Guide rail block assembly and hot-bending forming device

A guide rail and guide block technology, which is applied in glass forming, glass reshaping, wood bending, etc., can solve problems such as instability, eccentric size, and inapplicability, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The specific implementation of this embodiment is as follows:

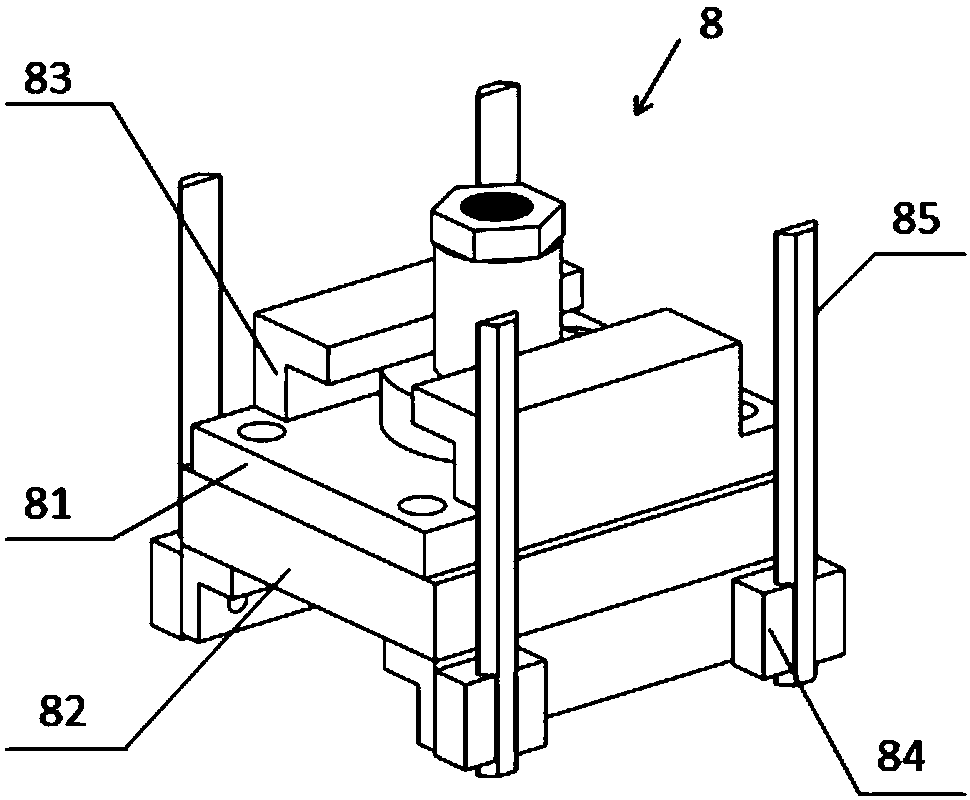

[0041] Such as figure 1 As shown, the rail guide block assembly 8 provided in this embodiment includes a first transition plate 81 and a second transition plate 82 from top to bottom, the first transition plate 81 is fixedly connected to the second transition plate 82, and the first transition plate The upper part of the plate 81 is fixedly provided with a cylinder connector, and on both sides of the second transition plate 82 are provided guide rails 85 and guide blocks 84 matching with the guide rails 85 .

[0042]It should be noted that, in the actual application process, the guide block 84 slides on the predetermined trajectory of the guide rail 85, which can transmit the kinetic energy of the forming cylinder and act on the forming press plate 9 of the upper mold, driving the forming press plate 9 of the upper mold to perform hot bending of the mold forming.

[0043] Preferably, the guide rail 85 is ...

