A TiO2 and CuO composite porous material for a supercapacitor and a preparation method thereof

A technology of supercapacitors and porous materials, applied in the field of TiO2 and CuO composite porous materials and their preparation, can solve the problems of instability of element ions, damage to mesoporous structure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

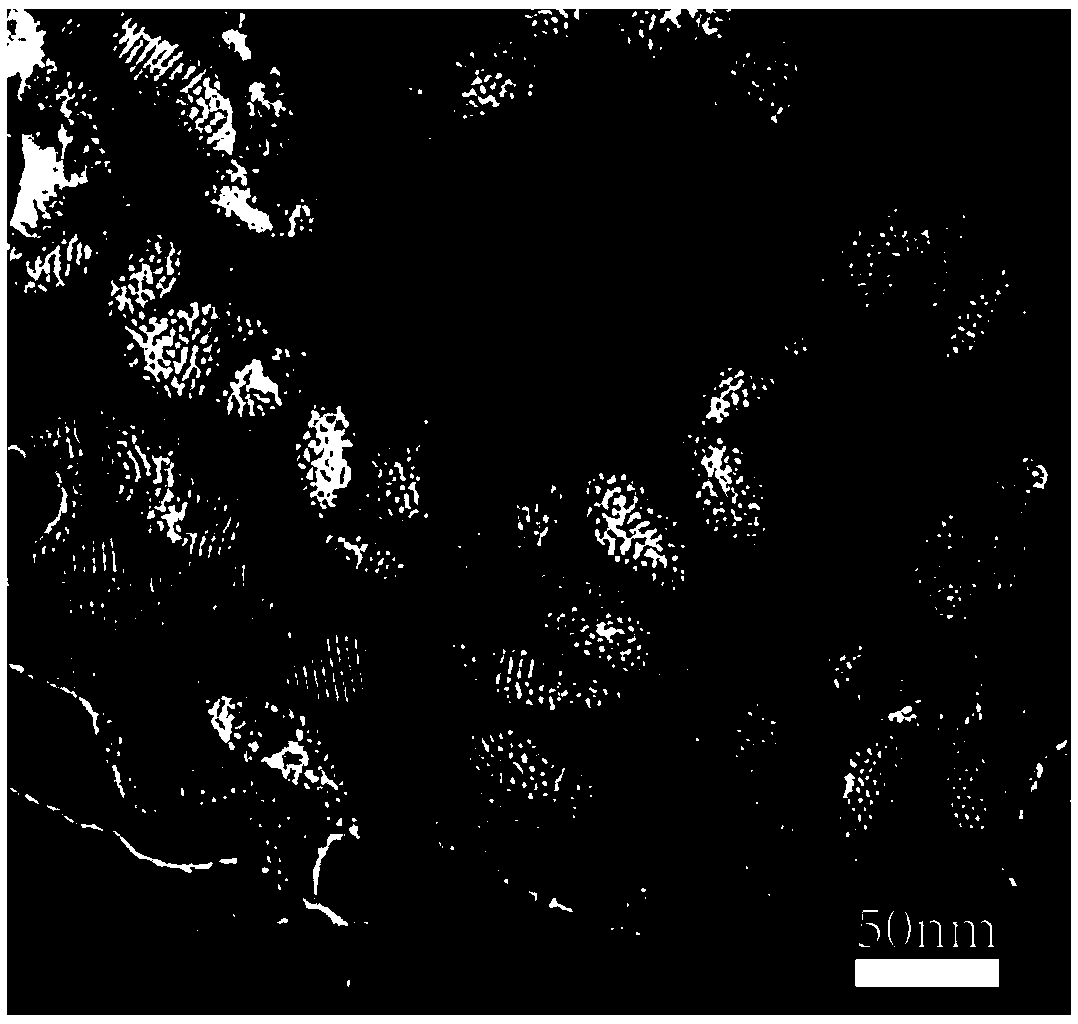

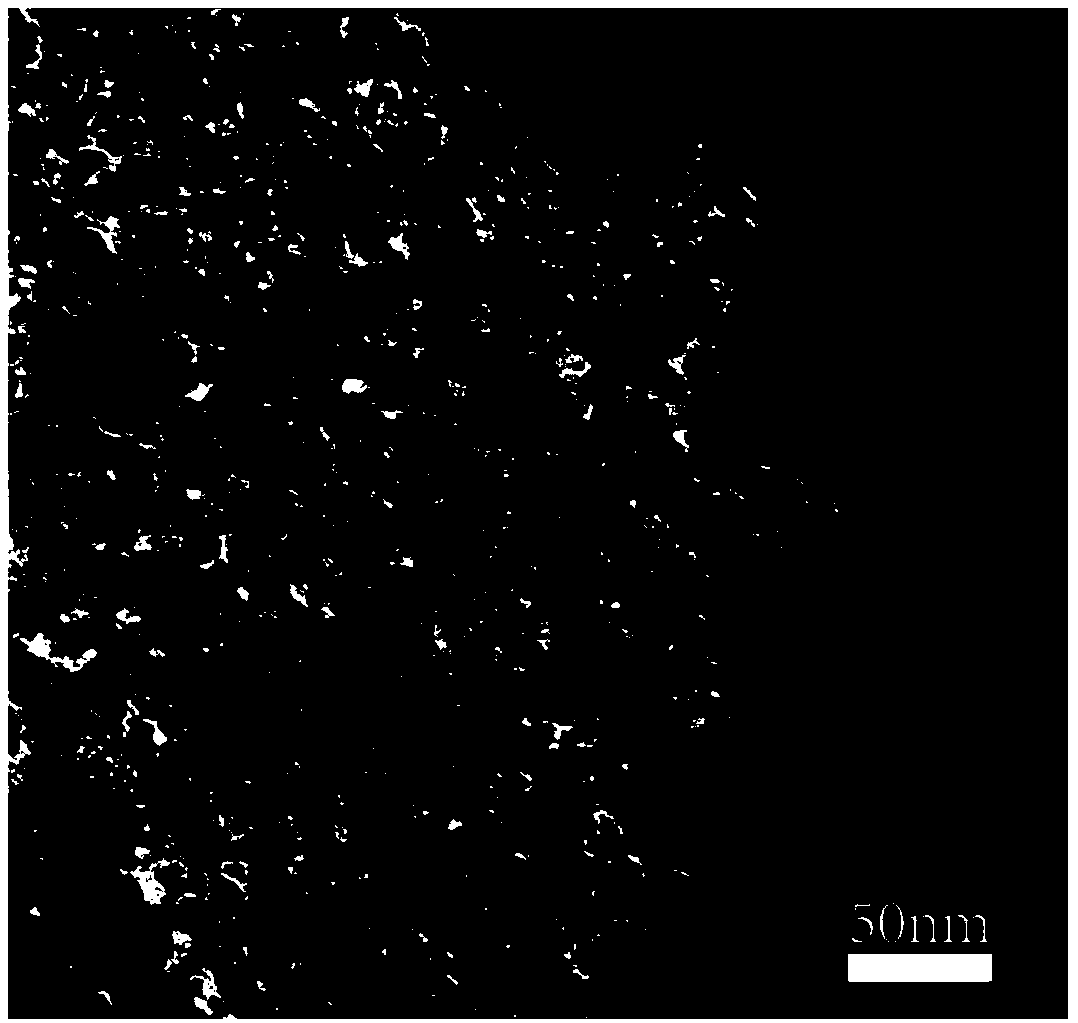

[0026] The embodiment of the present invention provides a kind of TiO2 for supercapacitor 2 and the preparation method of CuO composite porous material, comprises the following steps:

[0027] S1: The glass slide is placed in an ethanol solution of polystyrene microspheres, and the ethanol solvent is evaporated so that the polystyrene microspheres self-assemble on the surface of the glass slide to form a polystyrene film.

[0028] The polystyrene microspheres in this step are macroporous templates, and the polystyrene microspheres are arranged in an orderly manner on the surface of the glass slide through self-assembly induced by solvent evaporation to obtain a polystyrene film.

