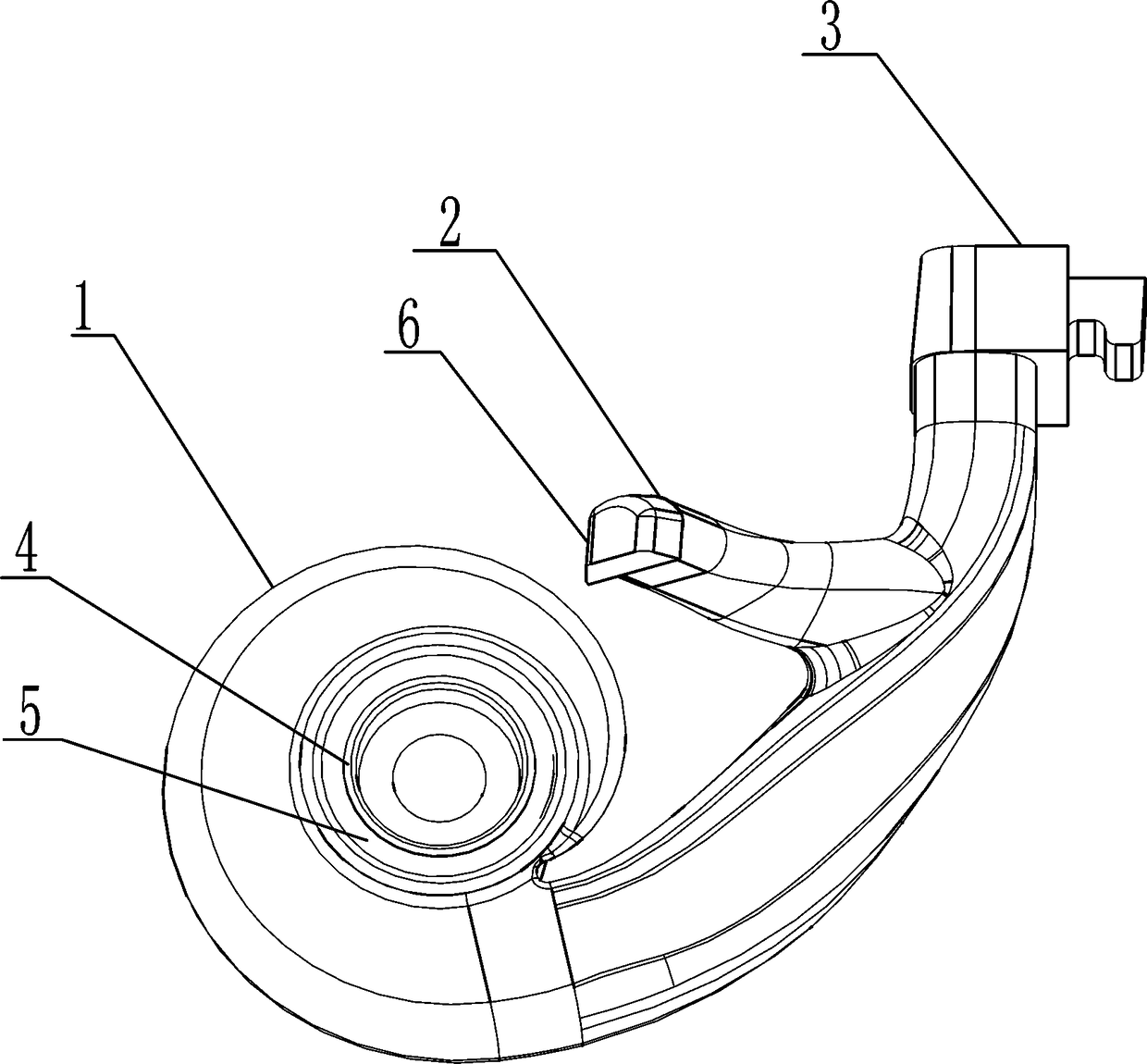

Double-runner sand core of heat-resisting steel spiral case as well as producing method and locating method of sand core

A heat-resistant steel, double-runner technology, used in cores, manufacturing tools, casting and molding equipment, etc., can solve the problems of difficult molding, insufficient sand core, rough surface, etc., achieve high yield, solve pouring choking, surface smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A heat-resistant steel volute double-channel sand core is made of the following raw materials in weight percentage:

[0034] Ceramsite sand 78%, iron ore sand 15%, polyethylene resin 2.5%, calcium stearate 1.5% and curing agent 3.0%.

[0035] The curing agent is formed by mixing urotropine and water in a weight ratio of 1:0.7.

[0036] The particle size of the ceramsite sand is 70 mesh.

[0037] The grain size of described iron ore sand is 70 orders.

[0038] A method for manufacturing the above-mentioned heat-resistant steel volute double-channel sand core, comprising the following steps:

[0039] (1) Sand mixing: mix the above-mentioned raw materials evenly according to the proportion to obtain mixed sand;

[0040] (2) Core box heating: install the static and dynamic core boxes on the core shooter for heating, and heat the dynamic and static core boxes to 230°C and 210°C respectively;

[0041] (3) Sand filling: the mixed sand in step (1) is injected into the step ...

Embodiment 2

[0047] A heat-resistant steel volute double-channel sand core is made of the following raw materials in weight percentage:

[0048] 80% ceramsite sand, 14% iron ore sand, 2.3% polyethylene resin, 1.3% calcium stearate and 2.4% curing agent.

[0049] The curing agent is formed by mixing urotropine and water in a weight ratio of 1:0.6.

[0050] The particle size of the ceramsite sand is 140 mesh.

[0051] The particle size of the described iron ore sand is 90 mesh.

[0052] A method for manufacturing the above-mentioned heat-resistant steel volute double-channel sand core, comprising the following steps:

[0053] (1) Sand mixing: mix the above-mentioned raw materials evenly according to the proportion to obtain mixed sand;

[0054] (2) Core box heating: Install the dynamic and static core boxes on the core shooter for heating, and the dynamic and static core boxes are heated to 240°C and 230°C respectively;

[0055] (3) Sand filling: the mixed sand in step (1) is injected in...

Embodiment 3

[0059]A heat-resistant steel volute double-channel sand core is made of the following raw materials in weight percentage:

[0060] Ceramsite sand 81%, iron ore sand 13%, polyethylene resin 2.5%, calcium stearate 1.3% and curing agent 2.2%.

[0061] The curing agent is formed by mixing urotropine and water in a weight ratio of 1:1.

[0062] The particle size of the ceramsite sand is 90 mesh.

[0063] The particle size of the described iron ore sand is 90 mesh.

[0064] A method for manufacturing the above-mentioned heat-resistant steel volute double-channel sand core, comprising the following steps:

[0065] (1) Sand mixing: mix the above-mentioned raw materials evenly according to the proportion to obtain mixed sand;

[0066] (2) Core box heating: Install the static and dynamic core boxes on the core shooter for heating, and heat the dynamic and static core boxes to 240°C and 220°C respectively;

[0067] (3) Sand filling: the mixed sand in step (1) is injected into the ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com