Multifunctional mesoporous silicone solid-phase extraction agent and preparation method and application thereof

A technology of solid-phase extraction agent and mesoporous silica gel, which is applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems that are not suitable for the analysis of polar ionic drugs, and achieve the cost of preparation Inexpensive, strong selectivity and enrichment ability, solve the effect of low extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Dissolve 13.8g Pluronic P123 and 7.6g mass concentration of 35% concentrated hydrochloric acid in 250mL water, stir fully for 4h, after P123 is completely dissolved to transparent, add 24.8g ethyl orthosilicate dropwise under vigorous stirring, the mixture The solution was continuously stirred in a water bath at 35 °C for 24 h. Then the mixture was transferred into a reactor and hydrothermally treated at 120 °C for 48 h. After cooling, it was suction filtered and washed with water. Finally, the product was moved into a muffle furnace and calcined at 550°C for 2 hours to obtain mesoporous silica gel;

[0022] (2) Soak the obtained mesoporous silica gel in 3mol / L hydrochloric acid solution overnight, then dehydrate and activate at 160°C for 6 hours, cool and store in a desiccator for later use;

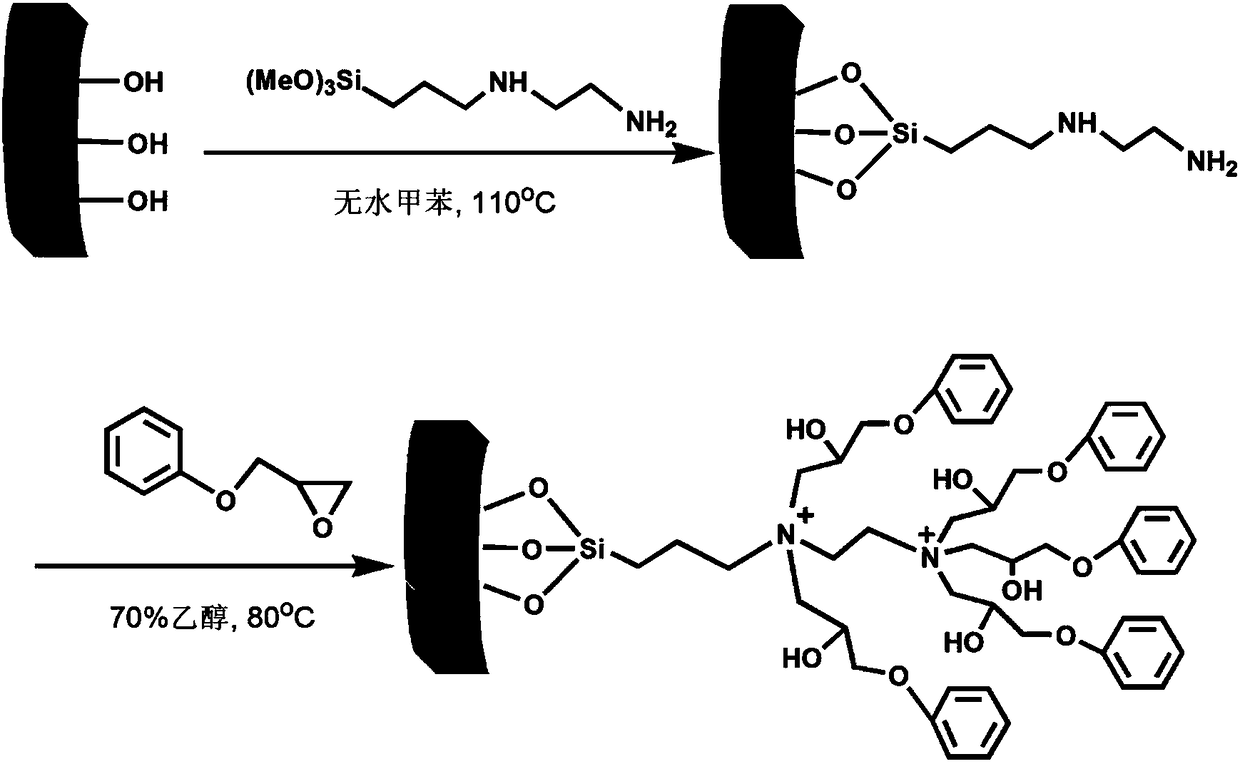

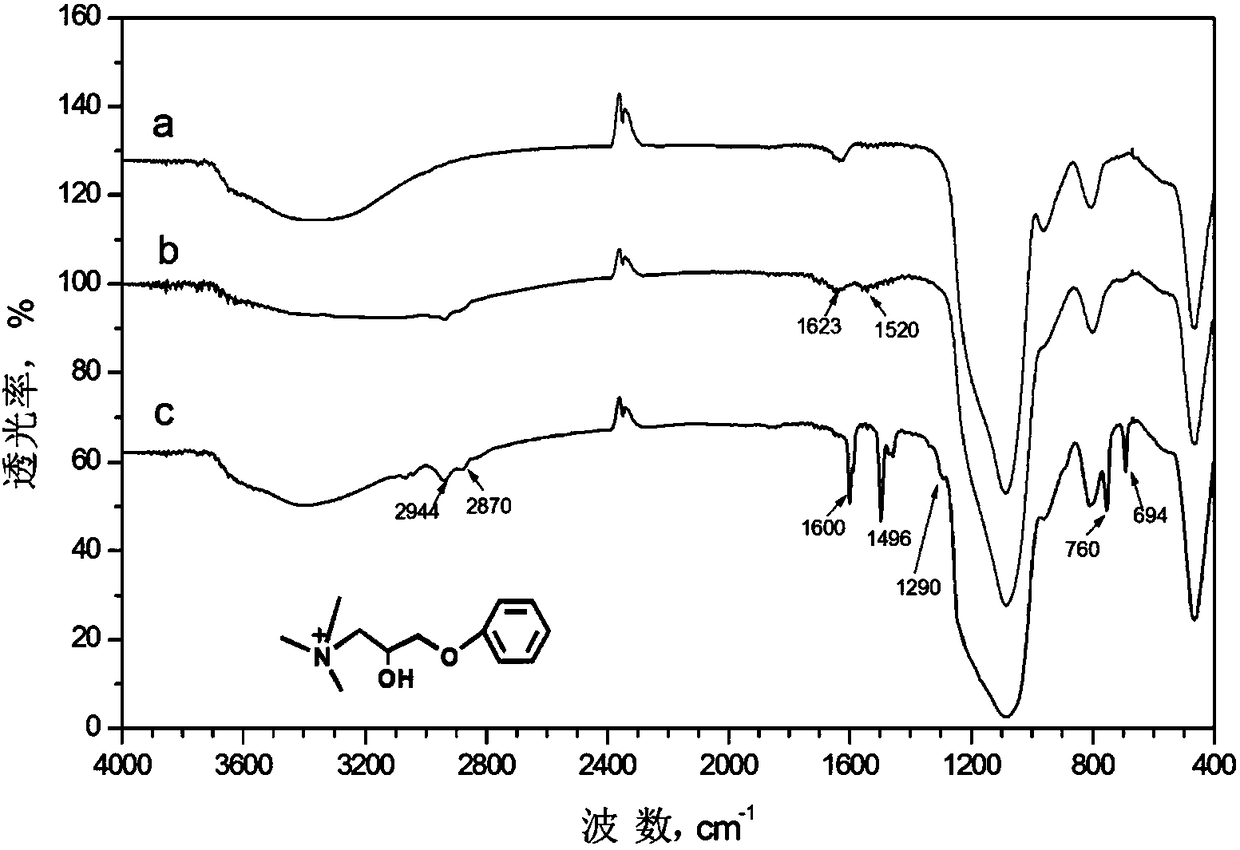

