High chromium alloy steel crucible for magnesium smelting and preparation method thereof

A technology for smelting alloy steel and magnesium, which is applied in the field of high-chromium alloy steel crucibles for magnesium smelting and its preparation, and can solve problems such as complex processes, affecting the related performance of magnesium and magnesium alloy products, and poor high-temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

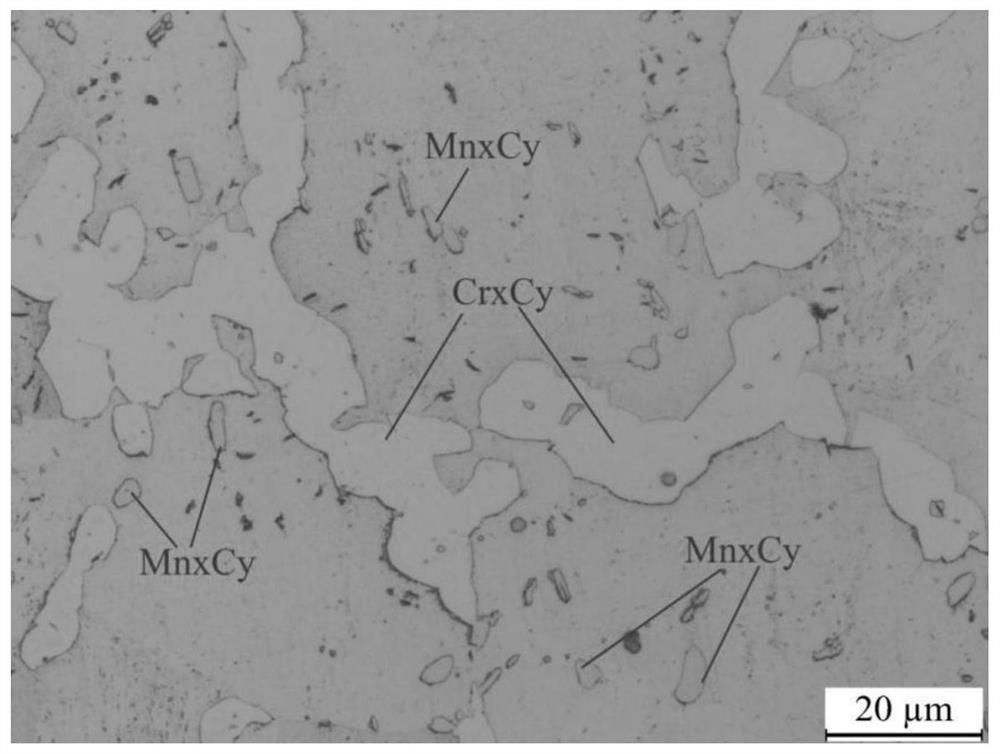

Image

Examples

preparation example Construction

[0018] A method for preparing a high-chromium alloy steel crucible for magnesium smelting. Steel scrap is added to an intermediate frequency induction furnace, and after melting, raw materials such as pig iron, Co block, ferrosilicon, ferromanganese, and low-carbon ferrochrome are added in order to obtain a crucible whose composition meets the requirements. High chromium alloy steel, for purification, the purification temperature is 1520~1560℃, argon gas is blown into the bottom of the ladle, the duration is 0.5~2.0 minutes, the pressure is 2.0×10 4 ~5.0×10 4 MPa, after the argon blowing is completed, the pouring temperature of the molten steel is not lower than 1480°C, the impurities are discharged, and the crucible is made by integral casting by the lost foam casting process.

[0019] The service life of the steel is relatively high, the room temperature hardness of the obtained steel is greater than 59.6HRC, and the high temperature strength at 900°C is above 380MPa.

[00...

Embodiment 1

[0023] The ingredients are weighed according to the target composition, and the weighed steel scrap is added to the intermediate frequency induction furnace. After melting, an appropriate amount of pig iron, Co block, ferrosilicon, ferromanganese, and low-carbon ferrochrome are added in sequence for purification. The purification temperature is 1520°C , argon gas was blown into the bottom of the ladle, the duration was 2.0 minutes, and the pressure was 5.0×10 4 MPa, pouring temperature is 1480°C, impurities are discharged in the form of slag, sampling analysis and adjustment of alloy composition (weight percentage) to contain C: 0.52, Si: 1.71, Mn: 3.98, Cr: 18.74, Co: 0.8, the rest is iron, After the alloy composition meets the requirements, the finished crucible is cast as a whole by the lost foam casting process.

[0024] According to the test, the high temperature strength of the crucible is 416MPa at 900°C, and the service life can reach 88 days, which is about 60% higher...

Embodiment 2

[0026] The ingredients are weighed according to the target composition, and the weighed steel scrap is added to the intermediate frequency induction furnace. After melting, an appropriate amount of pig iron, Co block, ferrosilicon, ferromanganese, and low-carbon ferrochrome are added in turn for purification. The purification temperature is 1530°C , argon gas was blown into the bottom of the ladle for 1.5 minutes at a pressure of 4.0×10 4 MPa, pouring temperature is 1490°C, impurities are discharged in the form of slag, sampling analysis and adjustment of alloy composition (weight percentage) to contain C: 0.6, Si: 2.1, Mn: 4.18, Cr: 20.53, Co: 0.95, the rest is iron, After the alloy composition meets the requirements, the finished crucible is cast as a whole by the lost foam casting process.

[0027] According to the test, the high temperature strength of the crucible is 403MPa at 900°C, and the service life can reach 82 days, which is about 50% higher than that of the butt w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com