Thermal treatment method for improving performance of aluminum alloy and welding connector thereof

A heat treatment method and welding joint technology, applied in the field of aluminum alloy heat treatment, can solve the problems of joint fracture, reduce the mechanical properties of welded joints, etc., and achieve the effects of improving corrosion resistance, improving resistance to intergranular corrosion, and improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

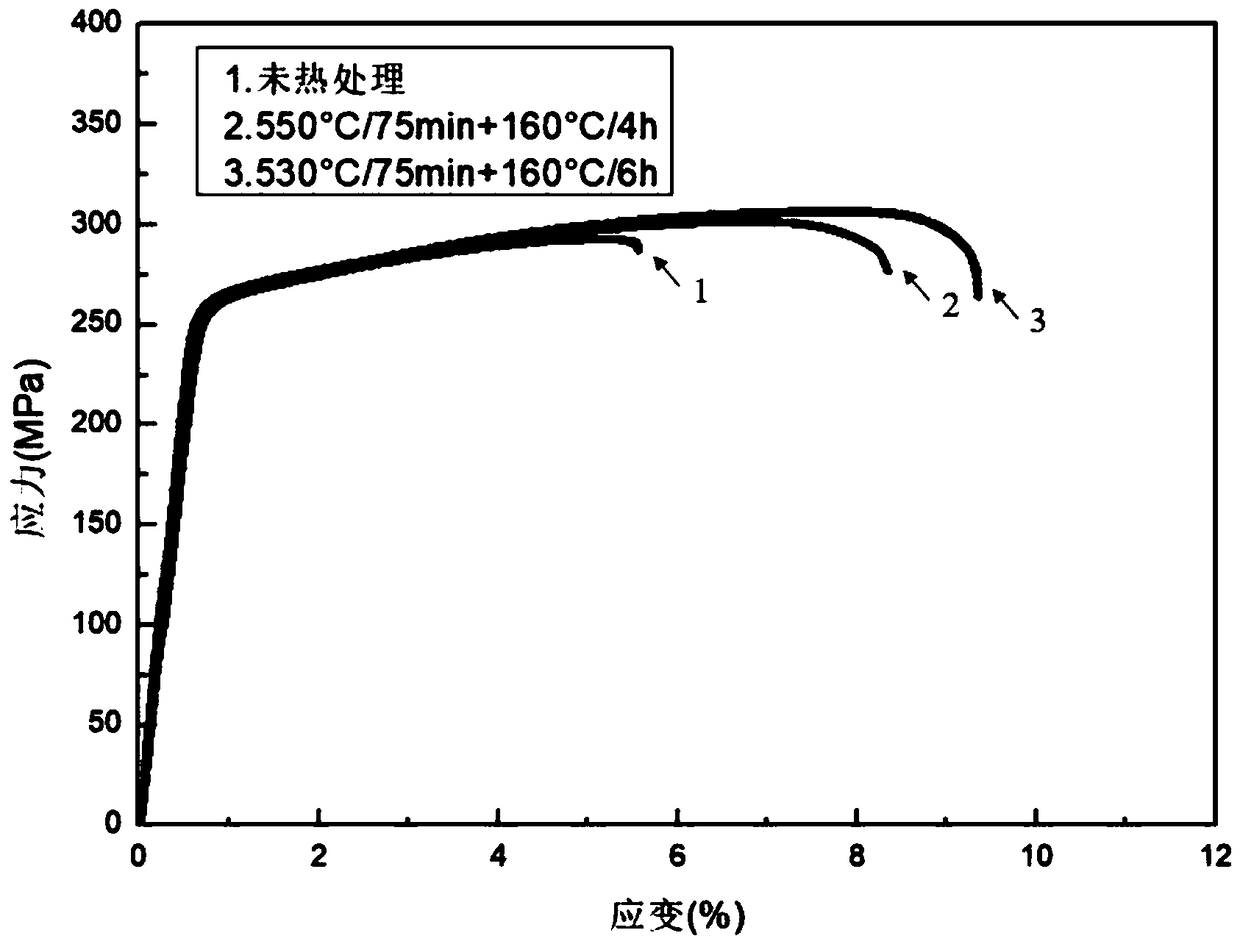

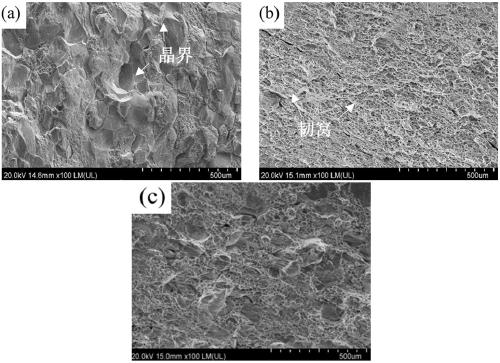

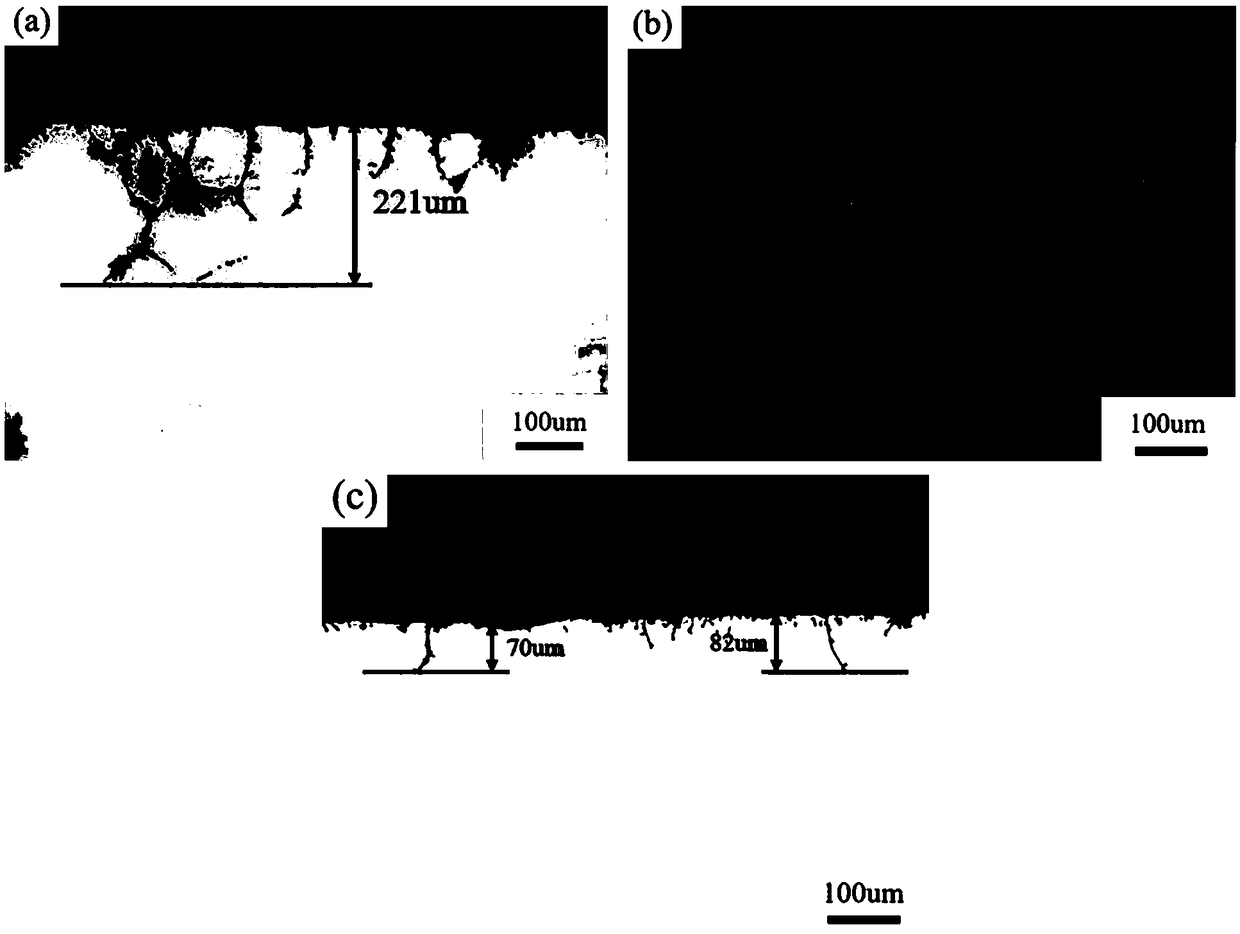

[0029] A heat treatment method for improving the properties of an aluminum alloy, the aluminum alloy described in this example is an A6N01S-T5 aluminum alloy profile with a thickness of 2-4mm; the heat treatment method includes: performing solid solution treatment on the A6N01S-T5 aluminum alloy profile in sequence , water quenching and aging treatment,

[0030] The specific method of the solution treatment is: set the furnace temperature to 550°C, first heat it to 450°C at a heating rate of 10°C / min and keep it for 15 minutes, then heat it to 550°C at a heating rate of 5°C / min, and wait for The temperature of the furnace is stabilized at 550°C. Put the A6N01S-T5 aluminum alloy profile into the furnace for solution treatment for 75 minutes; then take it out immediately, put it in water for quenching; then immediately put it into the furnace for aging heat treatment, the aging treatment temperature is 160°C, the aging treatment time is 4h; take it out and place it in the air to...

Embodiment 2

