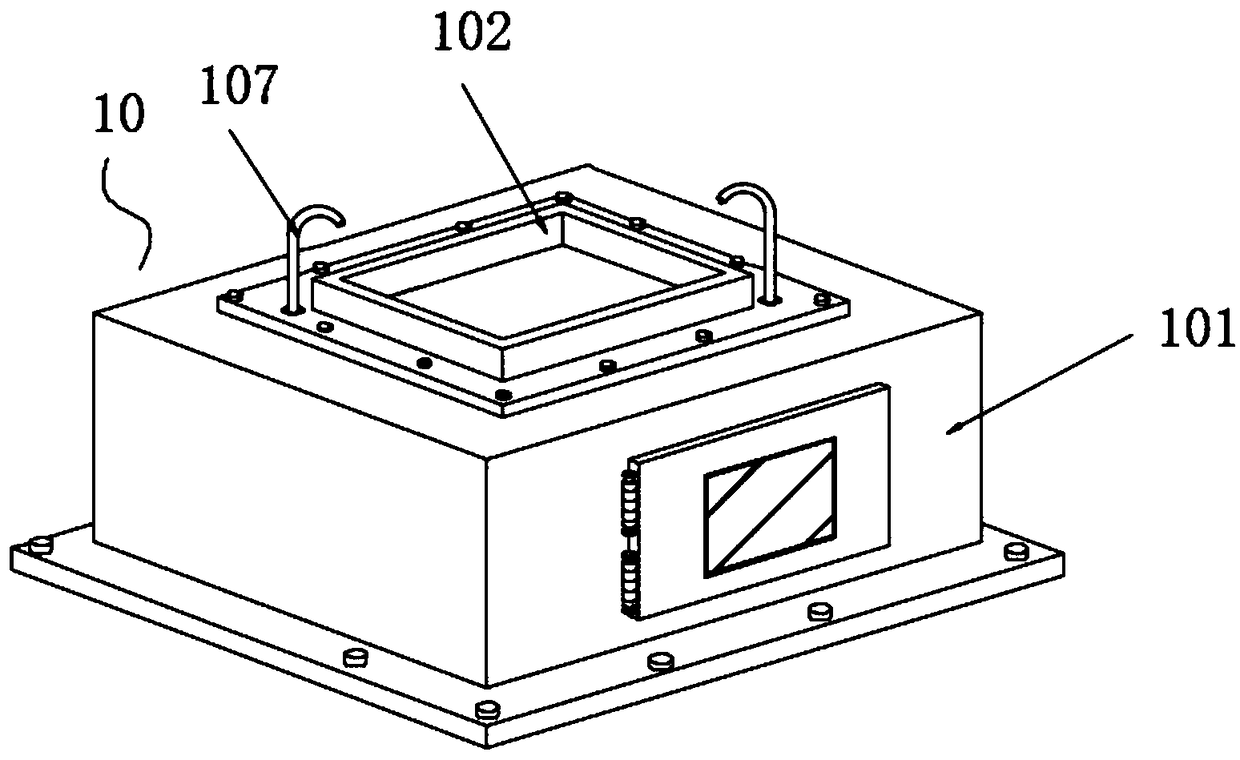

[0027] see Figure 1-7 , in the embodiment of the present invention,

[0028] see Figure 1~2 , a construction waste treatment device for civil engineering, comprising a working platform 1, a pressure-bearing platform 2 is fixedly installed at the bottom of the inner side of the four supporting legs of the working platform 1, and a pressure-bearing platform 2 is fixedly installed on the upper surface of the pressure-bearing platform 2 for storing hydraulic pressure. An oil storage tank 3, the upper surface of the oil storage tank 3 is fixedly equipped with an oil pump 4, and the upper surface of the working platform 1 is fixedly installed with a guide rail 5. There are four guide rails 5 arranged in a rectangular distribution. The upper end of the guide rail 5 is fixed outside the sleeve Connected with a fixed plate 6, the upper surface of the fixed plate 6 is fixedly installed with a hydraulic jack 7, the liquid outlet of the oil storage tank 3 is connected with the liquid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com