FeSe-based amorphous film catalyst and preparation method and application thereof

An amorphous thin film and catalyst technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of high instability of iron-based thin films, poor control of components, etc., to achieve The effect of uniform distribution of film components, good oxygen evolution catalytic performance, high relaxation and diffusion capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Fe in this example 40 co 40 Se 20 The structural formula of the amorphous thin film catalyst according to the atomic percentage of each element is: Fe 40 co 40 Se 20 , the preparation steps are as follows:

[0021] Step 1. According to Fe 40 co 40 Se 20 The atomic ratio required by the general formula of the alloy composition is to use Fe powder, Co powder and Se powder as raw materials (the purity of each raw material is ≥99.9wt.%) to make an alloy target (ordered at Beijing Zhongnuo New Materials).

[0022] Step 2. After cleaning and drying the alloy target material obtained in step 1 with absolute ethanol, place it on the target head in the chamber of the vacuum magnetron sputtering coating machine.

[0023] In order to meet the requirements of different tests for substrates, three substrates, carbon paper, glass sheet and silver foil, were taken, cleaned with acetone and absolute ethanol, and pasted on the substrate of a vacuum magnetron sputtering coating m...

Embodiment 2

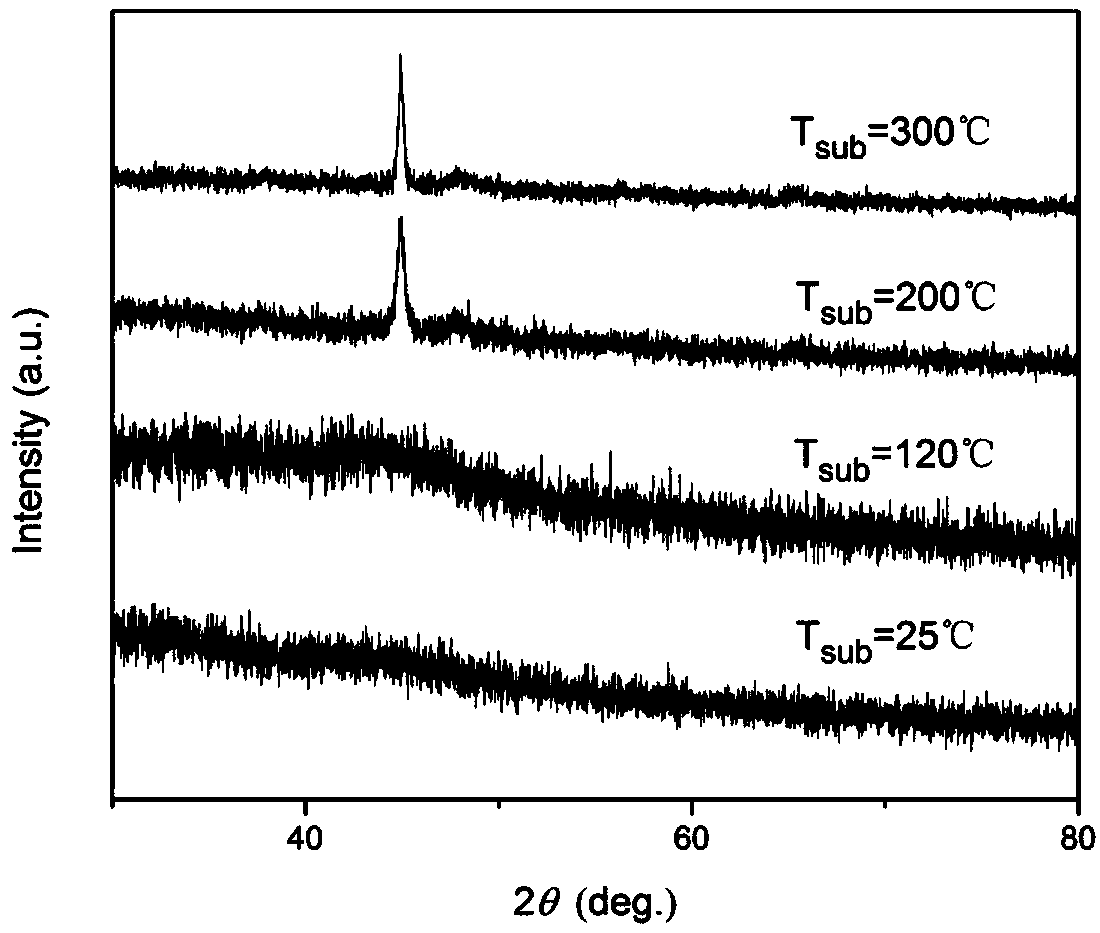

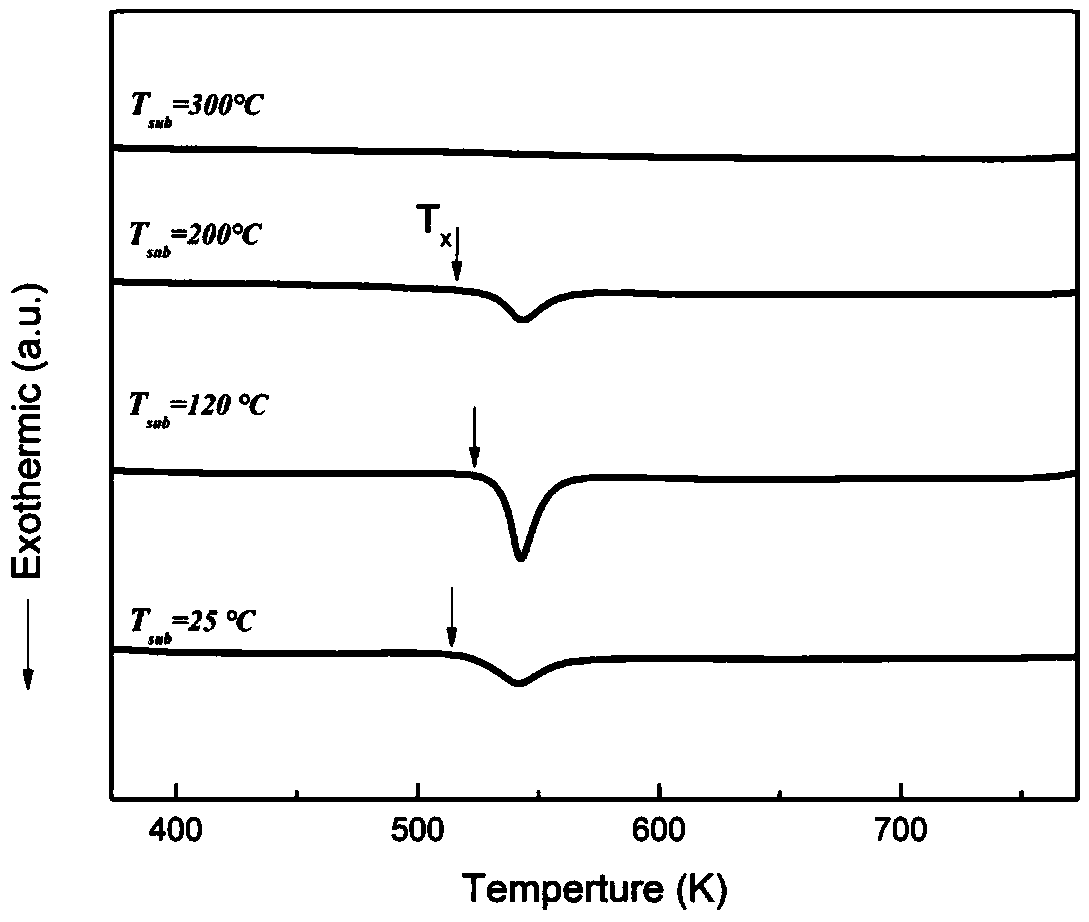

[0032] This embodiment prepares Fe in the same manner as in Example 1 40 co 40 Se 20 For amorphous thin film catalysts, the only difference is that the temperature in step 4 is 25°C.

