Modified ZSM-35 molecular sieve and preparation method thereof

A ZSM-35 and molecular sieve technology, applied in the field of modified ZSM-35 molecular sieve and its preparation, to achieve the effect of improving selectivity and ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Therefore, the preparation method of the modified ZSM-35 molecular sieve provided by the present invention can be understood as a method for improving the secondary pore distribution of the ZSM-35 molecular sieve, which includes:

[0039] Step A, uniformly mixing ZSM-35 molecular sieve powder and alumina powder to obtain a ZSM-35 molecular sieve-alumina mixture;

[0040] Step B, adding a dilute acid solution to the ZSM-35 molecular sieve-alumina mixture for kneading to obtain an acidified ZSM-35 molecular sieve-alumina mixture;

[0041] Step C, adding a pore expander and deionized water to the prepared acidified ZSM-35 molecular sieve-alumina mixture for kneading to obtain a modified ZSM-35 molecular sieve precursor mixture;

[0042] In step D, the prepared catalyst precursor mixture is molded and extruded, then dried and calcined to obtain a modified ZSM-35 molecular sieve.

[0043]According to some embodiments of the present invention, the alumina powder includes one...

Embodiment 1

[0068] (1) Mix 250g ZSM-35 molecular sieve powder with 89.3g pseudo-boehmite (Al 2 o 3 Content is 70%) add in the mixer and mix, after mixing evenly, make ZSM-35 molecular sieve-alumina mixture;

[0069] (2) Add 99.2g dilute hydrochloric acid (HCl content is 6.3%) solution to the ZSM-35 molecular sieve-alumina mixture and knead to prepare the acidified ZSM-35 molecular sieve-alumina mixture;

[0070] (3) Add 15.6 g of cellulose to the prepared acidified ZSM-35 molecular sieve-alumina mixture, then add 39.7 g of deionized water and knead to obtain a modified ZSM-35 molecular sieve precursor mixture;

[0071] (4) Put the prepared modified ZSM-35 molecular sieve precursor mixture into an extruder for molding, dry the formed molecular sieve at 120°C, transfer the dried molecular sieve to a muffle furnace at 450°C Calcined for 4h to prepare modified ZSM-35 molecular sieve.

