A method for improving the filling capacity of a deep trench

A technology with filling ability and deep grooves, which is applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as early filling sealing, impact on device electrical performance and reliability, and insufficient filling, so as to reduce the difficulty of filling , to achieve the effect of completeness and convenient filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

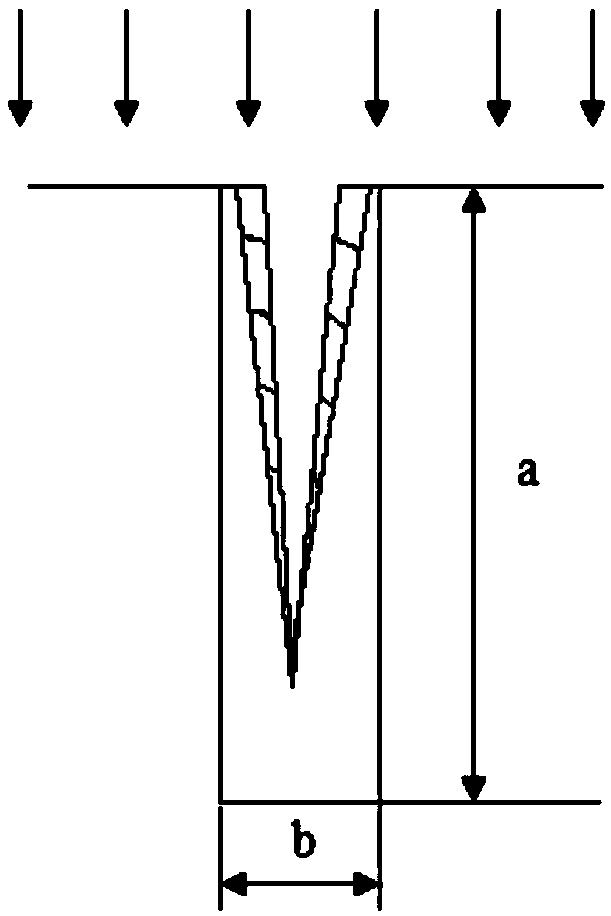

[0019] combine Figure 6 As shown, the method for improving deep trench filling capability, in the following examples, the implementation process is as follows:

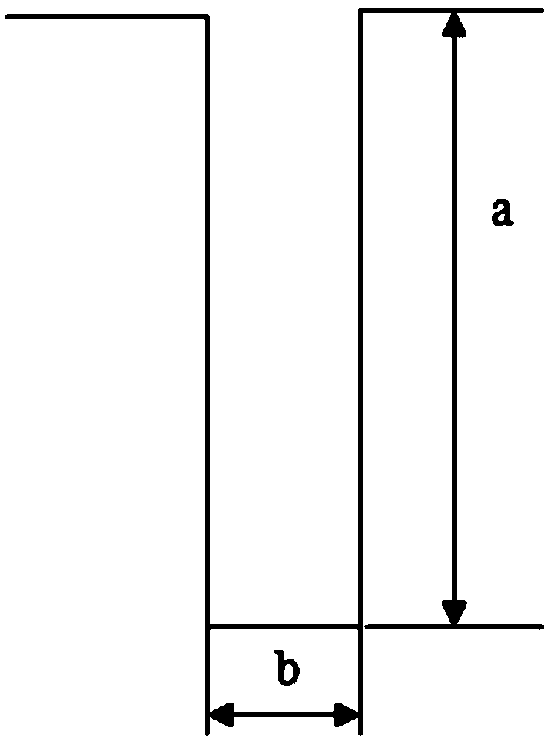

[0020] Step 1. In figure 1 The already formed deep trenches are filled as shown. The deep trench refers to a deep trench with an aspect ratio greater than 5:1. A in the figure represents the height of the deep groove (ie, the depth of the groove), and b represents the width of the deep groove.

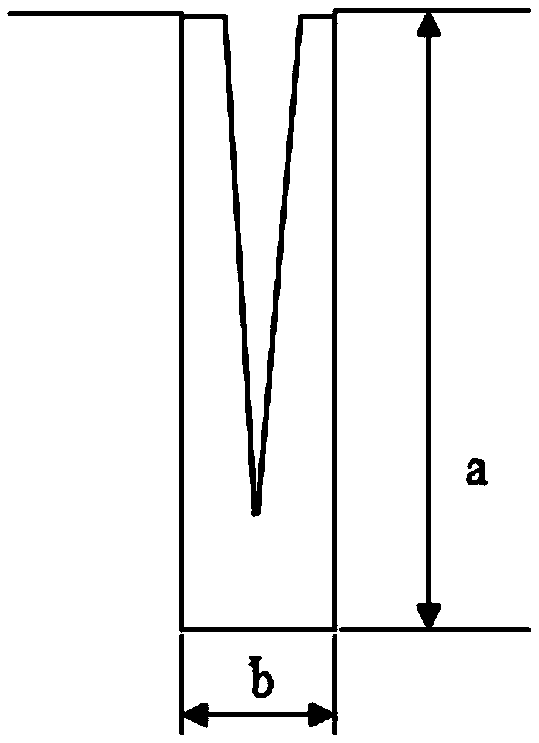

[0021] Step 2. Stop filling when the deep trench is filled to about half of the required time. The deep trench filling described above is only aimed at the length and width structure of the trench, and does not limit the material and filling material of the trench. It can be a silicon trench, or a trench of other materials used in semiconductor processing, and the filling material is also the material used in the normal filling process, such as epitaxy, polysilicon, etc. The stop time on the way is about half of the time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com