Method for improving adsorption capacity of adsorbent prepared from printing waste liquid extract

A technology of adsorption capacity and extract, which is applied in the direction of chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve the problems of low adsorption capacity of adsorbent and large amount of adsorbent, so as to improve the utilization rate and porosity Uniformity, the effect of increasing the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

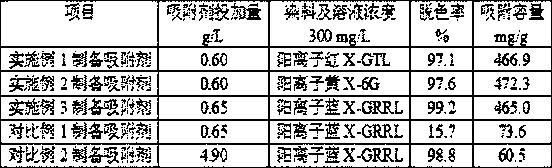

Examples

Embodiment 1

[0028] (1) Slowly add 98% concentrated sulfuric acid to the high-concentration water-based ink printing waste liquid, stir the reaction, reduce the solubility of the water-soluble polymer binder, and destroy its stability in water, so that the extractable substances in the waste liquid are just Condensed into insoluble fine solid particles;

[0029] (2) Stir continuously to reduce the viscosity of the waste liquid and prevent further flocculation of the generated fine solid particles. At the same time, slowly add 8 g / L sodium bicarbonate to the waste liquid to make it react with the waste liquid to generate micro-bubbles and make the bubbles Adhere to the fine solid particles in the waste liquid, and form a gas-liquid-solid three-phase contact interface between the fine solid particles;

[0030] (3) Stir continuously with the aid of 40 KHz ultrasonic waves, and at the same time heat to a temperature 5°C higher than the softening point of the binder, and gradually make the fine s...

Embodiment 2

[0037] (1) Slowly add 20% sodium bisulfate solution to the high-concentration water-based ink printing waste liquid, stir and react, reduce the solubility of the water-soluble polymer binder, and destroy its stability in water, so that it can be extracted from the waste liquid The substance just condenses into insoluble fine solid particles;

[0038] (2) Continue stirring to reduce the viscosity of the waste liquid and prevent further flocculation of the generated fine solid particles. At the same time, slowly add 5 g / L sodium carbonate to the waste liquid to make it react with the waste liquid to form tiny bubbles and make the bubbles adhere The fine solid particles in the waste liquid form a gas-liquid-solid three-phase contact interface between the fine solid particles;

[0039] (3) Stir continuously with the aid of 40 KHz ultrasonic waves, and at the same time heat to a temperature 20°C higher than the softening point of the binder, and gradually make the fine solid partic...

Embodiment 3

[0046] (1) Slowly add 98% glacial acetic acid to the high-concentration water-based ink printing waste liquid, stir the reaction, reduce the solubility of the water-soluble polymer binder, and destroy its stability in water, so that the extractable substances in the waste liquid are just right Condensed into insoluble fine solid particles;

[0047] (2) Continue stirring to reduce the viscosity of the waste liquid and prevent further flocculation of the generated fine solid particles. At the same time, slowly add 5 g / L potassium carbonate to the waste liquid to react with the waste liquid to form tiny bubbles, so that the bubbles adhere to the waste liquid The fine solid particles in the medium form a gas-liquid-solid three-phase contact interface between the fine solid particles;

[0048] (3) Stir continuously with the aid of 40 KHz ultrasonic waves and heat at the same time to a temperature 10°C above the softening point of the binder, gradually making the fine solid particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com