Continuous fiber reinforced plastic pressure pipe and manufacturing method and device thereof

A technology of reinforced plastics and continuous fibers, applied in the direction of pipes, rigid pipes, tubular objects, etc., can solve problems such as insurmountable pipe molding, and achieve the effect of overcoming local stretching phenomenon, ensuring stability, and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

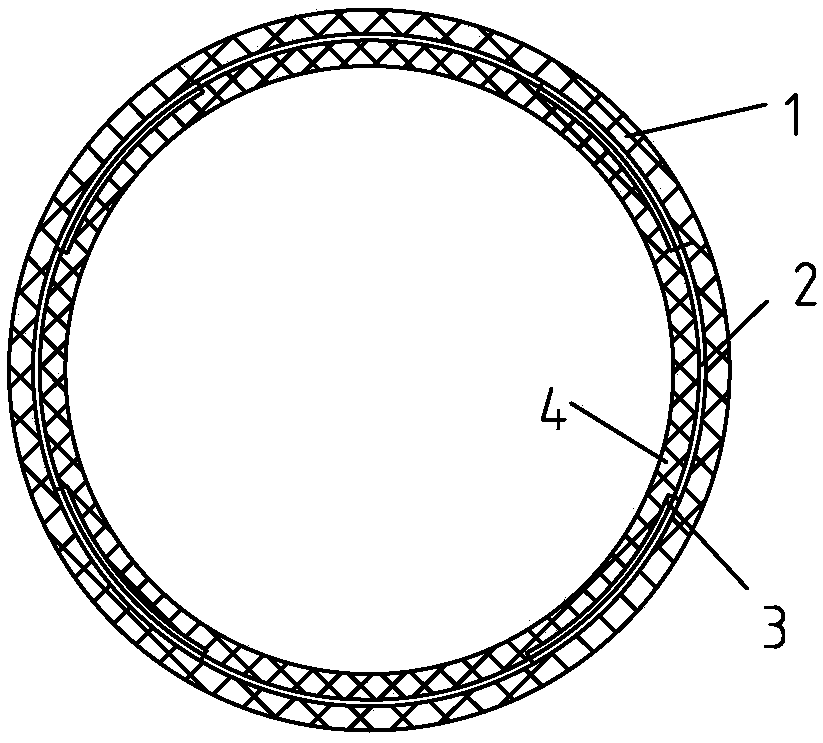

[0047] The continuous fiber-reinforced plastic pressure pipe shown in the accompanying drawings, the middle reinforcement layer of the pressure pipe consists of at least one axially stretched inner prepreg plastic fiber strip 3 and at least one circumferential helical (preferably helix angle is 40-89 degrees) The outer prepreg plastic fiber tape 2 covering the inner prepreg plastic fiber tape is composed of the two sides of the middle reinforcement layer, respectively, the plastic inner wall layer 4 and the plastic outer wall layer 1 which are connected with the middle reinforcement layer through extrusion molding. When the inner prepreg plastic fiber tape is manufactured, it directly bears the pulling force, so that the manufacturing can be carried out continuously.

[0048] In the above structure, the inner prepreg plastic fiber belt can be located on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com