Forming method of mold base

A molding method and mold base technology, which is applied in the field of mold bases, can solve the problems of bulkiness and high cost, and achieve the effects of reducing human labor, reducing weight, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

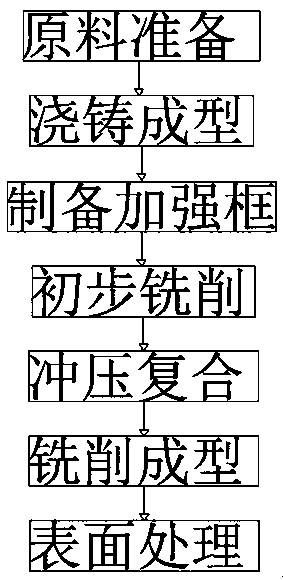

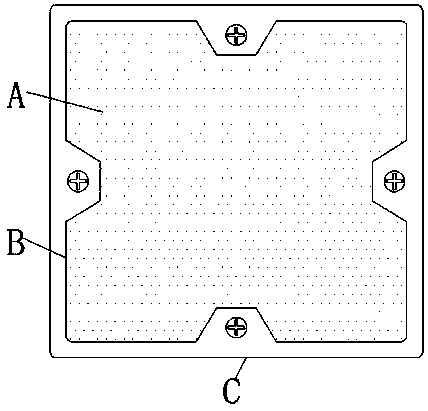

[0022] refer to Figure 1-2 , a molding method of a mold base, comprising the following steps:

[0023] S1: Raw material preparation, according to the raw material formula, mix and stir the raw material according to the proportion, and then put the mixed raw material into the furnace for melting;

[0024] S2: Casting molding, inject the molten metal mixed solution in S1 into the casting mold to form a composite aluminum plate, and then cut the composite aluminum plate into aluminum blocks A with the same volume through a laser cutting machine;

[0025] S3: Preparing a reinforcement frame, forming a reinforcement frame B with a rectangular frame structure by laser cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com