Method and device for manufacturing continuous filament reinforced plastic pressure pipe

A technology of reinforced plastics and continuous fibers, which is applied in the direction of tubular articles, other household appliances, household appliances, etc., to achieve the effect of accurate and reliable size, broad market prospects, and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

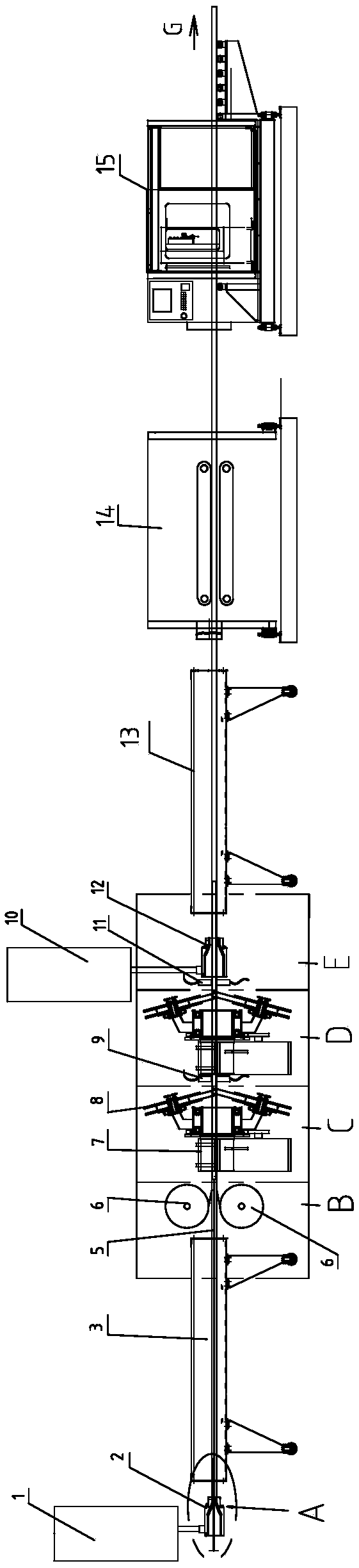

[0039] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

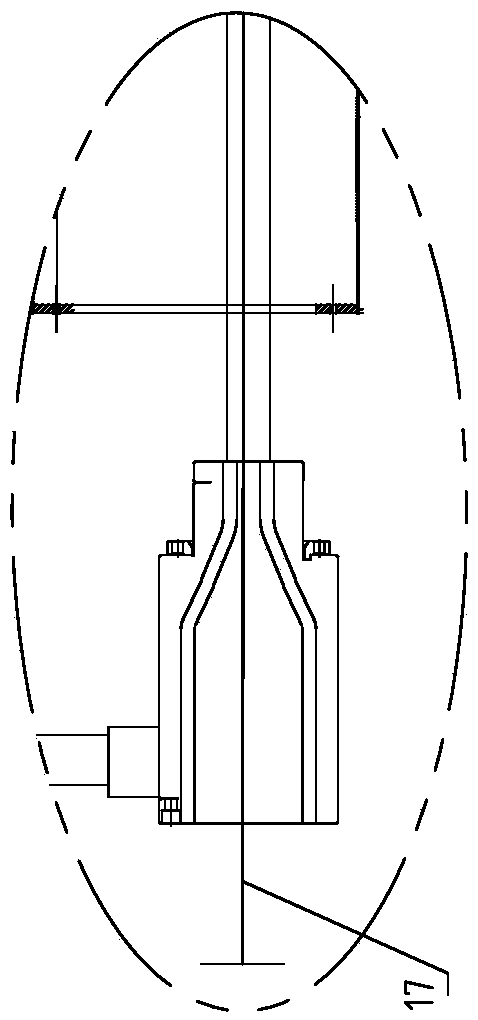

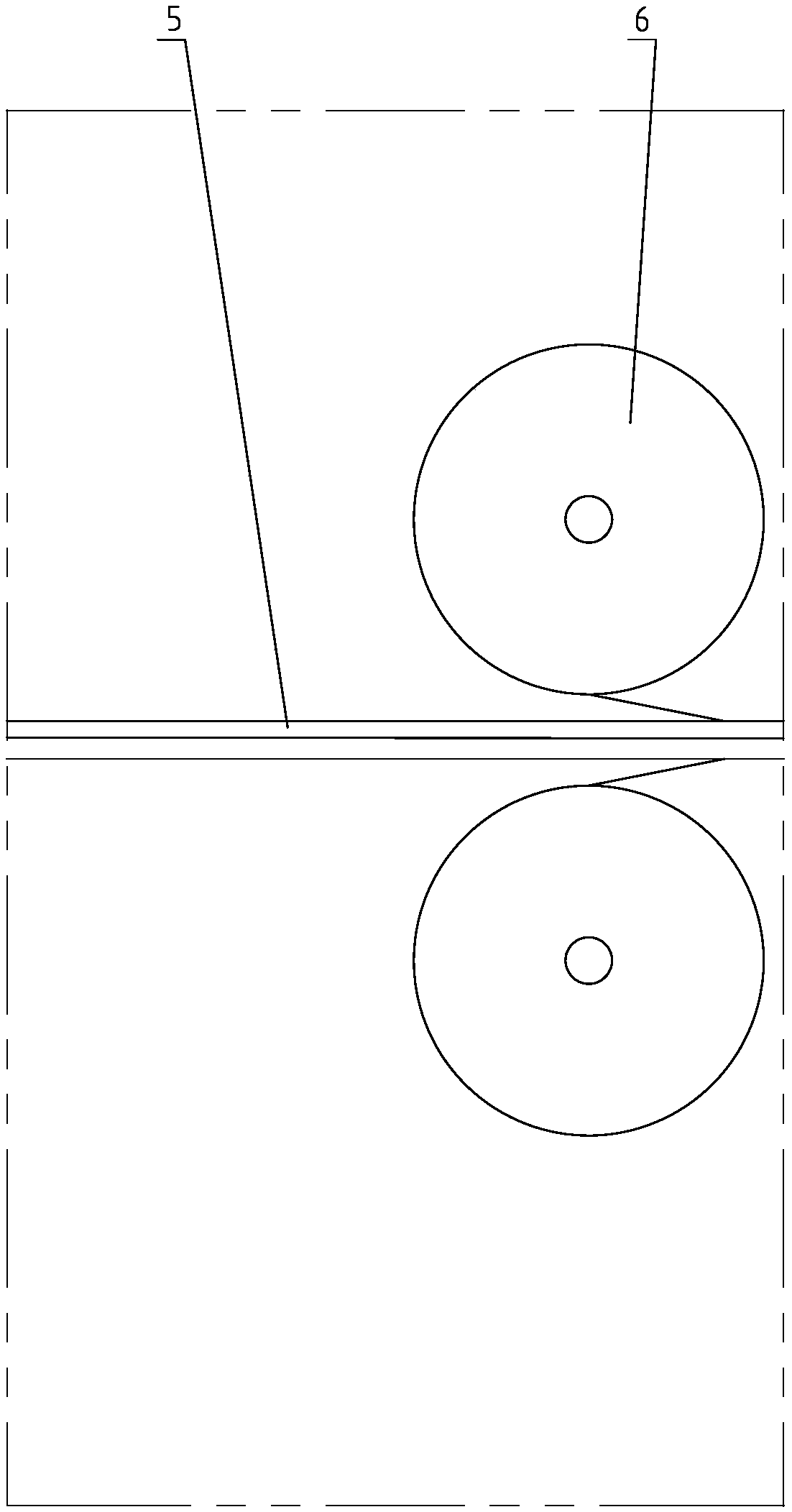

[0040] The cross-section of the continuous fiber reinforced plastic pressure pipe manufactured by the present invention is as Figure 8 As shown, the intermediate reinforcement layer of the pressure pipe is composed of at least one axially stretched pre-impregnated plastic fiber tape 300 (the width and thickness of the pre-impregnated plastic fiber tape are determined according to requirements) and at least one circumferential helical (preferably a helix angle of 40° -89 degrees) coated pre-impregnated plastic fiber tape 200, the two sides of the middle reinforcement layer are the plastic inner wall layer 400 (ie, the inner tube) and the plastic outer wall layer 100 which are connected to the middle reinforcement layer through extrusion molding. The axially stretched pre-impregnated plastic fiber tape directly bears the pulling force during manufacture, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com