[0023] (3) Disperse 4g of the above-mentioned activated mesoporous silica gel in 110mL of anhydrous toluene, add 4mL of 3-(2-aminoethylamino)propyltrimethoxysilane under st...

Embodiment 2

[0025] Example 2: (1) Dissolve 13.8g of Pluronic P123 and 7.6g of concentrated hydrochloric acid with a mass concentration of 35% in 250mL of water, and stir thoroughly for 4 hours. After the P123 is completely dissolved to transparent, add 24.8g of ethyl orthosilicate dropwise under vigorous stirring ester, the mixture was continuously stirred in a water bath at 35°C for 24h. Then the mixture was transferred into a reactor and hydrothermally treated at 140 °C for 48 h. After cooling, it was suction filtered and washed with water. Finally, the product was moved into a muffle furnace and calcined at 550°C for 2 hours to obtain mesoporous silica gel;

[0026] (2) Soak the obtained mesoporous silica gel in 3mol / L hydrochloric acid solution overnight, then dehydrate and activate at 160°C for 6 hours, cool and store in a desiccator for later use;

[0027] (3) Disperse 4g of the above-mentioned activated mesoporous silica gel in 110mL of anhydrous toluene, add 4mL of 3-[2-(2-amino...

Embodiment 3

[0029] Embodiment 3: the preparation method of multifunctional mesoporous silica gel extractant of the present invention

[0030] The schematic diagram of the functionalization of the multifunctional mesoporous silica gel extractant provided by the present invention is as follows: figure 1 shown.