[0029] S2: Add P123 into ethanol solvent and stir to dissolve. After P123 is dissolved, add isopropyl titanate and hydrochloric acid to stir and mix, add titanium tetrachloride drop by drop and continue to stir and mix, then add copper chloride dihydrate to stir and dissolve to obtain titanium dioxid...

Embodiment 1

[0042] (1) Take 10 mL of polystyrene microsphere aqueous solution with a concentration of 0.2 g / mL, mix it with 10 mL of ethanol, and ultrasonically disperse the polystyrene microspheres for 5 min in a water bath at room temperature to obtain an ethanol solution of polystyrene microspheres, wherein , the particle size of the polystyrene microspheres is 120nm; the glass slide is placed in the ethanol solution of the obtained polystyrene microspheres, and the ethanol solvent is evaporated in a blast oven at 55° C. The surface of the glass slide self-assembled to form a polystyrene film with a thickness of 10 μm. After the polystyrene film was formed, it was kept at 80° C. for 1 hour, and then cooled naturally to room temperature.

[0043] (2) Add 1g of P123 into 10mL of ethanol solvent and stir to dissolve. After P123 is dissolved, add 0.2g of isopropyl titanate and 1mL of hydrochloric acid and stir to mix. Add 0.2mL of titanium tetrachloride drop by drop and continue to stir and...