[0032] A heat treatment method for improving the properties of an aluminum alloy, the aluminum alloy described in this example is an A6N01S-T5 aluminum alloy profile with a thickness of 2-4mm; the heat treatment method includes: performing solid solution treatment on the A6N01S-T5 aluminum alloy profile in sequence , water quenching and aging treatment,

[0033] The specific method of the solution treatment is: set the furnace temperature to 530°C, first heat it to 450°C at a heating rate of 10°C / min and keep it for 15 minutes, then heat it to 530°C at a heating rate of 5°C / min, and wait for The temperature of the furnace is stabilized at 530°C. Put the A6N01S-T5 aluminum alloy profile into the furnace for solution treatment for 75 minutes; then take it out immediately and put it in water for quenching; then immediately put it into the furnace for aging heat treatment. The aging treatment temperature is 160°C, the aging treatment time is 6h; take it out and place it in the air...

Embodiment 3

[0039] A heat treatment method for improving the properties of an aluminum alloy, comprising sequentially performing solution treatment, water quenching and aging treatment on the aluminum alloy, the aluminum alloy described in this example is 6N01 aluminum alloy; the specific method of the solution treatment is: setting a furnace The temperature is 530°C, first heated to 450°C at a heating rate of 10°C / min and kept for 15 minutes, and then heated to 530°C at a heating rate of 5°C / min. Put it into the furnace for solution treatment for 90 minutes; then take it out immediately, put it into water for quenching; then put it into the furnace immediately for aging heat treatment, the aging treatment temperature is 155 ° C, and the aging treatment time is 10 hours; take it out and place it in the air Air cool to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com