[0031] (1) Dissolve 13.8g Pluronic P123 and 7.6g mass concentration of 35% concentrated hydrochloric acid in 250mL water, stir fully for 4h, after P123 is completely dissolved to transparent, add 24.8g ethyl orthosilicate dropwise under vigorous stirring, the mixture The solution was continuously stirred in a water bath at 35 °C for 24 h. Then the mixture was transferred into a reactor and hydrothermally treated at 130 °C for 48 h. After cooling, it was suction filtered and washed with water. Finally, the product was moved into a muffle furnace and calcined at 550°C for 2 hours to obtain mesoporous silica gel;

[0032] (2) Soak the obtained mesoporous silica gel in 3mol / L hydroc...

PUM

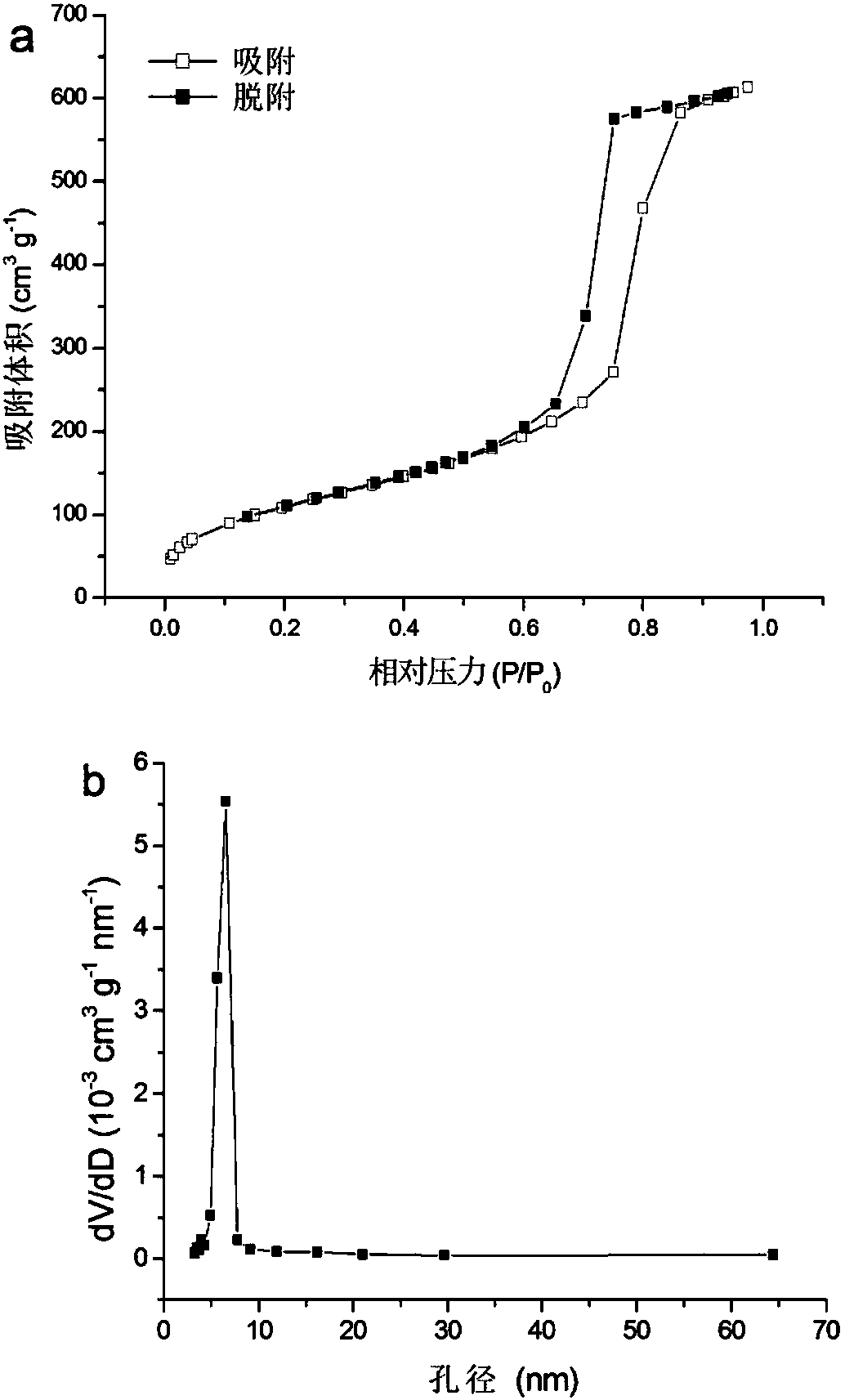

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com