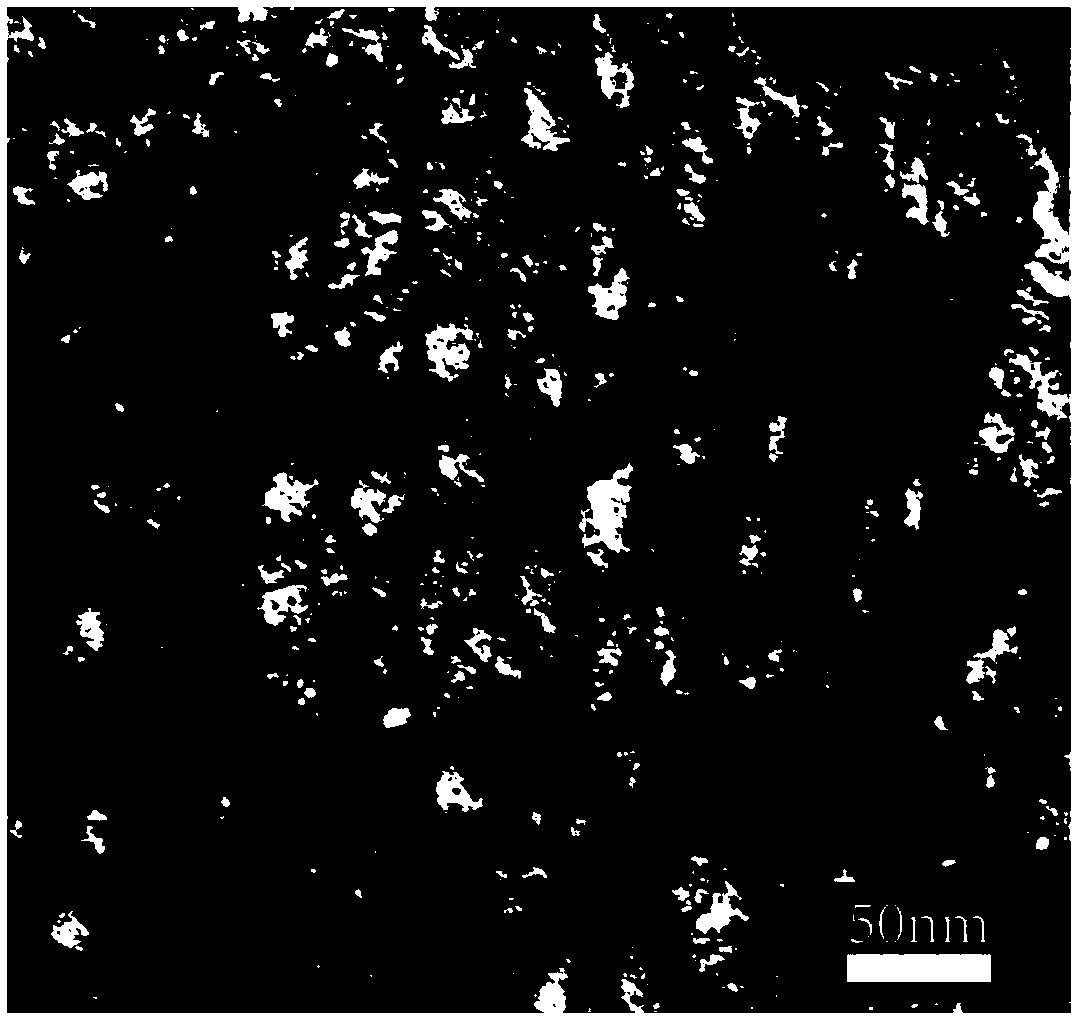

Embodiment 2

[0047] (1) Take 10 mL of polystyrene microsphere aqueous solution with a concentration of 1.5 g / mL, mix it with 10 mL of ethanol, and ultrasonically disperse the polystyrene microspheres in a water bath at room temperature for 5 minutes to obtain an ethanol solution of polystyrene microspheres, wherein , the particle size of the polystyrene microspheres is 460nm; the glass slide is placed in the ethanol solution of the obtained polystyrene microspheres, and the ethanol solvent is evaporated in a blast oven at 55° C. The surface of the glass slide self-assembled to form a polystyrene film with a thickness of 10 μm. After the polystyrene film was formed, it was kept at 80° C. for 1 hour, and then cooled naturally to room temperature.

[0048] (2) Add 3g of P123 into 10mL of ethanol solvent and stir to dissolve. After P123 is dissolved, add 1g of isopropyl titanate and 5mL of hydrochloric acid and stir to mix. Add 2mL of titanium tetrachloride drop by drop and continue to stir and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com