Preparation method of gamma-aminobutyric acid green tea

A technology of GABA green tea and tea leaves, which is applied in the field of γ-aminobutyric acid green tea preparation, can solve the problems of marketing restrictions, bad smell, etc., and achieve the effects of simplified process, low caffeine content, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

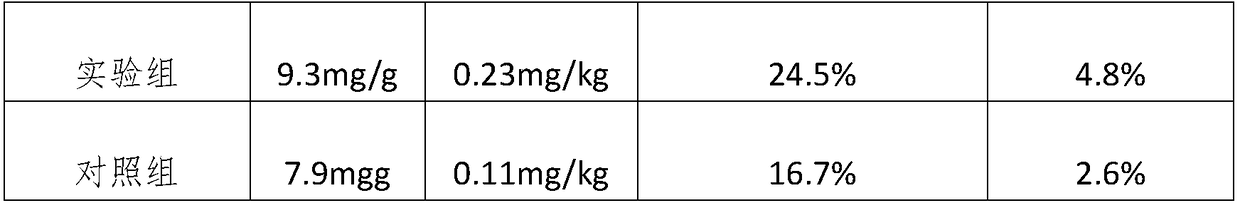

Examples

Embodiment 1

[0025] A preparation method of gamma-aminobutyric acid green tea, comprising the following steps:

[0026] (1) Raw material handling:

[0027] Clean the freshly picked tea leaves, put them in a cold storage at 4°C for 30 minutes, lower the temperature of the cold storage to -20°C at a cooling rate of 2°C / min, keep them in cold storage for 2 hours, then raise the temperature to -5°C, and keep them in cold storage for 4 hours. spare;

[0028] (2) mixing:

[0029] Mix the prepared tea leaves with the nutritional enhancer at a mass ratio of 5:1, place them under the vacuum condition of -0.03mpa for anaerobic treatment for 2 hours, put them into a conventional electric pulverizer and pulverize them to obtain ordinary powder, and then add the ordinary powder into the vibration formula In an ultrafine pulverizer, pulverize at 5° C. for 30 minutes to obtain ultrafine powder.

[0030] The preparation method of the nutritional enhancer is as follows: according to the mass ratio of 1:...

Embodiment 2

[0032] A preparation method of gamma-aminobutyric acid green tea, comprising the following steps:

[0033] (1) Raw material handling:

[0034] Clean the freshly picked tea leaves, put them in a cold storage at 8°C for 40 minutes, lower the temperature of the cold storage to -25°C at a cooling rate of 2°C / min, keep them in cold storage for 3 hours, then raise the temperature to 0°C, and keep them in cold storage for 5 hours. ;

[0035] (2) mixing:

[0036] Mix the prepared tea leaves with the nutritional enhancer at a mass ratio of 5:1, place them under the vacuum condition of -0.06mpa for anaerobic treatment for 5 hours, put them into a conventional electric pulverizer and pulverize them to obtain ordinary powder, and then add the ordinary powder into the vibration formula In an ultrafine pulverizer, pulverize at 12° C. for 50 minutes to obtain ultrafine powder.

[0037] The preparation method of the nutritional enhancer is as follows: according to the mass ratio of 1:3:5, ...

Embodiment 3

[0039] A preparation method of gamma-aminobutyric acid green tea, comprising the following steps:

[0040] (1) Raw material handling:

[0041] Clean the freshly picked tea leaves, put them in a cold storage at 7°C for 35 minutes, lower the temperature of the cold storage to -23°C at a cooling rate of 2°C / min, keep them in cold storage for 2 hours, then raise the temperature to -3°C, and keep them in cold storage for 4 hours. spare;

[0042] (2) mixing:

[0043] Mix the prepared tea leaves with the nutritional enhancer at a mass ratio of 5:1, place them under the vacuum condition of -0.04mpa for anaerobic treatment for 3 hours, put them into a conventional electric pulverizer and pulverize them to obtain ordinary powder, and then add the ordinary powder into the vibration formula In an ultrafine pulverizer, pulverize at 6° C. for 40 minutes to obtain ultrafine powder.

[0044] The preparation method of the nutritional enhancer is as follows: according to the mass ratio of 1:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com