Preparation method for quickly processing pickled vegetables by cold pickling

A kimchi and fast technology, applied in the direction of food science, can solve the problems such as the inability to pickle the Sichuan kimchi flavor, the softening of the kimchi, and the impact on the quality of the kimchi, so as to achieve the effect of enhancing the added value of the product, the rich flavor and the crisp taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of preparation method of pickled vegetables processed quickly by cold soaking, it comprises the following steps:

[0027] (1) Preparation of pickle mother water bacteria powder: filter the fermented and mature old pickle water with 6 layers of sterile gauze, and carry out cold centrifugation at 6000r / min for 5min to collect the centrifuged sediment. The centrifuged sediment: skimmed milk powder: sorbitol: glucose: Tween=100:5:0.5:2:0.5 was mixed and then freeze-dried at -45°C cold trap temperature, 20°C plate temperature, and 24h freeze-drying time. Become kimchi fungus powder.

[0028] (2) Preparation of dehydrated salted vegetables: Screen the fresh radish used for fermentation, clean it up, blanch 1mm in boiling water after draining, remove the fresh vegetable's raw smell and kill the microorganisms on the surface of the vegetable. Add edible salt immediately after the vegetables are taken out of boiling water, sprinkle evenly on the surface, the salinity is ...

Embodiment 2

[0034] A preparation method for cold soaking and quick processing of pickles, the method steps and parameters are the same as in Example 1, only the formula of the spices in the preparation step (3) of the spice liquid is changed, 5 parts of garlic, 3 parts of ginger, star anise 2 parts, 0.5 parts pepper, 2 parts vanilla, 2 parts licorice and 1 part cardamom.

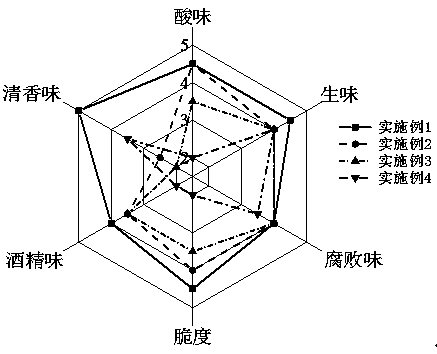

[0035] The fermented kimchi that was finally prepared was tested.

Embodiment 3

[0037] A kind of preparation method of pickled vegetables processed quickly by cold pickling, method step and parameter are all the same as embodiment 1, only adjust the mixing ratio of pickled vegetable powder, flavor emulsion and dehydrated salted vegetable in step (6), specifically adjust to 1 :10:100.

[0038] The fermented kimchi that was finally prepared was tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com