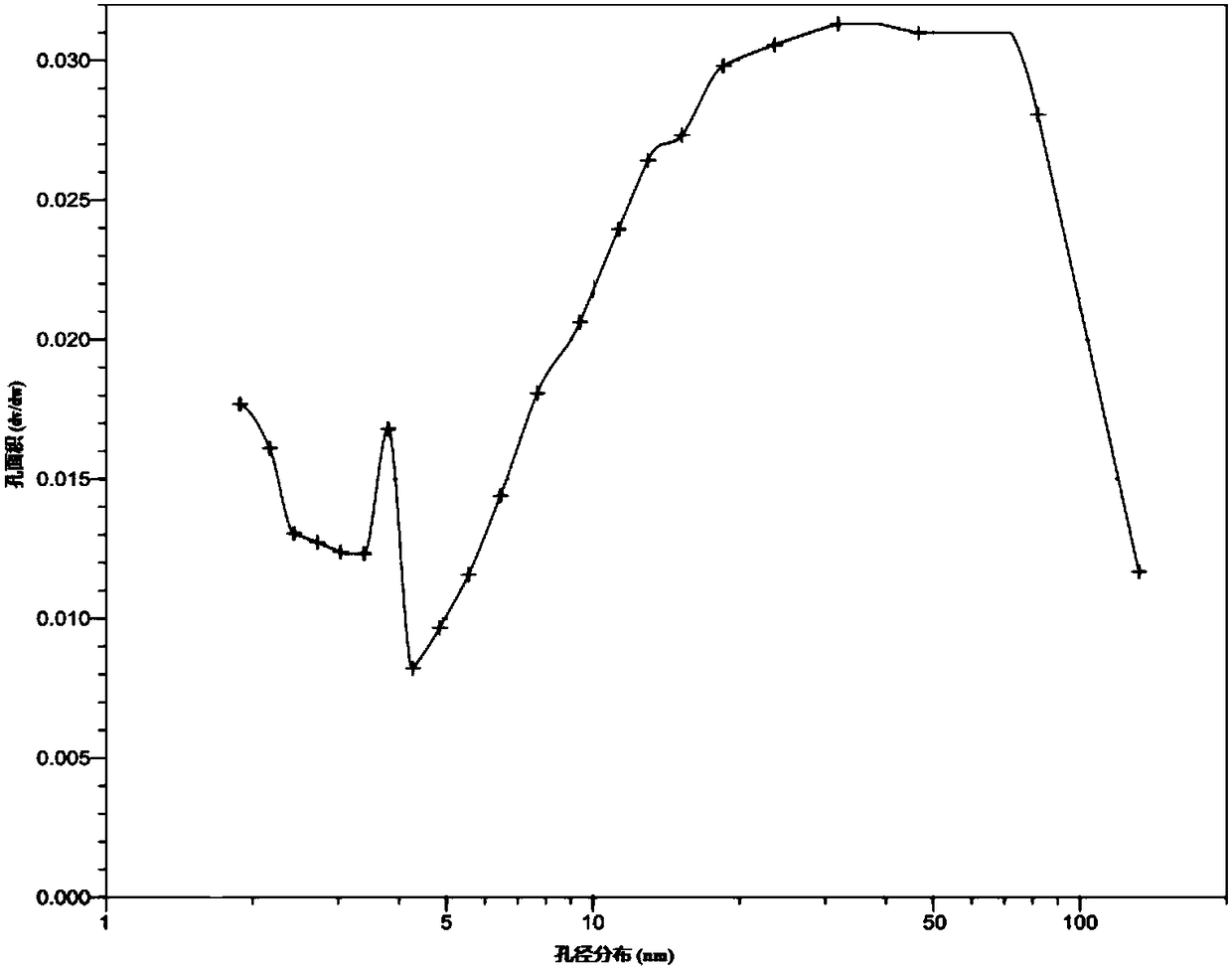

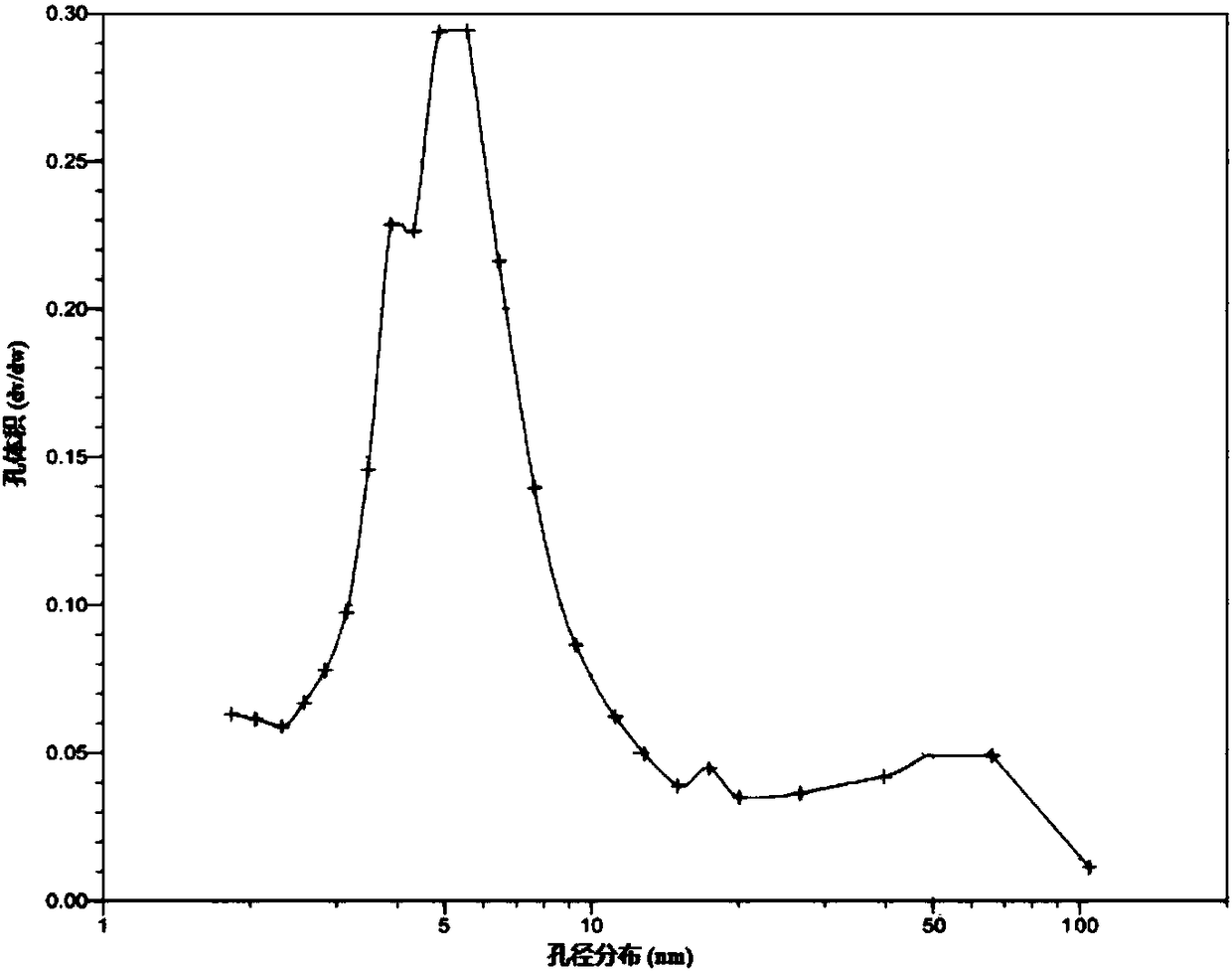

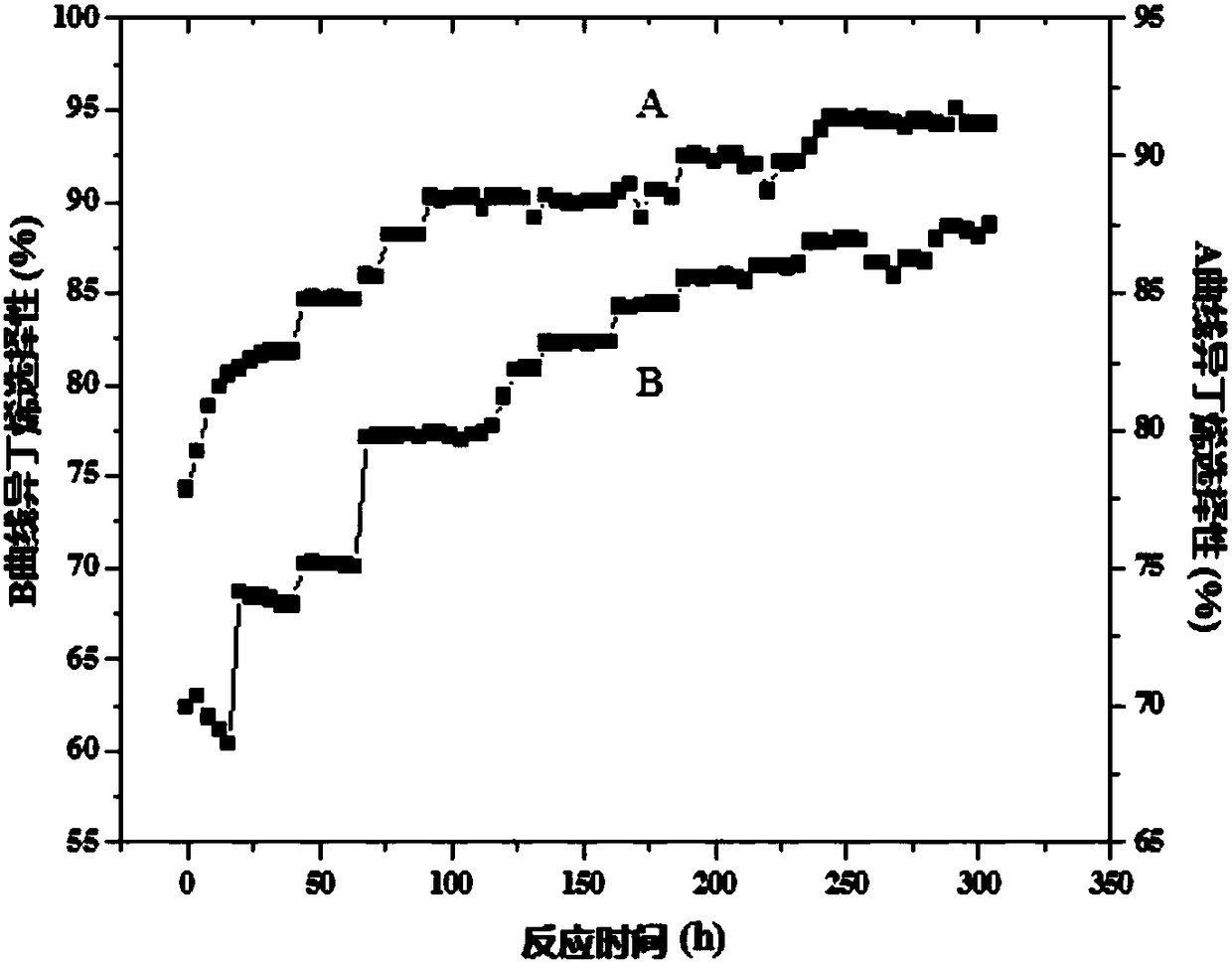

[0072] The prepared modified ZSM-35 molecular sieve was subjected to BET analysis, and the result showed ...

Embodiment 2

[0074] The difference from Example 1 is that the amount of ZSM-35 molecular sieve powder is changed to 300g, the aluminum source is changed to γ-alumina (alumina content 100%), and the consumption is 75g, and the acid is changed to dilute sulfuric acid, and the consumption is 297.6 g, the pore expander was changed to petroleum coke, the dosage was 26.3g, the amount of deionized water was changed to 208.3g, the drying temperature was changed to 110°C, the roasting temperature was changed to 500°C, the roasting time was changed to 10h, and the remaining components and conditions constant.

[0075] The prepared modified ZSM-35 molecular sieve was subjected to BET analysis, and the result showed that the secondary pore diameter of the prepared modified ZSM-35 molecular sieve was concentrated in 3-4nm, and the intensity was 87N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com