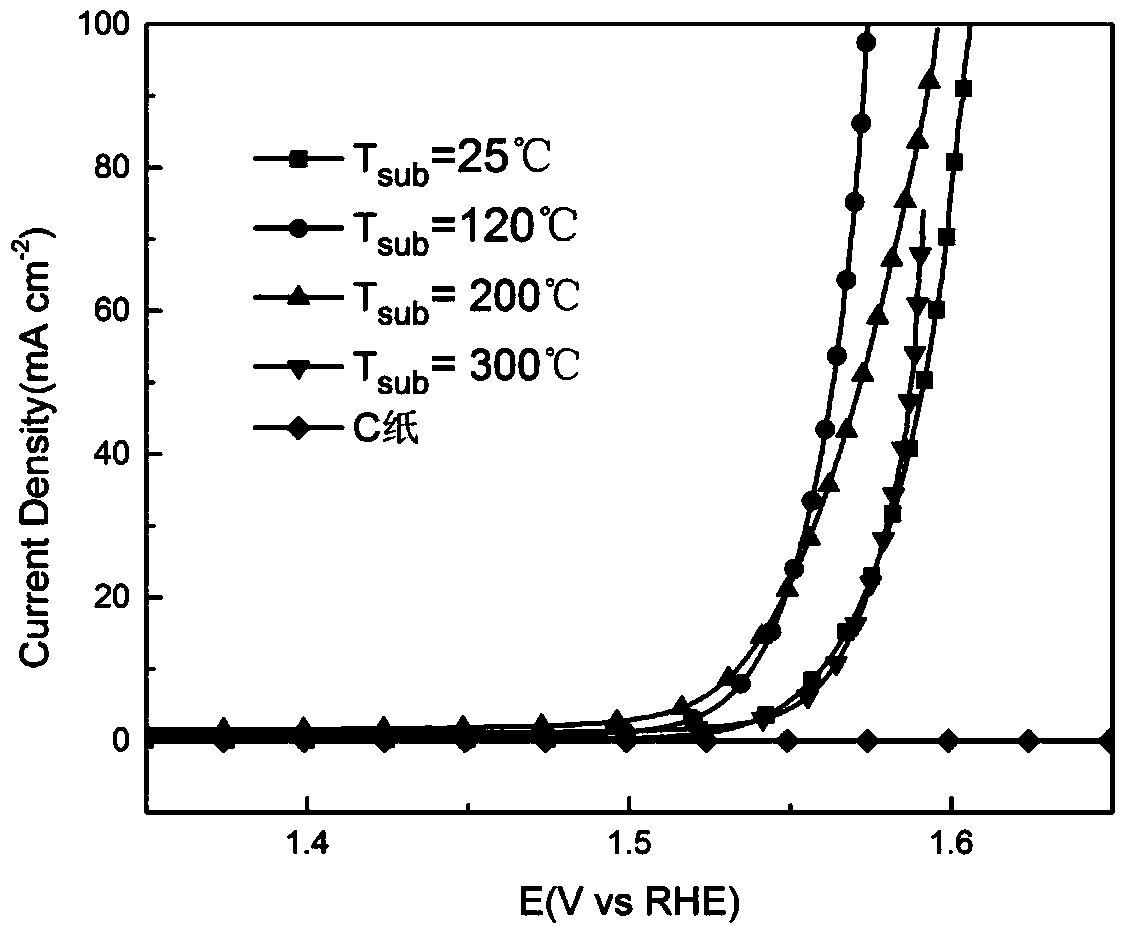

[0033] After characterization, the sample obtained in this example is completely amorphous and has good oxygen evolution performance. In KOH solution, when the current reaches 10mA / cm 2 The required overpotential is 330mV, and the chemical composition remains unchanged.

Embodiment 3

[0035] This embodiment prepares Fe in the same manner as in Example 1 40 co 40 Se 20 For amorphous thin film catalysts, the only difference is that the temperature in step 4 is 200°C.

[0036] After characterization, the sample obtained in this example is a mixture of crystal and amorphous, with good oxygen evolution performance. In KOH solution, when the current reaches 10mA / cm 2The required overpotential is 297mV, but the chemical composition changes before and after the measurement, that is, the state of the catalyst is unstable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com