Embodiment 2

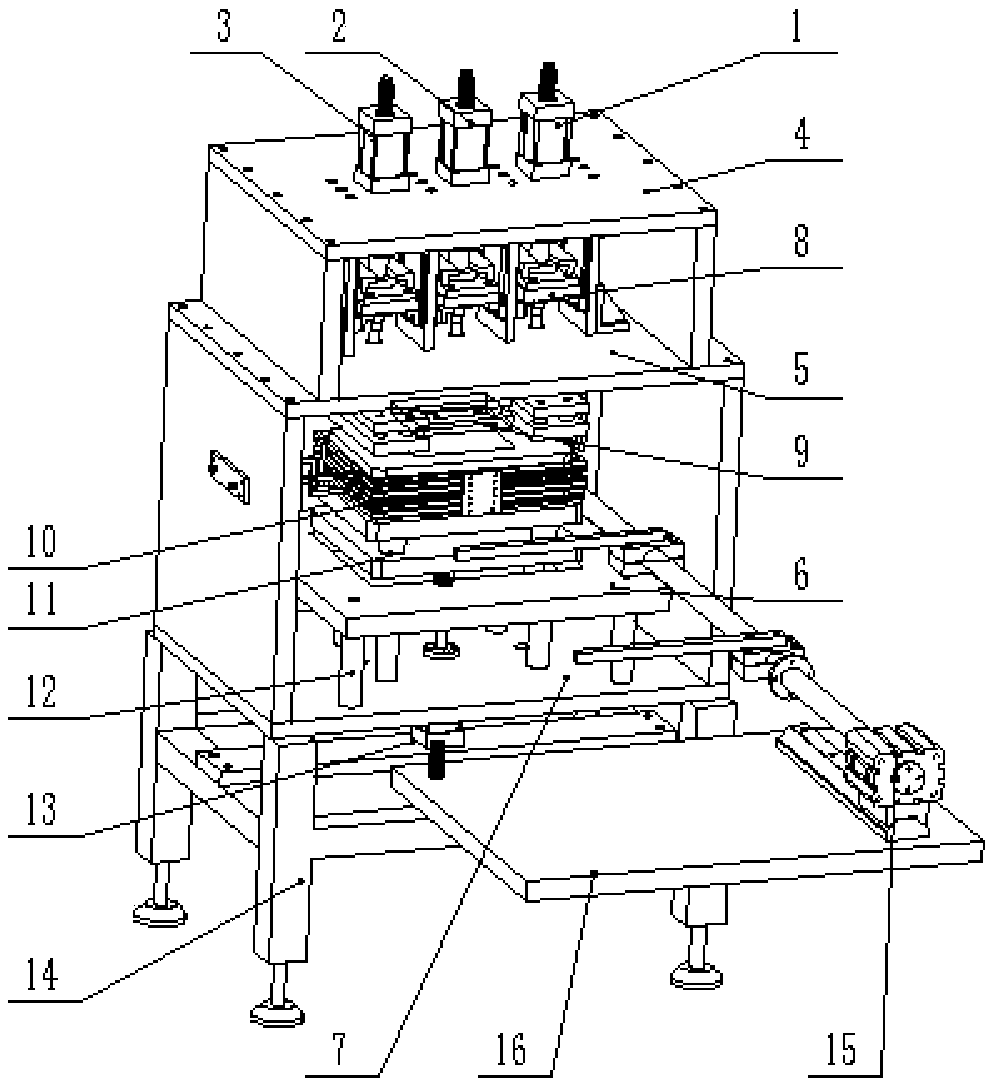

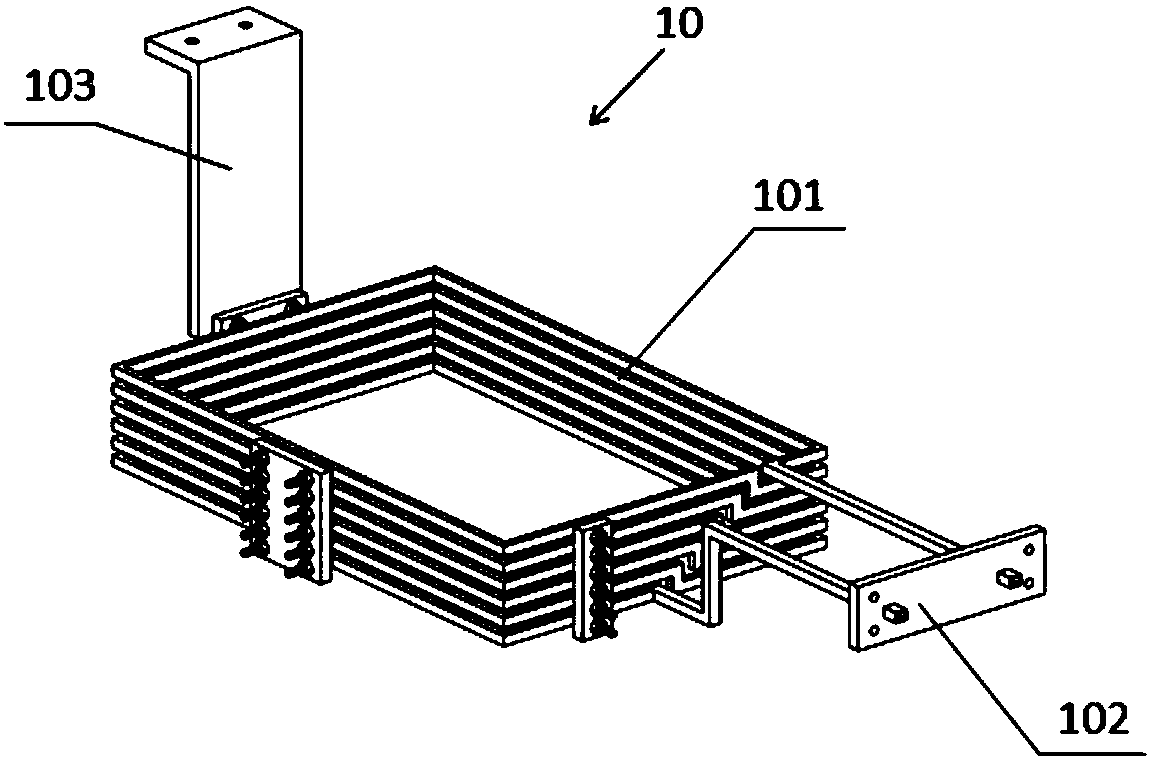

[0048] Such as figure 1 As shown in -5, the hot bending forming device for panel module assembly provided by this embodiment includes three forming cylinders arranged in sequence from top to bottom, the above-mentioned guide rail guide block assembly 8, upper mold forming pressure plate 9, heating copper Ring assembly 10, lower mold positioning plate 11 and the lower mold ejection cylinder 13 for lifting the lower mold positioning plate 11; each molding cylinder is connected with a guide rail guide block assembly 8 respectively, and the bottom of each guide rail guide block assembly 8 is respectively Connect the upper mold forming pressure plate 9; when forming, the inside of the heating copper ring is provided with a mold; each forming cylinder drives a guide rail guide block assembly 8 to perform hot-bending forming on the mold, and first use one of the forming cylinders to press the mold And pressurize the plane area of the product, and then use the other two forming cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com